Editor’s note: This material development has potential to improve grid stability and efficiency, characteristics important to the wind industry.

SuperPower Inc. supplied its second generation (2G) high temperature superconducting (HTS) wire to the Applied Materials, Inc. superconducting fault-current limiter (SFCL) system to be installed for on-grid testing at the Knapps Corners substation owned and operated by Central Hudson Gas and Electric Corp. (Central Hudson) in New York. Applied Materials is one of many technology company’s involved in the energy industry that understand the benefits of 2G HTS technology as a viable and necessary part to revitalizing the power grid.

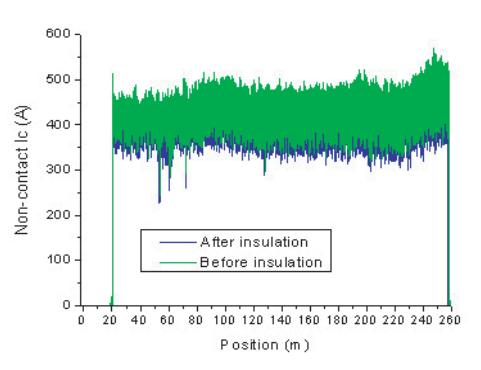

Wire is insulated with 0.025 mm or 0.050 mm thick polyimide, both with a ~ 0.050 mm silicone adhesive. Wrapping styles

are butt wrapped (no overlap) or an adjustable overlap of 0 to 50%.

SFCLs using high-temperature superconductors offer a solution to controlling fault-current levels on utility distribution and transmission networks. SFCLs provide enhanced stability and efficiency of the power delivery systems and reduce or eliminate wide-area blackouts, reduce localized disruptions, and improve recovery time when faults do occur. Unlike reactors or high-impedance transformers, SFCLs operate with low impedance and are “invisible” components in the electrical system during normal operation. It is only when a fault occurs that the SFCL inserts an impedance into the circuit (triggers the 2G HTS wire into a quench) and limits the fault current from transmitting further down line and causing significant damage to sensitive equipment.

In mid-April 2014, Applied Materials said it had completed assembly of a SFCL system for installation and on-grid testing at a substation owned and operated by Central Hudson. Other team members include the New York State Energy Research and Development Authority (NYSERDA), Three-C Electrical Co., Central Hudson, and SuperPower. System testing and evaluation is set to begin in May 2014 and will continue for one year. Performance data will be provided to the New York State Public Service Commission.

In today’s high voltage transmission network, the introduction of new generating facilities, independent power producers, and network upgrades can result in fault-current overduty on existing protective equipment. A variety of factors such as lightning, downed power lines, or crossed power lines also cause faults throughout the utility grid. Conventional solutions to fault current overduty problems such as the construction of new substations, splitting existing substation busses or multiple circuit breaker upgrades can be disruptive and very expensive. Other solutions such as current limiting reactors have unwanted side effects and can compromise system stability.

“The decline of the U.S. energy infrastructure, as well as that of the world, is out-pacing our ability to repair or replace the dated technology,” says Mr. Yusie Shirasaka, president and treasurer of SuperPower. “Using superconducting technology for energy applications, such as the SFCL, not only addresses the need for replacing the outdated equipment but also allows us to address the ever increasing demand for more power. Superconducting applications have significant benefits over their copper-based counterparts, including an enhanced capacity and increased efficiency in generation, transmission, distribution and storage of energy. The SFCL is a first-step in protecting existing grid equipment and for the future introduction of other superconducting devices such as cables, storage, transformers, and the combined SFCL-transformer.”

The company has provided the second-generation high temperature superconducting (2G HTS) wire for the European Union (EU) collaboration program, called Project ECCOFLOW. The ECCOFLOW SFCL was designed, built and tested by a team of fifteen European organizations that include five European utility companies.

SuperPower

http://superpower-inc.com/

Filed Under: News