This section submitted by Ashley Crowther, Global VP – InSight, Romax Technology Modern gearboxes provide greater reliability to the wind-energy industry thanks to improvements in their design and operation. These include better bearing selection, design process, manufacturing quality, transportation, lubrication systems, and end-of-line testing. Reliability issues will never completely go away, but staying on top of…

Webinar: New Ideas for Repairing Gearboxes and Generators

Wind-turbine-gearbox and generator failures have been a challenge to the wind industry for years, but engineers at companies that design, refurbish, and study them say they have a handle on the real causes of the failures and how to repair them. Some research has focusing on oil contamination, shock loads, and heat as a few…

How are gearboxes used in wind turbines?

Gearboxes are arguably the most important component in wind turbines. Their reliability is paramount, especially as turbines grow in size. OEMs now focus on proper load assessing and ensuring all drivetrain components can function properly. A better understanding of the loads on a wind-turbine gearbox is one lesson the industry has learned. For instance, the…

Version 2 of workshop-on-wheels repairs gearboxes in three days

If you can’t bring a damaged gearbox to the shop, Moventas will bring the shop to the gearbox. A few months ago, gearbox manufacturer Moventas took the wraps off its mobile service unit (MSU) which is actually a gear-repair shop in a trailer. This 20-ft. workshop-on-wheels let repair crews refurbish most of a gearbox without…

What to do about rising rare-earth prices

By Panu Kurronen, Product Manager, The Switch The growing global demand of rare earth metals combined with China’s ever-tightening grip on the material keep pushing up magnet prices. While we at The Switch don’t think the price trend can last too long, we understand that the matter is of great concern for the wind power…

Entrepreneur Proposes Wind-Turbine Gear Factory For Indiana

You might think the U.S. has lots of gear-making capacity, so why would a start-up envision a factory capable of more of the same? The answer lies in the size of the gears planned by Vela Gear Systems CEO Noel Davis. Gears required in the wind industry can be in excess of 6 ft in…

How are gears & gearboxes used in wind turbines?

Gears and gear manufacturing: Uncontrollable and highly variable wind forces adversely affect the performance and reliability of planetary gears inside wind-turbine power transmissions. A couple developments can lower maintenance on rolling elements and carry greater load in a planetary gearset. The first idea is to equalize gear loads, reducing internal stresses and significantly extending wind…

Trends in gearboxes

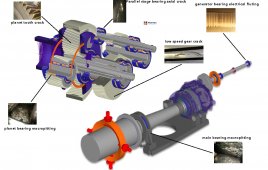

Despite the recent surge in wind-turbine announcements regarding direct drives, gearboxes are not going anywhere. They will remain a necessary component in many turbines, and so are pushing trends in several directions—toward lighter overall turbine weight, improved durability, and design for maintenance. “After ten years of research and study, we know why early gearboxes did…

Portland wind gear assembly kicks off

Wind gear manufacturer Moventas kicked off its USA assembly operations by expanding its existing facilities in Portland, Oregon. As of February, domestically assembled wind gearboxes will be available in North America. Initial capacity will be 200 MW, while the company continues to build even larger capacity in the Midwest area.

Re-building a better gearbox

As OEMs build larger wind turbines, they push the bounds of what’s possible for a 20-year service life. Occasionally, the boundaries push back with failures, often of gearboxes. Technicians at Broadwind Services, a division of Broadwind Energy in Abilene, Texas, say they can fix those broken gearboxes and make them better than new in a…

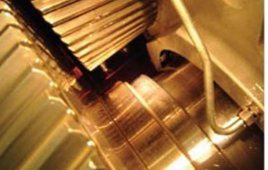

Gearbox lube for wind turbines

One way to improve wind-turbine efficiency is with proper gearbox lubricant. Dow recently introduced the UCON GL-320 lubricant for wind turbine gearboxes and those in other applications. The high viscosity index of the lube, addresses the issue of cold weather causing high lubricant viscosity without the need for additional VI improvers. It has higher heat…

Large part machine shop ready for turbines

After years of supplying the plastics machinery business and other companies in the industry, Milacron Machining, Mt. Orab, Ohio, is now applying its precision machining expertise to produce large, complex parts for the wind power market. “We have machined components for 2.5 MW and 1.5-MW gearboxes including housings, and planetary carriers,” says plant manager Jim…

Gearbox manufacturer opens wind-turbine service center at Vernon Hills, Ill.

ZF Services, the aftermarket business unit of ZF Friedrichshafen AG, now offers wind turbine gearbox services out of its Vernon Hills, Ill. remanufacturing and parts distribution center. With the addition of the Vernon Hills, Ill. facility, the company now operates six wind turbine gearbox service centers around the world, with the Dortmund, Germany service center…

Dow lubricant brochure for wind turbine gearboxes

The Dow UCON™ GL-320 lubricant was developed for wind turbines, though it can also be used for other types of gearboxes. Turbines can shut down in cold weather because of filter failures resulting from high lubricant viscosity. UCON™ GL-320 has a higher viscosity index to address this issue without needing additional VI improvers. The lubricant…

Excel Gear Announces Two Key Appointments

Excel Gear, Inc. of Roscoe, Illinois announces the appointment of Denis Bermingham as the manager of manufacturing engineering and special projects, plus William “Bill” Powers as the company’s marketing manager. Both appointments were made by company president N.K. “Chinn” Chinnusamy, who noted these hirings were made as the result of the company’s recent growth and…

Automated gearbox testing builds in consistency

A gear manufacturer shows how it automated formerly time-consuming manual tests. William L. Winterbauer, Ph.D. Principal Engineer QED Services Ann Arbor, Mich. The U.S. military has demanding requirements for the hardware it needs. Take, for instance, a set of gearboxes built by Excel Gear Inc., Roscoe, Ill, for missile launchers on the U.S. Navy’s new…

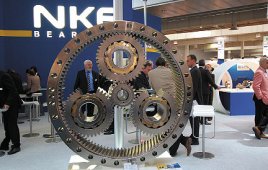

Modular bearing for planetary wind turbine gearboxes

Bearing specialist NKE Austria has developed a modular bearing system for planetary gears in wind turbine gearboxes. The modular concept is based on single-row cylindrical roller bearings of the company’s RN range, which do not have an outer ring. These bearings are equipped with a one-piece solid brass cage, which is guided by the inner…

Website for those blue alpha gearboxes

The company that designs and manufactures the blue alpha gearboxes, Wittenstein, Bartlett, Ill, has launched a new website, that it says better serves users and markets with an improved online feel. The company says the new website is phase 1 for improving its customer service to meet market’s needs. Current features include individual product pages…

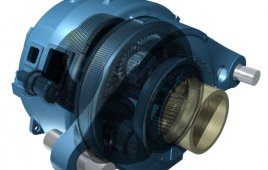

Speed increasers for wind turbines

Wind-turbine gearboxes from GE Drivetrains, Erie, Pa., span four designs that handle 1.4 to 2.9 MW. On the low end, for instance, the CP 1.8 is a one stage compound planetary with one stage parallel shaft. The high end uses a two planetary (2P) gear trains. Middle two units handle from 1.8 to 2.3 MW…

GE Drivetrain sets up shop in China

GE Drivetrain Technologies, a unit of GE Transportation, and A-Power Energy Generation Systems in China have signed two letters of intent. One is to have GE Drivetrain Technologies supply A-Power, Beijing, with 2.7-MW wind-turbine gearboxes and a second establishes a Joint Venture partnership for a wind-turbine gearbox assembly plant. Under the first agreement, GE Drivetrain…