HYTORC, which aims to make industrial bolting safer and simpler, provides a complete suite of on-site services to improve productivity through scheduled calibrations, repairs, preventative maintenance, loss prevention, and operator training. The company currently offers the largest mobile service fleet in North America, helping to eliminate project downtime or potential losses associated with shipping tools…

The LION Gun offers precision bolting system with built-in data recording

HYTORC aims to make industrial bolting safer and simpler. To this end, the company recently introduced the LION Gun, which it describes as the world’s first affordable precision bolting system with built-in data recording. Simply set the desired torque output on the LION Gun’s display and pull the trigger to get precise, repeatable torque without…

Hytorc takes the wraps off its digital pneumatic torque tool

The jGun DIGITAL Pneumatic Torque Tool from HYTORC is the world’s first torque-adjustable pneumatic multiplier with a digital readout and FRL-free operation.

Ergonomics are the real hazard of some bolting tools

Wind techs also work in hazardous environments using bolting tools and may face similar risks.

HYTORC gets permission to come aboard the Comanche Maxi Yacht

HYTORC was asked to devise a plan for fastening the Comanche’s keel to the interior of its hull, where it then attaches to a hydraulic cylinder.

HYTORC introduces newest LION, a consumer tool

HYTORC’s LION-.7 – has a ¾-inch drive, to deliver greater torque for larger applications. The LION-.7 provides a minimum torque of 150 foot-pounds and a maximum of 700 foot-pounds.

Just launched HYTORC Technologies will focus on ‘next generation’ industrial hydraulic pumps

HydroWer, which over the past four decades has become an international leader in the creation of hydraulic technology, including pumps, gauges, compensators and valves. Hytorc

What areas of a wind turbine require bolting and what tools are most useful?

Electric torque wrenches operate on batteries and up to 220 Vac.

HYTORC unveils its first consumer tool, a lithium ion battery-powered torque gun

The 18-volt, 4.1 Ah torque gun is just 7 pounds (with battery) and designed for applications with bolts 3/8-inch to ¾-inch in diameter and requiring 25-250 foot/pounds of torque. The product carries a manufacturer’s suggested retail price of $2,499.

Hytorc ICE bolting system sports built-in auto release, prevents lockups

With its innovative design, the tool is able to release pressure after bolting for quick movement from nut to nut, improving operator efficiency and safety. It is also the only hydraulic bolting system that allows positioning without constraints from hoses and reaction members.

Hytorc offers on-site mobile service repair, calibration, and more

On–site calibration and repair eliminates down time in production and maintenance environments, and prevents the loss of tools in transit, says HYTORC.

New torque tools call for a technician’s upgrade

Tools changed with hydraulic capability, then electric versions, and more recently the idea of a bolting system entered discussions.

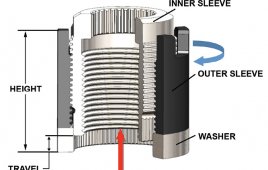

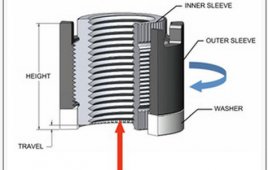

Hytorc’s bolting system needs no hoses, cords, or reaction arms

HYTORC’s 36-V battery powered torque guns combined with the HYTORC Washer are the ultimate solution, says the company, for portability and convenience in industrial bolting.

Bolting company HYTORC expands its customer service department

HYTORC continues to grow with a recent department addition to its Mahwah, N.J., facility.

HYTORC’s bolting products demonstrated at Power-Gen

HYTORC, the world’s oldest and largest manufacturer of industrial bolting systems, has a unique combination of industrial bolting tools and fasteners that will help

What’s new in bolting technology?

At a recent O&M conference, the topic of technician retention came up. Among the several suggestions was making their jobs easier with service lifts and lighter tools. This discussion deals with such tools. A lighter hydraulic pump The right tools let wind crews uphold safety, improve efficiency, and minimize their environmental impact. These goals ensure…

Engineered nut provides accurate, repeatable bolt load

Jason Junkers / Chief Operating Officer / HYTORC More than 45 years ago, a nut was considered “tight” when a hand tool could turn it no more. This eventually led to time-consuming maintenance down the road because few options for measuring “tightness” were available. So, nuts came loose, unexpected shutdowns were required for maintenance, and…

HYTORC, local dignitaries cut ribbon on John K. Junkers International Distribution Center in South Hackensack

Eric and Jason Junkers, along with elected and community leaders, recently cut the ribbon on HYTORC’s new John K. Junkers International Distribution Center in South Hackensack. “HYTORC has customers throughout the world that need its unique industrial bolting equipment,” said HYTORC President Eric P. Junkers. “Now, with this distribution center, HYTORC is able to ship…

Électricité de France completes validation testing of HYTORC Nut

HYTORC’s advanced fastener technology again proved its reliability following the successful completion of qualification trials at the l’Association nationale pour la formation professionnelle des adultes (AFPA) workshop near the Électricité de France (EDF) Flamanville nuclear power plants in Cherbourg, France. Testing was focused on the HYTORC Nut, in hopes of adding this advanced fastener to…

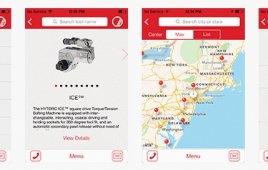

How much should I torque this bolt? HYTORC app tells

The Official HYTORC App gives users instant access to torque charts, safety and operational videos, product manuals, service center locations, and our comprehensive bolt load calculator. The calculator recommends the best torque values and bolt loads for a job as well the recommended bolting pattern based on the bolting system you are using and the…