In the development of the ST10, the company says one aim was to create a cost-effective low-weight design. To obtain this goal, the basic challenge of turbine up-scaling had to be overcome through several unusual design solutions.

The Norwegian company Sway Turbine has developed an eye-catching 10MW offshore wind turbine, the ST10. The unique features of this turbine are presented for the first time.

Sway Turbine’s CTO Eystein Borgen has presented the ST10 turbine at the 3rd International Conference on Drivetrain Concepts for Wind Turbines in Bremen, Germany. In his presentation Borgen shared information about the large diameter, direct drive permanent magnet generator, which has an ironless stator core and a unique generator and blade rotor integration.

“This is an exciting event for us, and we are pleased to be able to reveal more details about this technology, which we believe represents a cost competitive turbine alternative to the offshore wind market. Obtaining a lower Cost of Energy is crucial for offshore wind to achieve the position this renewable energy source deserves in the total energy mix” says Sway Turbine’s CEO Ms. Ingelise Arntsen.

In the development of the ST10, it has been the aim to create a cost-effective low-weight design. To obtain this goal, the basic challenge of turbine up-scaling had to be overcome through several unusual design solutions.

The ST10 offers an estimated 15 to 20% reduction in turbine cost compared to current state of the art, conventional design offshore wind turbines, and a considerable reduction in cost per kWh produced on wind-park level.

“As a technology development company, we are proud to present the ST10 design which has been developed by our engineers together with some of the most competent partners in the industry. We are now in the process of identifying the best industrial partner to bring this product to the market”, Arntsen concludes.

Principles of the Sway Turbine

Seven years of advanced dynamic simulations and engineering has let the Sway Turbine overcome the basic challenge of turbine up-scaling through several unusual design solutions.

The ST10 turbine has a large diameter permanent magnet ring style generator, directly driven by the turbine rotor. Each of the three pitching blades is mounted to an “A-frame” blade support structure that straddles the generator. The support structure legs terminate on two independent hubs which also function as the hubs for the generator rotor. The outer rim of the generator rotor is connected to the blade support structure, providing the means of transferring torque between the turbine rotor and the generator.

The ST10 turbine has a large diameter permanent magnet ring style generator, directly driven by the turbine rotor. Each of the three pitching blades is mounted to an “A-frame” blade support structure that straddles the generator. The support structure legs terminate on two independent hubs which also function as the hubs for the generator rotor. The outer rim of the generator rotor is connected to the blade support structure, providing the means of transferring torque between the turbine rotor and the generator.

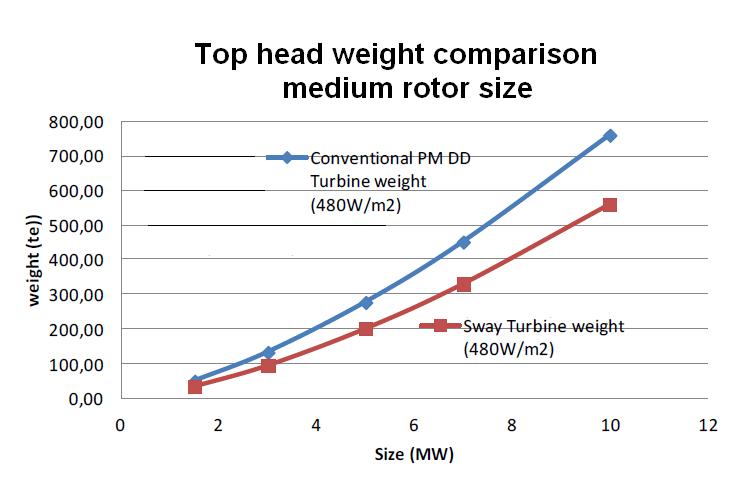

This combination of components results in a system that has a significant decrease in weight over conventional designs, and a net lower cost of energy. The configuration is particularly beneficial in offshore installations, where a premium is paid for each tower and foundation. The power generation system has therefore been optimized for offshore use including turbine, installation, impact on foundation system costs, operational and maintenance costs. It is designed to operate upwind on a fixed tower. It has a design life of 20 years. Arnsten’s presentation is at the url below.

Sway Turbine

www.swayturbine.no

Filed Under: News, Turbines

what is the status of the SWAY company and wind turbine project?

seems like the turbine loads will be too great and the spoke structure will twist and pinch the air gap between rotor and stator.

check out an even better idea called Indirect drive, view on you-tube Gaia offshore wind driven power plant.

It is true, the conventional wind turbines have some limit, as the size grows with higher power ratings, in excess of 10 MW for offshore technology. Research is needed to uncover that path.

i need details of windturbine design projects for colleges and home projects

10 MW, impressive! 100 of these when turning putting out the same power as an average nuke. My question, what are the limits? how big can these be made? At some point supporting a turbine securely against the wind would seem to be the limiting factor, the strength of the tower. Since the best “fuel”is higher up there must be some research already on this. Curious.