The trend toward longer turbine blades means greater energy capture at lower wind speeds. However, with bigger blades comes increased weight and stress on the adhesive bond line. Polyurethane adhesives can improve the long-term performance of future blades while reducing total manufacturing cost. To boost energy yield, rotor blades are becoming larger and heavier. The…

What to consider in a contract

OEMs, such as Suzlon, have a contracts department to handle their many details. “You want to form relationships with carriers,” says the company’s Logistics Director Gary Kowaleski. One route to a good relationship is with a contract that leaves little to no interpretation. He suggests at least these items for a shipping contract: • Description…

When is a barge faster than a truck?

Not long ago, transport company ATS International (ATSI) was contracted to ship 100 complete wind turbines. Nacelles and hubs came from Germany, towers were made in Korea, and blades were transported from a fabrication facility in Little Rock, Arkansas. The units were allocated to multiple projects in the Pacific Northwest. Due to permit and financing…

Two cranes are better than one

The Port of Vancouver, Washington boasts two of the largest harbor cranes in North America. Each has a 140-metric ton capacity. The size allows reaching across a wide ship to unload heavy cargo. A 100-ton crane could have trouble unloading a Panamax-sized (wide) vessel because it cannot reach across the ship and pick up an…

Three ways to improve performance and reliability

There are three methods for monitoring wind-turbine operations: wind-conditions monitoring, performance monitoring, and condition monitoring. The terms are thrown around so much that many in the industry are confused. Although the terms describe different tasks, they have the same goal: performance and reliability of the wind assets. An automotive analogy may be useful. For instance,…

What’s community wind got over those mega farms?

Community wind refers to 100-kW to 100-MW projects owned in part by local community members, often land owners of the site. Though community wind represents only 4% of the overall wind market, it’s the fastest growing segment of the industry. The community-wind development model has several benefits over traditional absentee-owned mega farms. Landowners often have…

Shock-absorbing lanyards can let you down

A quick-acting braking system that arrests falls within inches, not feet, has safety managers retiring conventional shock-absorbing lanyards. Instead, they favor compact, lightweight, personal fall limiters (PFLs), also known as self-retracting lifelines. As manufacturers introduce PFLs with 100% tie-off fall protection (dual or twin legs), workers can move safely anywhere on a job site without…

Clever bolt tells when it’s tensioned

The wind industry recognizes the importance of proper bolt tension. The acknowledgement will challenge some of the industry’s torque-tightening practices as it matures and adopts more sophisticated technology to improve reliability and reduce maintenance costs. To start, let’s review current practices. For instance, bolts on turbines are often tightened in one of two ways: either…

Lowering O&M costs in the Lone Star state

While the wind-swept ridge tops of the West Texas plains are ideal for generating wind power, harsh site conditions can degrade turbine blades due to erosion from dirt, hail, lightning strikes, insects, and other airborne particles. Plus, fatigue from the sun’s UV rays and other natural elements leave hairline cracks and gouges in the leading…

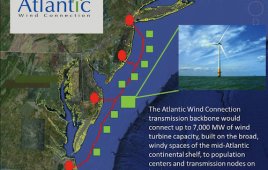

Major Transmission Project Planned for the Atlantic Coast

Google doesn’t mess around when it comes to investments. Their sponsorship in a transmission project that could cost billions of dollars stands as a major voucher for the wind industry. One of the greatest hurdles to the renewable-energy industry’s growth is the nation’s outdated transmission system. Without a beefed-up transmission backbone, offshore wind developers would…

The Right Turbine and Placement Produces 10x Power Increase

The power output of a wind farm of vertical-axis designs can be increased about tenfold simply by placing the turbines so they react with each other, say researchers at the California Institute of Technology led by John Dabiri, Caltech professor of aeronautics and bioengineering. In the summer of 2010, they conducted a field study at…

Bearing Manufacturer Unveils Plans for U.S. Wind Energy R&D Center

Massive, precision-engineered bearings and seals like those made by The Timken Company are central to wind power production. The largest of these rolling element bearings weighs more than five tons, with an ID of nearly 2 m. Such large bearings require sophisticated measuring and testing capabilities that replicate dynamic wind forces. For that purpose, Timken…

Turbine Doctors Revive a ‘Dead’ Vestas

It took two engineers from Availon North America a matter of hours to repair and bring on-line a Vestas V27 225-kW wind turbine that belongs to the Story County Medical Center in Nevada, Iowa. The turbine was commissioned at the end of 1994 but stopped working in April 2011 when the power supply for the…

New thinking in turbine design

A novel turbine design uses two rotors of equal diameter, one each at opposite ends of a nacelle, to capture wind at greater capacity factors than conventional designs can do, say developer Airgenesis LLC (airgenesiswind.com). The developer says the rotors, offset from each other by 60°, will be turning at low speeds of 2.5 to…

Entrepreneur Proposes Wind-Turbine Gear Factory For Indiana

You might think the U.S. has lots of gear-making capacity, so why would a start-up envision a factory capable of more of the same? The answer lies in the size of the gears planned by Vela Gear Systems CEO Noel Davis. Gears required in the wind industry can be in excess of 6 ft in…

Jack-up Vessels to Speed Offshore Wind Installations

The future of the world’s energy supplies is being decided to no small degree by offshore projects. Wind power offers its greatest potential at offshore facilities far from shipping routes and harbors. According to the European Wind Association, installed offshore output should increase tenfold in the next six years, reaching up to 15 GW. AWEA…

We’re in Campaign Mode Too

You have to admit that Congress has a lot on its plate right now with three wars and an economic mess, so expecting it to pass a national energy policy is a bit much. However, defining and financing such an enormous project should be the centerpiece of the next administration. At this time, both sides…

Life in The Supply Chain

McSwain Manufacturing, a division of Heraux Devtek in Cincinnati, Ohio, has been manufacturing power-generation parts for almost 30 years. In fact, it manufactured for GE Energy Power Systems even before the company purchased Enron’s wind division and entered the renewable energy industry. “Because they knew us as a trustworthy vendor, they approached us with a…

Linking into wind’s supply chain

Here’s the state of the wind industry in two paragraphs: Construction is shifting from the Midwest to states with Renewable Electricity Standards. There is a big push is to get costs out. OEMs prefer lean manufacturing principles to slice costs from components. Turbine OEMs have cut costs by about 25% over the past decade and…

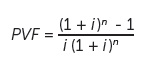

Improving a Project’s Rate of Return

When the Department of Energy enacted the national efficiency standard for distribution-class transformers up to 2,500 kVA in 2010 (72 CFR 58190), it excluded Generator Step-Up (GSU) units. This was unfortunate because the industry continues to construct wind-collector networks with sub-optimal GSU transformers which lead to lower overall collector efficiencies, lower kWh sales, and longer…