The recently drafted ISO/IEC standard for wind-turbine gearboxes is significant for many reasons. First, several organizations collaborated to produce ANSI/AGMA/AWEA 6006-A03, which was adopted without change in 2005 as ISO 81400-4, an international standard. The new draft (IEC project 61400-4), expands on preceding standards so it is more encompassing. It provides a conduit through which manufacturers and users can specify and evaluate products. The new IEC standard is a bit overdue, but may have been worthy of the wait.

The present ISO standard’s introduction briefly tells why it was developed. It says, for instance, the operation and loading of a wind turbine, speed-increasing gearbox is unlike most other gear applications so the intent of the standard is to describe the differences. AGMA standards have relied heavily on the experience of gear system performance in related applica-tions, whereas other standards are based on theoretical and laboratory data. But much of the information in 6006-A03 is based on field experience. The standard is a tool that lets wind turbine and gearbox manufacturers understand each other’s needs in developing a gearbox specification for wind turbines. The annexes also include informative discussions of various wind turbine and gear design applications.

The committee responsible for ANSI/ AGMA/AWEA 6006-A03 was somewhat unique in that it was composed of wind-turbine manufacturers, users, researchers, consultants, gear and bearing manufacturers, along with lubricant and system suppliers from around the world who brought years of experience to meetings.

The range of disciplines was needed because a wind turbine is one of the most demanding applications for a gearbox. It requires a relatively small, compact, high-power-density gear drive and an electric generator to transmit fluctuating loads in a harsh environment of deflections, high vibration, and temperature extremes.

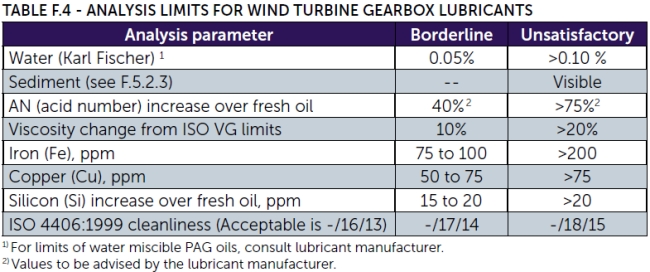

The table on limits to lubrication contaminants is one example of information found in ISO 81400- 4 (ANSI/AGMA/AWEA 6006--A03), Annex F “Lubrication selection and condition monitoring”. Source: ANSI/AGMA/AWEA 6006-A03

The present ISO standard applies to gearboxes with power capacities from 40kW to about 2MW. I say “about” because 2MW was a sort of sweet spot for OEMs at the time of the standard’s development. Technology, of course, marches on and larger units are on drawing boards and in production. So the standard is a snap shot in time of sorts. The new version addresses larger units and other concerns.

Still, the standard generally applies to parallel axis, one-stage epicyclic, and combinations of epicyclic and parallel-shaft designs. It provides requirements on specifying, designing, manufacturing, operating and monitoring reliable wind-turbine gearboxes. Designers should be interested in the more comprehensive application sections, such as:

• How to specify system loads and calculate gear capacity. Turbines require special attention because their gearboxes have to be relatively light weight. They will operate in tall towers so every pound must be considered.

• Manufacturing, inspection, testing, and documentation requirements were rewritten to include items that are intended to achieve the reliability required of wind turbines.

• Advanced gear-tooth-contact analysis and verification received attention because it has been shown that the prediction of torsional and lateral deflections in a high-power gearbox is important to proper operation.

• Extensive information on the application and capacity of rollingelement bearings were deemed necessary because the service operation of some bearings are troublesome.

• Lubricant and lubrication equipment receive attention because the characteristics of a lubricant and its distribution can make or break a highpower-density gearbox.

In addition, annexes supply information on wind turbine architecture, load descriptions, quality assurance, maintenance, lubrication selections, condition monitoring, and minimum ordering information from purchaser to gearbox manufacturer.

A few other additions and modifications include sections on design life and reliability, design process, wind-turbine-load calculations, gearbox components, design verification validation, operation, service, and maintenance requirements.

It is hard to determine what will be retained after the three required ISO/IEC ballots complete in about three years. In the meantime, most engineers believe the ISO/IEC standard has improved gear reliability. Bearings, however, still seem to need additional work.

Lastly, even though developing standards is a consensus process, individual positions have been expressed that enhance the document. The content of these standards may provide other ideas for designers in many gearbox applications.

Filed Under: Components, Gearboxes, Turbines