Examine a utility’s load curve over the course of a week and the trace looks like a roller-coaster. Demand for electric power peaks about 5 pm each day and declines to a low at about 2 am. Look closer and you see demand changing almost by the second. So there are two problems here that befuddle electric companies. One comes from having to deal with the large changes in demand as it grows and slackens throughout a 24 hour period.

The other is the almost second-by-second change to demand that leads to frequency variations. For instance, in brief periods when demand drops, generators may run fast so that frequency in the line rises over 60 Hz. And when loads come online, steam driven turbines slow a but and line frequency drops. This can play havoc with some customer equipment.

The wind industry offers a partial solution by providing some power during high demand periods. But this so-called peak shaving is not a perfect solution because even wind plants could be in a lull when power is needed. If there were a way to store the excess power, regardless of source, it would let wind plants put more turbines online for longer periods so boilers could throttle back. Short-term power storage would also let utilities really smooth out the power curves so line frequency stays closer to 60.00 Hz than it does at some periods.

A few applicants for these jobs include compressed air, flywheels, large batteries, and generating and storing hydrogen, reported on elsewhere in this magazine. Of course there are others such as fuel cells and ultra capaciators. The Electric Power Research Institute is looking into additional methods, but for the time being, those here appear the most promising.

Stimulus of compression

The Federal administration has begun doling out some $60 million to promote energy storage with the Department of Energy in particular announcing which companies will receive awards. One method for storing energy inexpensive off-peak power compresses air into underground reservoirs which can be quickly brought online as demand peaks.

Energy Storage and Power LLC (ES&P), Basking Ridge, NJ (espcinc.com) received a $20 million investment from the Public Service Enterprise Group Inc to test a recent modification to its compressed-air storage equipment already in service. Energy Storage says it has patented a method for storing compressed air which is more durable and less expensive than batteries. This technique is one proposed solution to the demand for power that varies over a 24 hour period.

The company says it focuses on developing projects that use its second generation Compressed Air Energy Storage (CAES2). Company CTO Michael Nakhamkin lead the design of the first generation 110-MW CAES plant in McIntosh, Alabama that has been operating for 17 years and says the utility has an availability record of about 95%.

Nakhamkin says the CAES2 comes from lessons he has learned and improvements to commercially available equipment. The company says it has several advantages over the first generation CAES technology. For instance, second generation equipment is based on off the shelf components and plant capacity scales from about 15 MW using above-ground tanks to over 400 MW using underground geologic formations.

Capital costs range from about $800 per kW for below ground storage to about $1,200 for small plants using above ground tanks.

Grid support is practically instant, says Energy Storage, during plant operation at some 30 to 100% of capacity. From cold shutdown, about 70% of rated capacity can be delivered in better than 3 to 5 minutes.

Flywheels

These generally use a rotating carbon-fiber composite rim levitated on magnetic bearings operating in a near-frictionless vacuum. The rim is fabricated from a combination of high-strength, lightweight fiber composites. The sturdy construction lets the flywheel spin at speeds to 16,000 rpm to store more energy than could flywheels made from metals. To reach operational speed, the units draw surplus electricity from the grid to power a permanent-magnet motor. The flywheel can spin for extended periods because friction and drag are reduced by magnetic bearings in the vacuum. Low friction means little power maintains the flywheel’s operating speed.

A series of flywheels can provide MWh-sized storage. When a grid needs power, momentum of a spinning flywheel drives its generator to convert kinetic into electrical energy.

The Smart Energy 25, a flywheel design from Beacon Power Corp., Tyngsboro, Mass., (beaconpower.com) seals a rotor in a vacuum chamber so it can spin at 8,000 to 16,000 rpm. To further reduce losses, the rotor levitates with a combination of permanent magnets and electromagnetic bearings. At 16,000 rpm the flywheel stores and delivers 25 kWh.

Although the flywheel can charge in 15 min and fully discharge in the same period, it will more likely be used 15 sec at a time because of the grid’s rapid and normal fluctuations. Beacon Power’s grid-scale Smart Energy Matrix is made of several units connected to store energy for utility applications. “This matrix can absorb and deliver megawatts of power for minutes, providing highly responsive frequency regulation for increased grid reliability,” says Beacon’s Gene Hunt.

“The units are capable of hundreds of thousands of charge-discharge cycles over a 20-year life, making them well suited to regulating frequency,” he adds. And an array of flywheels can be monitored and operated remotely as part of an intelligent grid. No hazardous chemicals or materials simplify permitting.

