Gearbox Express, the only independent company in North America solely focused on providing down-tower, wind gearbox remanufacturing solutions, has named John McKay Vice President of Operations.

Gearbox Express lets its true colors fly

Gearbox Express showed its true colors by painting a newly remanufactured gearbox with stars and stripes to help further celebrate United States’ independence as it was installed the week of the holiday.

Short gearbox life now steadily lengthening as technology matures

Two companies recently announced improvements to gearbox life that stretch their working life to much longer periods.

Gearbox Express School teaches gearbox repair

Gearbox Training school is a two-day, hands-on training course taught by top gearbox repair technicians, designers, and consulting engineers. July 11 and 12, 2017

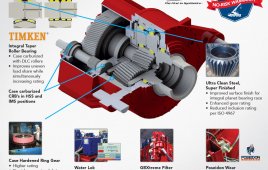

Gearbox Express unveils its Revolution 2.0

The top features of the Revolution 2.0 gearbox include A redesigned planetary gear and bearing interface, in which the bearing outer races are machined into the gear.

Poseidon announces partnership with Gearbox Express

Today Poseidon Systems, LLC announced a supply agreement with Gearbox Express, North America’s largest independent remanufacturer of gearbox assemblies and mainshafts for the wind turbine industry.

Gearbox Express opens new and 2x larger HQ

Gearbox Express along with wind energy industry leaders including Tom Kiernan, CEO of the American Wind Energy Association (AWEA), state and local public officials, recently celebrated the official grand opening of its new 75,000 square-foot facility in Mukwonago, Wisconsin.

2015 Innovators: Founders of Gearbox Express

Brian Halverson, Bruce Neumiller, and Brian Hastings Gearboxes have been a headache for the wind industry ever since turbines passed the 1-MW size over a decage ago. If that was not bad enough, the root cause of many problems eluded engineers until recently. While the industry wrestled with the problem, the only solution it knew…

What I learned in gearbox technology class

You might think it strange that a company with the mission of repairing and improving wind-turbine gearboxes would share what it has learned about the machines. But that is exactly what Gearbox Express and Romax Technology did recently with me, and many others throughout the year. It’s good for the wind industry. After two days of…

Webinar: New Ideas for Repairing Gearboxes and Generators

Wind-turbine-gearbox and generator failures have been a challenge to the wind industry for years, but engineers at companies that design, refurbish, and study them say they have a handle on the real causes of the failures and how to repair them. Some research has focusing on oil contamination, shock loads, and heat as a few…

Gearbox Express introduces “Revolution” to address common failure modes

Gearbox Express is introducing its Revolution gearbox upgrade. It’s a set of upgrades and a new thought process for wind energy gearboxes from 1.5 to 2.3 MW. Developed by the team at GBX, Revolution addresses the most common premature failure modes in gearboxes. “The Gearbox Express team has seen many gearbox failures with most having…