Fluitec International says that Rob Hughes, Darin Carfaro, and Arturo Flores have joined the company to further develop their growing portfolio of regional and international accounts.

Working to make gearbox oil changes obsolete

Cristian Soto / Fluitec, Frank Magnotti / Fluitec, Greg Livingstone / Fluitec Not long ago, wind turbine maintenance was not considered an up-tower activity. Nacelles and their internal components were not designed for easy access or repair. They required excessive maintenance costs such as crane rentals. Fortunately, new nacelles are designed to be more up-tower friendly…

How does lubrication help a wind turbine?

Wind equipment requires specialized lubricants that are designed to last. Certain blends of base oil and additives cover the different lubrication requirements of individual bearings in wind turbines. A current trend has been finding ways to reduce maintenance costs and simplify lubrication routines. Also, as wind turbines are built higher and in more extreme conditions,…

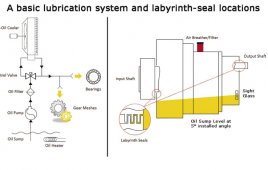

Two reasons why wind turbine gearboxes leak

Gearbox oil leaks present a special challenge in an outdoor green-power application. Unfortunately, they have been so prevalent, leaks are defined by their degree. Drips, leaks, seeps, and weeps all contribute to the costs of maintenance and to the environment in which we work, both in nacelle and out. The most common cause of gearbox…

Business group focuses on seals, lubes, and mold release

The Freudenberg Group says it has developed a range of product systems and services for the fast-growing American wind energy market. The product portfolio ranges from sealing product from Simrit, lubricants from Kluber Lubrication, and release agents from Chem-Trend. According to the American Wind Energy Association and Pike Research, the North American wind energy sector’s…

Trends in lubrication

Global lubricant demand is forecast to reach 40.5 million metric tons in 2012. According to a recent study, the market is estimated at $48.8 billion. Companies in this booming market are expanding their lubricant lines to include those for more industries such as wind. Wind equipment requires specialized lubricants. For instance, they may require certain…

Graco helps provide the right lubrication to the right bearing

A wide range of automatic lubrication products protect wind turbines while they operate. Accurate, reliable, and adjustable lubrication for each lube point keeps critical machinery in the nacelle running at peak performance for increased productivity, lower maintenance costs, and more efficient lubrication where and when it’s needed. Recent products from Graco Inc., Minneapolis, include several…

Automated lube lengthens life of bearings and seals

Maintenance crews acknowledge that frequent lubrications with small quantities extend the working life of bearings and seals. But long hours of hub crawling is physically and mentally demanding work. A better idea is a centralized and automatic lubrication system for wind turbines. One instance, the WindLub from SKF USA, Kulpsville, Pa., provides a cost-saving design…

Lubricants for equipment in the nacelle

Hydrotex formulates lubricants for wind turbines to extend drain intervals, provide maximum equipment protection, and maintain system cleanliness. Product recommendations from the Farmers Branch, Texas-based company can consolidate the number of different greases used, thereby reducing inventory and a risk of up-tower cross contamination. A few products for the wind industry include Gearox, an additive…