The company recently added 1 MW to an already working 2 MW facility that provides frequency regulation to the New England grid. The first 2 MW has been online since November 2008. In addition, The New York State Public Service Commission has granted the company a certificate for a 20-MW flywheel frequency regulation plant. Construction will complete within 18 months.

“Our flywheels provide a grid-stabilizing service and they do it faster and more efficiently than today’s conventional methods, most of which consume fossil fuel,” says Beacon President Bill Capp. One company challenge, he says, was proving the value of large-scale storage to investors without any projects to point to as examples. The company has applied for $47 million in DOE stimulus grants to build two more 20-megawatt plants, one in New York and another in the PJM (formerly the Pennsylvania, New Jersey, Maryland) Interconnection.

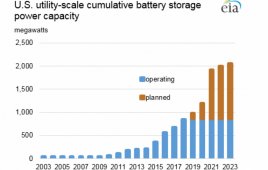

Batteries

At least four designs for large batteries are getting attention. One uses sodium sulfer, one is lithium-based, another uses a bromine solution, and a fourth with promise will soon leave the lab at a lower cost than the others.

North Carolina’s Duke Energy says it plans to match a $22 million federal grant to test batteries as devices for storing wind energy from its Notrees Windpower Project in Texas.

“Energy storage has potential to serve as a game-changer when it comes to renewable power,” says Duke Energy Generation Services President Wouter van Kempen. The 95-turbine Notrees wind farm has a peak energy production of 151 MW.

Southern California Edison Co. says it has asked for a $25 million stimulus grant to help Massachusetts-based A123 Systems Inc. (a123systems.com) build the world’s biggest lithium-ion battery.

The 32-MWh battery would be assembled using racks of smaller units at a substation in Southern California’s Tehachapi Mountains. The battery would counterbalance wind power sent from the mountains to the utility’s customers in the west and south.

A battery from Japan-based NGK Insolator, Baltimore, (ngk.co.jp/english) uses a sulfur as a positive electrode and sodium as a negative electrode. Beta alumina, a conductive ceramic, separates them. Connecting a load to terminals lets current discharge through the load.

The Electric Power Research Institute, the U.S. utility industry’s R&D consortium in Palo Alto, Calif, says such storage would allow widespread use of renewable power and make the grid more reliable and efficient. Announcements from utility American Electric Power (AEP), Columbus, Ohio suggest that grid storage equipment is ready for commercial deployment in the U.S. AEP has ordered three multi-megawatt batteries and set goals of having 25 megawatts of storage in place by 2010, and 40 times that by 2020. The AEP design uses NGK Insulator’s sodium-sulfur batteries and controls to manage the flow of ac power in and out of the dc battery.

AEP energy engineer Ali Nourai says the company and other U.S. utilities have confidence in the viability of such storage thanks to a demonstration project in Charleston, WV, where the utility installed a large battery in June 2006. Peak demand in Charleston’s summer and winter was overloading transformers at local substations causing blackouts. Rebuilding the substations to accommodate more power could have taken as much as three years. Instead, AEP spent just nine months installing a battery that charges during low power demand and delivers up to 1.2 MW for seven hours when demand peaks.

A more recent sodium-ion battery provides another practical option for storing power, says Carnegie Mellon University material science Professor Jay Whitacre. His startup, 44 Tech, will receive $5 million from the DOE to develop the idea.

Whitacre says the startup’s batteries could be cheaper and longer-lasting than current designs for the same use because sodium sulfate in his design is more abundant and less expensive than lithium. In addition, sodium sulfate is uses as a food preservative making it almost harmless to handle. To trim costs further, Whitacre plans operating at lower cell voltages than other battery chemistries.

Matt Rogers, senior advisor to Energy Secretary Chu, estimates the battery will handle large amounts of energy for about one-tenth the price of similar technology.

The change to sodium-sulfate electrolytes could also make it possible to eliminate much of the supporting material needed in conventional lithium-ion cells, again reducing costs. This is because increasing the ionic conductivity makes it possible to use thicker electrodes with fewer layers of separating and current-collecting materials inside the cell. Whitacre says the first battery will be ready for testing soon and for three or four years at different substations.

