By Andrew Ford; Professor Emeritus, School of the Environment

Washington State University

Renewable energy developers inevitably encounter one well-known problem: most renewable sources — such as wind or solar power — are variable in nature. They deliver energy according to natural cycles, not market forces. The swings in power production, however large or small, create problems for electricity grid operators who must balance supply and demand minute by minute.

For example, knowledge that wind will deliver an average of 1,000 megawatts (MW) over the next hour is of limited value to operators if delivered at a rate varying between 200 and 1,800 MW over the course of that hour. An expected weather system that arrives 20 minutes early or late creates further challenges for operators trying to balance output and demand to maintain a stable grid.

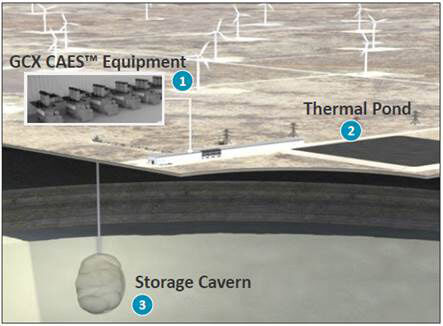

The GCAES prototype. General Compression’s Advanced Energy Storage system is set up as a prototype in Gaines County, Texas. Here, GCAES uses an underground salt cavern as an air reservoir and is powered by a 2-MW wind turbine.

A common technique for integrating wind is to employ natural gas-fueled combustion turbines, often called peaking plants. When an operator must provide plus or minus 1,000 MW of power to offset wind fluctuations, the operator contracts for 2,000 MW of combustion turbines. Half of the units are scheduled to run at any given time, with the other half kept in reserve.

Alternatively, the operator can increase output by as much as 1,000 MW by calling on the idle units to run when winds are lighter than forecast. But this is costly. Payments for energy actually produced are usually made in addition to wind and regular capacity payments.

Ideally, operators need flexible resources to offset forecasting errors and create a balanced supply chain — while keeping power costs in check for ratepayers. Many believe the answer to this challenge comes in the form of energy storage. Two North American energy storage companies, General Compression and NRStor, are among that group. Together, they’ve been working with the support of asset management group, Northwater Capital Management, to develop a proposal for energy storage in Ontario at a scale appropriate for the provincial grid.

Research has led the team to develop and test a fuel-free, compressed-air energy storage system that can:

- Provide value for ratepayers through the ability to deliver stored energy to integrate wind-generated electricity more efficiently into the Ontario grid. (This is an area of immediate need, as Ontario advances toward its goal of 10,700 MW of renewable generation capacity.)

- Deliver additional value through load leveling, or the ability to store energy at night when demand is low and inject it back into the grid when demand is high. Load leveling would reduce the need for combustion turbines and also lower costs to ratepayers.

The technology

General Compression has developed a grid-connected, compressed-air storage prototype, known as General Compression Advanced Energy Storage or GCAES. A prototype of this storage system is currently set up in Gaines, Texas. Powered by a 2-MW wind turbine, GCAES uses an underground salt cavern as an air reservoir.

System integration. This diagram shows General Compression Advanced Energy Storage System (CAES) integrated with a thermal pond, storage cavern, and wind farm.

The onsite turbine can also deliver power to the grid, and the compressors can draw power from the grid if necessary. The prototype facility can deliver energy at full power of 1.6 MW for a period of 150 hours before recharging.

A traditional problem for compressed air generation is that compression creates heat, which tends to expand air and make compression increasingly difficult. By contrast, when the compressed air is released to generate power, it rapidly cools and reduces the amount of energy available for extraction. It can also cause ice buildup in the equipment.

Some systems address this problem by burning natural gas to warm the de-compressing air. But this increases costs and produces carbon-dioxide emissions.

