Paul Berberian / Predictive Maintenance Specialist / GTI Predictive Technology /

www.gtipredictive.com

It makes sense to rely more on early warning data from gearboxes and generators to prevent unplanned and catastrophic failures. Maintaining these critical assets is crucial to uptime and performance.

Predictive maintenance is a strategy in which maintenance is performed when one or more indicators show that performance is deteriorating or equipment will soon fail. When applied to a turbine that usually receives time-based maintenance but is running well, it suggests rescheduling time-based tasks for later because they are unneeded. This also eliminates the possibility of introducing a defect into the system.

Predictive Maintenance is the core of reliability maintenance. Technologies such as vibration analysis, motor-current signature, ultrasound, and oil analysis are used to assess machinery health and predict future failures. Prediction of failures allows planning maintenance on the user’s schedule, not the machine’s.

Tablets present new maintenance possibilities

VibePro is an iPad-based vibration analyzer from GTI Predictive Technology and illustrates one wind industry application for the tablet. Among other apps, it runs VibePro7, a vibration-based predictive maintenance program.

So what do tablet based solutions offer? First is cost. Tablets are priced around $500. and that figure is coming down. Their processing power is typically greater than that of an average single-purpose data collector. Another huge cost-reducing factor is the software applications or apps developed for each technology. Once a maintenance company owns an app, they own it forever. That means the app software is free to the user after the purchase of the first unit. Upgrades are free through the online App store – and they come automatically, with alerts on your tablet when they are available.

Second, the wide variety of technologies can be developed as apps – vibration, infrared, balancing, ultrasound, motor testing, laser shaft alignment – all can be apps that run on a single platform. Need a new technology? Contact the vendor for any hardware and download the app.

Another example of iPad based software is the laser shaft alignment app for VibePro. This guides uses through the steps necessary to complete an alignment using the iPad. Although the picture is of a motor, it could be a gearbox or generator.

Third, tablets are not purpose built. They can function as whatever tool you want it to be that day. Because all of the capability is developed in software, it is simple to upgrade because most upgrades are free through the App store. And from a developer’s perspective, it is simple to add new functions and capabilities as customers ask for them. Unlike conventional software, there is no need for a list of upgrades that will be included in the next version of hardware that you have to purchase as an upgrade.

Suppose you drop your tablet. No problem. Go to the local computer store, get a new one, and sync up your apps by re-loading your data from the cloud. It is less expensive and certainly takes less time than sending your display unit back for repair and waiting two to three weeks to get it back.

What else can we do with a tablet?

- Store and recall preventative maintenance checklists

- Produce photo and video documentation

- Carry inspection checklists

- Generate integrated reports with multiple technologies

- Watch training videos

- Consult complete user manuals

- Reference maintenance procedures

- Review work orders with parts lists and specifications

- Whatever you can think of

One tablet serves multiple technologies and provides new technologies and upgrades when you want or need to.

A detailed example for an iPad

Our company has developed apps for the iPad for vibration data collection and analysis, rotor balancing, and laser shaft alignment. The most recent is VibeCapture, advanced vibration analysis software. It is a vibration analyzer that collects and process vibration signals from industrial machinery and allows a deeper look into the vibration data.

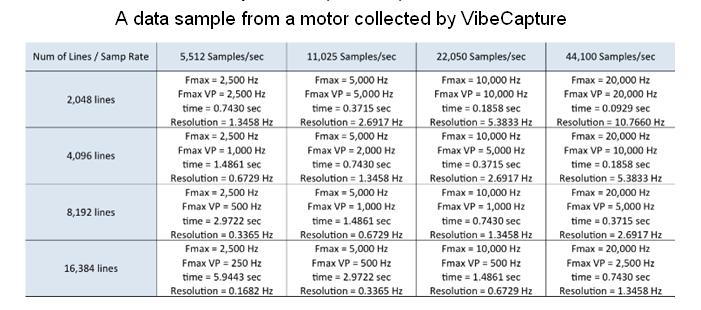

VibeCapture takes a multi-second capture of the vibration data, including time-waveform data. This data can be converted on screen to display the vibration spectrum as velocity, acceleration, or displacement. Selectable Fmax and sample rates let users select the resolution necessary to detect potential problems, down to 0.17Hz.

Collected data can be stored and viewed at a later time on the iPad, including time-waveform data. Analysis tools include cursors, zoom in and zoom out. Different portions of the time wave data can be selected to create spectrum data. The software features a selectable 1kHz high-pass filter for time waveform data. VibeCapture includes selectable Fmax settings and windowing options. Data can be displayed in Hz or CPM in either metric (mm/s or micron) or Imperial units (ips or mils).

Collected data can be stored and viewed at a later time on the iPad, including time-waveform data. Analysis tools include cursors, zoom in and zoom out. Different portions of the time wave data can be selected to create spectrum data. The software features a selectable 1kHz high-pass filter for time waveform data. VibeCapture includes selectable Fmax settings and windowing options. Data can be displayed in Hz or CPM in either metric (mm/s or micron) or Imperial units (ips or mils).

Data from the software can be sent to a cloud server for remote viewing in our VibeCapture Web App. This viewer includes the same analysis tools as VibeCapture on the iPad. When connected by WiFi or cellular, the push of a button instantaneously sends the data to analysts anywhere in the world. The VibeCapture Web App works on both PC and MAC machines. As with all company technology, updates to the app are free in the App store, including future product enhancements and added features. WPE&D

Filed Under: O&M, Training