The final battery in this quintet also uses a flowing chemical electrode to store up to 50 kWh in a self-contained unit. Unlike the other batteries here, the ZESS (zinc energy storage system) is based on fuel-cell ideas, according to the company, and combines aspects from both battery and fuel cells. The battery represents an environmentally friendly and cost-efficient alternative energy storage, says developer ZBB Energy Corp., Menomonee Falls, Wisc, (zbbenergy.com)

One ZBB module stores 50 kWh. The ZESS 500 is said to be a 500 kWh ‘plug and play’ system consisting of ten of the company’s standard 50 kWh modules, with power electronics. The firm says the units are scalable and mobile. Each 50 kWh battery module is composed of three cell stacks, each with 60 cells in a series. Users can charge the battery from a variety of power sources at different charge rates and it can fully discharge repeatedly without damage. Modules are self-contained, and a control system takes care of energy storage and safety functions.

The company refers to the design as a Regenerative Fuel Cell (RFC) and adds that it relies on a flowing electrolyte with features such as:

• Chemical reactions that take place in the cell stack and excess electrolyte stores in external tanks.

• The predominantly aqueous electrolyte is composed of zinc-bromide salt dissolved in water.

• During charge, metallic zinc is plated from the electrolyte solution onto the negative electrode surfaces in the cell stacks.

The ZES500 is a bedmount of ten 50 kWh ZBB batteries, capable of storing 500 kWh. Facilities would use units of this sort by charging them during low-power-cost periods so power is available during at high cost times.

Bromide converts to bromine at the positive electrode surface of the cell stack and stores as a safe, chemically complex organic phase in the electrolyte tank.

Each cell stack has 60 bi-polar electrodes between a pair of anode and cathode-end blocks. It operates quietly and at ambient temperature.

Electrodes don’t take part in the chemical reactions. They are substrates for the reactions. That means no loss of performance from repeated cycling that often causes electrode material deterioration.When the ZESS discharges, the metallic zinc plated on the negative electrodes dissolves in the electrolyte and is available for plating at the next charge cycle. And it can be left indefinitely in a fully discharged state.

In one application, a ZESS 500 battery will store power generated by an 850 kW wind turbine that already provides half the power for Ireland’s Dundalk Institute of Technology Centre for Renewable Energy Project. This installation of a ZESS 500 with a wind application will let the campus operate independent of the electrical grid.

Filed Under: Energy storage

Just to correct the last paragraph a little: our Vestas V52 nowadays provides about a third of the campus power here at DkIT in Ireland. The campus has grown in the past few years. We’ve updated our online information! We believe that our ZBB battery is the first installation of its kind in Europe. We will happy to be corrected if anybody else has better information. We’ve a little more information at our own website. Niall McMahon, CREDIT (Centre for Renewable Energy at Dundalk IT).

What are the pros and cons of wind energy?

Mr. Brown:

You can record a range of pros and cons depending on who you speak with. On the plus side, first and foremost, it’s wonderfully clean. In addition, wind power generates jobs, increases our knowledge of weather systems, reveals weaknesses in conventional electrical equipment, stimulates the invention of new products, it pushes the design boundary of composites, encourages wise use of natural resources, and excites the imagination of many of us.

On the downside, like most everything else, it could be less expensive.

Paul Dvorak

Paul Dvorak

The Grand Coulee dam in Washington pumps water up into a reservoir behind the dam in periods of excess generation. Wind farms could collaborate with a system like that. The frequency regulation is no longer a problem. I think local neighborhoods should have their own flywheel system that takes all power generation (wind, solar, hydro, etc.) and stores it for that local area and puts it out when needed. This could take a load off the grid during peak hours and store excess generation.

Tim:

Thanks for the comment. The idea sounds like a great way to store excess wind power. Any turbine on the local grid could contribute to the pump power. Too bad it’s not more accessible to more wind plants.

Paul Dvorak

We have had the opportunity to work on these systems. Battery storage makes so much sense for when the wind in not available.

Gene:

The trick it seems to me is to switch from charge to discharge in about a second. Batteries and flywheels can do that. Then the question becomes, how much should be stored? If a lot, then a large cheap battery will have advantages. The free market will pick the winners.

Paul

Mr. Wright:

Most large batteries are expensive because their are designed for high energy density (for a battery) using costly materials. But a Prof. at Carnegie-Mellon U. is patenting a big battery that uses low cost materials and has a relatively low-energy density. If it’s stationary, its large size becomes a non-issue. We hope to report on it soon.

Paul Dvorak

In the second paragraph a statement is made that suggect that utilities are having line frequency change and causing customer problem with over frequency and under frequency. Can the author cite where this is currently occurring along with the magnitude of the frequency deviations?

You left out pumped storage hydroelectric- these facilities already exist.

Yes, I did leave out pumped hydro, because it is fairly well known and not available to most wind farms.

Do you know of any elevated reservoirs made just to hold pumped hydro?

Paul