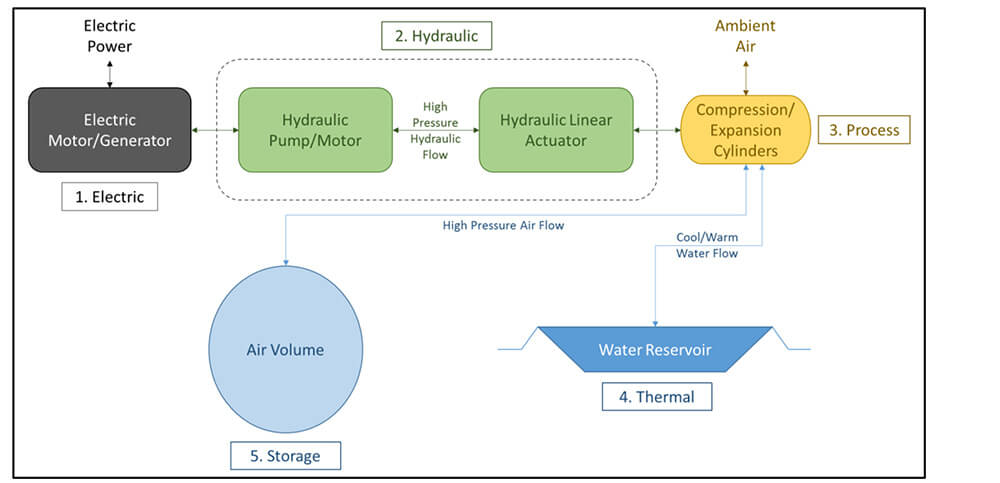

The GCAES system solves both the heating and cooling problems by capturing the heat produced by compression and channeling it into a water storage pond. The heat stored in the pond is then used to warm the released air during the generation cycle. This provides for greater energy from the expanding air and prevents the equipment from freezing.

Because the compressors are powered by wind, the system provides a source of fuel-free energy storage and power generation. Early calculations show the installed cost of long-duration storage is as little as one-tenth that of lithium-ion battery storage.

The proposal

Ontario has a number of salt caverns suitable for GCAES. But no technology is useful, no matter how innovative, unless it effectively fills a need in the marketplace. So NRStor partnered with a professor at Washington State University and created a model of Ontario’s power system to analyze the potential of integrating GCAES. They’ve shared this analysis with Ontario’s energy ministry and officials of the province’s energy agencies.

Storage would be especially useful in helping moderate the highest peaks in Ontario’s demand for generation. These peaks occur for only a few hours a day, during the coldest, darkest winter months, and during the hottest summer months. But supplying these peaks is expensive for electricity users. The province is forced to contract for additional generation that’s used for only a few hours a day, during a few months of the year.

GCAES process flow. This schematic depicts the Advanced Energy Storage system process

Currently, natural gas-fueled peaking plants supply high demands but require capacity payments whether in operation or not. A compressed-air storage facility can reduce the need for peaking plants by absorbing surplus energy during low demand periods of the day and returning it to the grid during the hours of peak demand. The potential savings are considerable. The model developed in this case estimates savings of $2.5 billion over 20 years. An alternate method of calculating the savings produces a similar result.

Just imagine: the system operator pays peaking-plant operators an annual fee of $120 per kilowatt of capacity, plus $18 per kilowatt in fuel management fees, for a total of $138 per kilowatt. A 1,000-MW plant has one million kilowatts of capacity, so the annual cost to ratepayers for 1,000 MW of peaking capacity is $138 million.

If peaking plants with a total capacity of 1,000 MW are removed from the system one year after GCAES comes online, the saving over the remaining 19 years of the facility’s operating life is $2.6 billion. This result is almost identical to the one predicted by the model. Ratepayers assume the entire cost for peaking plants, and would benefit from savings.

Simulations suggest that a GCAES facility would provide the greatest benefit for Ontario ratepayers if it were used to provide different services at different times of the year. The best results were achieved if it provided load leveling during the four months when demand is highest, while providing wind integration service for the other eight months.

Under the most likely supply and demand scenarios, the model shows that using a GCAES for a combination of wind integration and load leveling would deliver between $6.5 billion and $8.3 billion in reduced costs to ratepayers over the 20-year life of the facility.

Ontario’s Independent Electricity System Operator (IESO) recently awarded NRStor a contract to deliver compressed-air energy storage capacity services to the province’s grid. Once operational, this will serve as the first commercial CAES project in Canada.

Filed Under: Energy storage, Projects

This article talks a lot about savings but says nothing about costs. I highly doubt the savings described are net of costs, so what are the costs ? And while you’re at it, what are the round-trip efficiency of the CAES process and how much thermal energy is required to make it work ?