MRS Advances will reflect the way materials researchers work, write, publish, and share results.

Self-healing coatings, parts are next frontier for smart materials says Lux Research

Recent advances and ongoing improvements will help rapid and low-cost development of smart materials, and the next wave of innovation will be in self-healing coatings and parts, according to Lux Research. Smart materials – those that change their properties in response to environmental stimuli, providing dynamic capabilities — range from everyday items such as photochromic…

A new approach to blade repairs

By Louis C. Dorworth Division Manager-Direct Services Abaris Training Resources, Inc. As wind farms age and new turbines grow in height and blade size, the demand for maintenance and repair services is increasing at a rapid rate. Because of this, many new companies have emerged in recent years to meet the demands of wind farm…

Advanced materials set to trigger cost reductions in renewable energy

Philip Totaro, Founder & CEO, Totaro & Associates As the renewable-energy industry contemplates the future of technology, we have long contended that materials science will have the greatest impact on forthcoming cost reductions. With significant investments being made in R&D, we see a few classes of materials which deserve special attention, and potentially some additional…

Morgan Advanced’s carbon brushes lower maintenance costs and improve reliability

Morgan Advanced Materials’ range of carbon brushes are ideal for wind turbine applications, with new designs and materials that are resulting in longer brush life and increased generator uptime. Morgan’s globally available brush grades are created to be environment-specific, offering maximized performance in low or high-load conditions. Leading-edge laboratory equipment, coupled with years of experience…

Molycorp chosen to supply rare earths for use in high-efficiency Siemens wind turbine generators

Siemens AG has selected Molycorp, Inc. to supply rare earth materials over the next 10 years from its Mountain Pass, California facility for incorporation into Siemens’ high-efficiency, direct-drive wind turbine generators. Molycorp will supply rare earth materials to Shin-Etsu Chemical Co., which will produce the rare earth magnets Siemens intends to utilize in its wind…

Advanced materials improve cable performance

BICC Brand EmPowr Link+ TRXLPE insulated MV cable combines General Cable’s conductor and insulation shields with enhanced DOW Endurance HFDC-4202 EC next-generation insulation compound. Through advanced materials and processing capabilities –such as Class 10,000 material handling, 100% optical inspection, and true triple extrusion — EmPowr Link+ offers an improved dielectric performance and water tree retardance,…

Redox shuttle provides highest overcharge protection for certain cathodes

Scientists at the U.S. Department of Energy’s (DOE) Argonne National Laboratory have patented an extremely stable, 4-Volt redox shuttle molecule that provides overcharge protection for lithium-ion batteries containing lithium–iron-phosphate based cathodes across hundreds of charging cycles. Overcharge is a major safety concern for Li-ion batteries because it could cause thermal runaway, a concern for…

What Works in Aerospace Can Work in Wind

What do the areospace and wind industries have in common? They both depend on high-performance steel. Illinois-based QuesTek Innovations LLC (www.questek.com) has developed two types of gear steels that are already commercially available and in use in aerospace applications, but are suitable for wind-turbine gearboxes as well. Ferrium C61 and C64 are high-performance, double-vacuum-melted steels…

How are wind turbine materials changing?

One recent composite material provides a way to treat and modify the surface of fiberglass to create a chemical bond between the glass and a resin matrix. This material substitutes standard fiberglass with short micro-fibers. The manufacturer says its liquid composites can be poured, pumped, or sprayed, and after curing can be drilled, tapped, and…

Spanish turbine OEM opens materials tech center in Singapore

A Spain-based wind turbine OEM has opened a technology centre in Singapore to focus on advanced materials research. Gamesa’s new laboratory begins its work with three important research projects, conducted jointly with the Nanyang Technological University, the National University of Singapore, and the Agency for Science, Technology and Research (A*STAR). Gamesa expects the tech lab…

Blade-repair materials widen repair’s weather window

A novel approach to blade repair addresses several issues that have prevented more effective and expedient maintenance programs. The Renuvo blade-repair system is said to provide a solution to problems of production, transportation, and in-field work. Creating a wider weather window for repair work comes from a handling and working-temperature range that starts at +5°C.…

Composites One and 3M Renewable Energy Division Form Alliance

Arlington Heights, IL – Composites One announced that it has formed an important alliance with the 3M’s Renewable Energy Division. This agreement will allow Composites One and 3M to continue to penetrate the emerging wind energy industry with products geared specifically toward wind turbine manufacturers. It will also further enhance the partnership Composites One already…

Industrial “kitchen” Cooks up New Materials

Industrial designers and engineers face the challenge of new applications that require paying attention to material’s weight, strength, and cost. The rapid development of alternative energy and other industrial markets is driving a new demand for technology creators to construct and design these applications. So, a recently formed group at Cytec Engineered Materials, Tempe, Ariz.,…

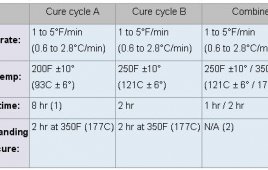

A material for large parts, without an autoclave

Cycom 5320 is a toughened epoxy resin prepreg system from Cytec Engineered Materials, Woodland Park, NJ. It is intended for out-of-autoclave (OOA) manufacturing yet provides the performance of an autoclaved material with the benefit of lower processing costs and manufacturing flexibility. The material allows designing large primary structures, without the costs and size limitations of…