The technology will be applied to three wind turbine drivetrains at Rocky Mountain Power’s 99-MW High Plains Wind Project which is located on both sides of the Albany and Carbon county border near McFadden, Wyoming.

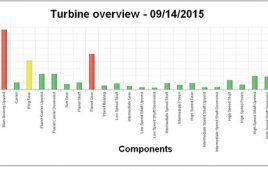

Condition monitoring made easy to read

John Ugland / Technical Account Manager / Renewable NRG Systems What makes a good condition-monitoring system for the wind industry? One that lets users derive operational value. We could argue that hardware, sensor placement, and storage servers all play a critical role in the value chain of CMS, but what is really important in a…

How is condition monitoring changing in the wind industry?

Unscheduled maintenance and turbine downtime are costly issues in the wind industry. Condition monitoring systems, or CMS, have provided one answer to help detect damage or component failures in turbine machinery often before they become serious problems. While wind-farm owners once considered CMS as a nice advantage, these systems are now becoming a necessity…

Condition monitoring: There is really only one right way

David Clark / President / CMS Wind Condition monitoring gets accolades outside the wind industry because of the value it brings to lowering O&M costs. Here’s why many in the wind industry come up short. Suppose you have recently realized the cost justification for condition monitoring. Influencing the decision is that other vertical markets already…

Webinar: Day-to-day condition monitoring for a large fleet of wind turbines

This webinar describes some of the challenges faced when monitoring a large fleet of wind turbines. Factors such as different turbine and gearbox types, different condition monitoring systems (CMS), geographically dispersed sites and variations in maintenance practice all make the job of a monitoring engineer a difficult task. Romax utilize in-house software called InSight Fleet…

Webinar: Following the Wind Turbine Condition-Monitoring Circle

Live webinar is Tuesday, July 22 at 2 PM Eastern. Data from a Condition Monitoring System (CMS) in a wind turbine travels to the analyst, then to purchasing and O&M, who then sends it back to the wind turbine with a technician who will perform some action. You can see that CMS data affects many…

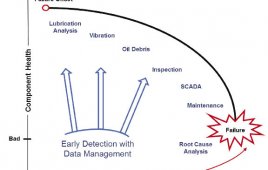

Establishing a perspective for a proper condition monitoring scheme

Michael Lenz / Process & Asset Manager/Asset Maintenance & Condition Monitoring Frontier Pro Services/ www.frontierpro.com While the wind industry is in the midst of adopting more advanced maintenance strategies, it is clear that machine condition monitoring will play a major role reducing life-cycle costs. It goes without saying that one of the conditions to monitor is the…

Managing drivetrain health by managing data

Larry Jacobs/ Marketing and Sales Manager/North America/ Romax Technology/www.romaxtech.com The U.S. wind industry is entering a transitional period in which more focus is placed on O&M strategies than expansion. One can easily see results in the attendance increase at various O&M conferences. Strategies that can make an impact in both operations (increased production) and maintenance…

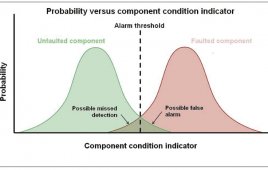

Evaluating the accuracy of condition-monitoring systems

Brogan Mortan / Chief Technology Officer / NRG Systems / www.nrgsystems.com There are many different condition-monitoring systems available that provide information on the current health of your wind turbine. Unfortunately there is no yardstick to evaluate and compare the performance of these different systems. Germanischer Lloyd maintains a certification process for vibration-based and oil debris…

Condtion Monitoring: Condition monitoring horror stories

Article by David Clark, condition monitoring specialist, Bachmann Electronics, www.bachmann.info Condition monitoring, now more than ever, plays a huge role in the reliability of wind assets. With the number of turbines coming out of warranty and the Production Tax Credit soon to die, how do you keep an asset available, productive, and reliable as it…

