Today’s wind farm construction calls for an expensive and costly crane with a 100m reach or more to erect the towers and then lift the heavy nacelles, hubs, and blades to the top. But if the tower could do the heavy lifting, a shorter, conventional, and less expensive crane could be used and take big bite out of project costs.

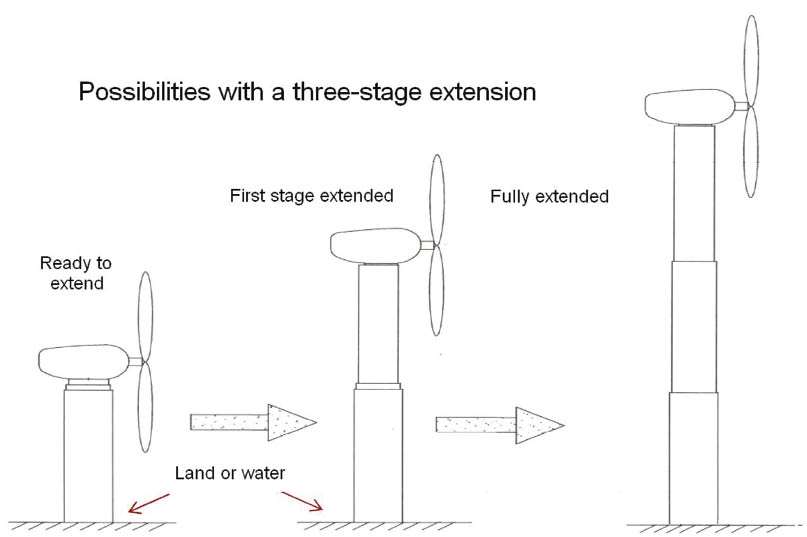

Inventor and professional engineer Phillip M. Schmidt, president of Schmidt Equipment Inc, thinks his telescoping wind tower idea can lower wind-farm construction costs by up to $200,000 per turbine, and bring a range of advantages to the wind farm operations and maintenance. Power for the tower extension will be provided by compressed air and expandable seals. Schmidt says that 45 psi on a 14-ft. diameter tower is sufficient to lift 445 tons. He points out that the Grove Co.’s GTK1100 telescoping tower crane is somewhat similar in operation in that its main mast is a round telescoping structure about the same height as a turbine tower.

The lifting tower would eliminate need for the 100-m crane by allowing installation of the nacelle, hub, and blades before the tower extends, so the components are lifted only one third as high as on a conventional tower. This makes it possible to use the smaller crane.

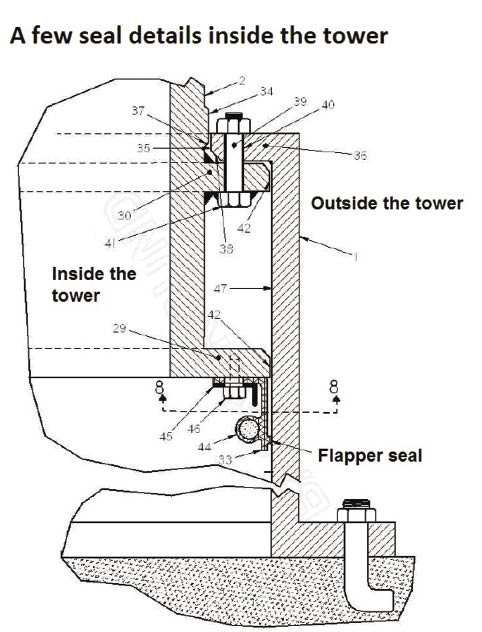

A tower segment reveals a few details around the seal section. Schmidt suggests using a flapper seal (33, 33a, and 44). The second flange (30) is for greater stability against tipping.

Another plus: Large turbines can be elevated to greater heights than possible when a giant crane is used. Turbine height is limited to the crane capacity. However, the economy of scale suggests operating as large as possible a turbine operating at as high as possible for lowest overall costs. What’s more, turbines could be erected on difficult or rough, but wind-rich, terrain that precludes the use of giant cranes.

In offshore work, turbines could work at greater heights than now possible and then be lowered closer to sea level when severe weather threatens.

Lowering a turbine for maintenance work would also reduce offshore costs. A tall barge-mounted crane adds considerable expense to an offshore wind farm.

Schmidt says the lifting capacity of a fluid (air) actuated telescoping tower increases rapidly as the tower diameter increases. This physics is advantageous to larger and heavier turbines likely to launch offshore.

Lastly, he adds, the telescoping tower could also function as part of a hybrid installation that could allows elevating large onshore turbines an extra 90 to 100-m by mounting the tower on a tall concrete base. Such an approach would not require the lifting tower to be made any thicker or any larger in diameter than today’s conventional towers.

Regarding tower internals, the inventor says the components typically installed in a wind tower can all be designed with relatively minimal changes so they fit and function within a fluid-actuated tower. Instead of attaching to the tower walls, cabinets, air conditioning elements, and walkways can be attached to a centrally located frame with the walkways folding down into place. Ladders can telescope and work platforms can either be eliminated due to unique nut and bolt configuration, or hang along with the power cables inside the upper tower section and then lowered and secured after extending the tower. The inventor says he’s forming a company to create capital to fund further research and development work, and that he’ll soon build a 10-ft. dia. x 10-ft high mock-up. A larger, taller version will follow late next year. WPE&D

Filed Under: Construction, Featured, News, Towers

This is a great idea. It may also have value in reducing component sizes, so transportation to sites is easier.

By contrast, having to use a great big crane to do the work, in windy places has to make construction a lot more specialist, expensive and dangerous. In waiting for good days, I’d imagine lots of dead time on really expensive crane hire.

Short times to bring up generation and realize income are a key advantage of wind. Telescoping towers could spring wind farms a lot quicker!!

Great concept, but we did this about 14 years ago in California (Tehachapi). The concept works for smaller turbines but adds significant cost. The problem with making towers taller is not the installation of them or the maintenance of the turbine afterwards, it is making the tower base wide enough to handle the increased load.

Go see a real turbine and try to draw it again but this time with (correct) scale while drawing…you will be amazed

the technology is already available. We in the tower crane and as the article confirms hyd. crane industry do this every day.

the ability to build close to the ground is preferable for many reasons. I would also incorporate the folding idea used in the aircraft industry to accommodate the 3rd blade.

I would be interested in working with any one with similar aspirations.

WM. L S

Maybe it’s just me, but isn’t there a pretty big scale error on the drawing? The blades are far too small:

http://commons.wikimedia.org/wiki/File:Off-shore_Wind_Farm_Turbine.jpg