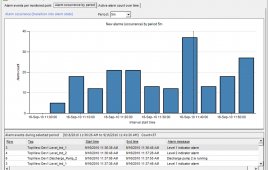

Free software available for alarm management and notification

Exele Information Systems, a developer of manufacturing and process control software, has made availabile a free version of its TopView Alarm Management and Notification software. TopView Free is a non-expiring version of TopView intended for applications with at most five monitored points. It provides one Remote Viewer (TopView client) connection. There are many processes…

Alarm software texts you when things go awry

TopView software lets users configure alarms, monitor remote processes, signal notifications, and more. The software is a comprehensive, cost-effective alarm management and notification program that’s useful when data must be monitored, such as in wind turbines and other non-manned facilities. The software lets users quickly respond to abnormal conditions. Users can customize notification messages and…

Three ways to improve performance and reliability

There are three methods for monitoring wind-turbine operations: wind-conditions monitoring, performance monitoring, and condition monitoring. The terms are thrown around so much that many in the industry are confused. Although the terms describe different tasks, they have the same goal: performance and reliability of the wind assets. An automotive analogy may be useful. For instance,…

Detecting Ice on Wind-turbine Blades

Nick Harper Applications Manager Blade Sensing Systems Moog Inc. www.Moog.com Cold weather presents special problems for wind turbines. Inside the nacelle, low-viscosity lubricants keep the gearbox turning and enclosure seals to keep moisture and ice off electronic components. But outside the nacelle, things are different. Ice easily forms on turbine blades possibly adding hundreds…

What is wind turbine condition monitoring and how is it useful?

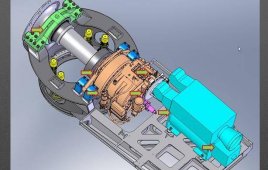

Condition monitoring is one way to keep tabs on all the equipment in a nacelle without a daily visit. SCADA systems provide some of this information, but a properly applied condition monitoring system provides more detail. The idea is to mount sensors on bearings, gearboxes, and generators. Pressure sensors can tell that the hydraulic system…

Prepping your wind farm for condition monitoring

David Clark Wind Consultant El Dorado Hills, Calif. Here’s a little secret: You can probably use anyone’s condition monitoring on a single turbine and get data good enough to predict basic failures. But expand the monitoring scope to several turbines or multiple sites and everything changes. To cost justify outfitting a 100-turbine farm…

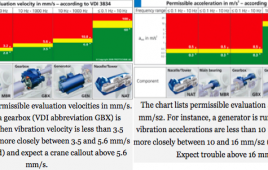

Finally, ISO Guidelines for Condition Monitoring

Alex Nino, LUDECAwind, www.ludecawind.com Characteristic valuesThe VDI guideline separates drivetrain components into their main groups and assigns overall vibration values to the most important ones. These component-specific vibrations can be classified and identified. The VDI 3834 is based on statistical analysis of vibration measurements from more than 450 wind turbines, and defines threshold values in…

What to expect from oil sensors and sampling

The three drive-train components that fail most frequently are the main bearings, gearboxes, and generators. All are lubricated, yet oil analysis focuses only on the gearbox.

Avoid maintenance surprises: Summit 2010, Sept 7 to 9

SmartSignal, a condition monitoring firm, will host its Summit 2010 on Sept 7 thru 9 at the Fairmont Hotel, Chicago. Find more conference details, download a pdf agenda, and register at: www.smartsignal.com/summit.aspx At Summit 2008, over 200 SmartSignal customers gathered to discuss best practices, hear about product developments, listen to industry gurus, and network with…

Misalignment, looseness, and imbalance are all correctable problems

While condition monitoring technologies can track many signals, its purpose boils down to detecting wear and preventing the eventual failure of monitored components. Not all megawatt-class wind turbine drivetrains are monitored with the intent to catch degrading components. A few frequently encountered conditions are not caused by wear, making them correctable. These conditions, when left…