Editor’s Note: The following was authored by Hansen Hunt and was posted at the Upwind Solutions blog site here http://goo.gl/cDIHBI. It references a case study here: http://goo.gl/wnpRRZ

An improvement of just one ISO code in oil cleanliness can extend the bearing’s “relative life” by 20%. Three code drops can provide a 70% life extension.

Clean oil from day one maximizes the life of the gearbox components and provides the greatest cost savings if done at the time the turbine is commissioned. New technologies allow wind farm owner/operators to improve oil cleanliness in the wind turbine gearbox starting on the day it is commissioned. By implementing this reliability-centered maintenance approach from COD, owners can significantly lower maintenance cost and extended equipment life. That can add years of uninterrupted service and significant increases in return on their investment.

Owner/Operators of wind farms have struggled as maintenance costs have exceeded expectations. Projected life span for a wind turbine and specifically the gear box was 20 years. In some cases reality is less than half that. The costs of those early failures will have a negative impact on the business model of many wind farms.

Owner/Operators of wind farms have struggled as maintenance costs have exceeded expectations. Projected life span for a wind turbine and specifically the gear box was 20 years. In some cases reality is less than half that. The costs of those early failures will have a negative impact on the business model of many wind farms.

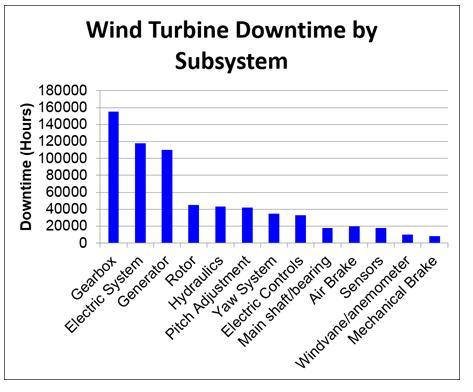

Identifying primary causes of turbine downtime

Prioritizing focus on the most costly failure mechanisms in wind turbines allows the greatest opportunity for improving the bottom line. In analyzing the failure rates of key components within the turbine, the report from the National Renewable Energy Lab, NREL/TP-5000-52748 states, “three elements that comprise the wind turbine drivetrain – the gearbox, generator, and main shaft/bearing – together cause the majority of the total turbine downtime.” Of those three elements, the leading contributor to total turbine downtime is the gearbox. By far, the leading cause of these gearbox failures is their bearings. According to Shawn Sheng of NREL, of 34 gearbox failures tested from four different OEMs, 72% of failures were from their bearings.

The ROI of clean gearbox oil

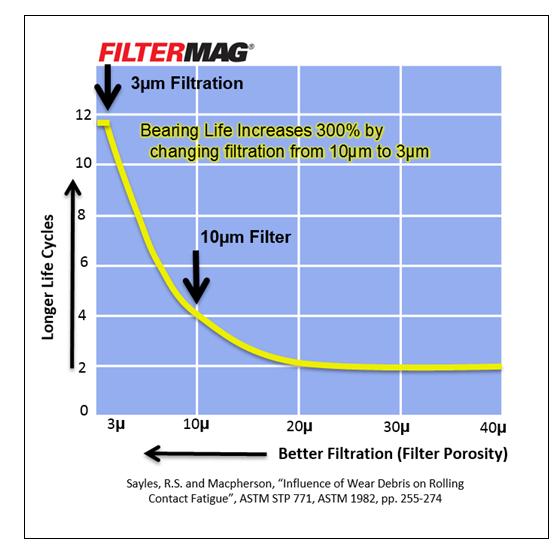

The Macpherson Curve highlights the importance of clean oil to the longevity of the roller bearings. Eliminating the smallest wear particles has the greatest effect on the reliability and life of the bearings. The majority of wind turbine gearboxes filter oil at 10 microns. The Macpherson Curve predicts that the life of the bearings will increase by ~2 to 3 times, if the oil can be filtered to 3 microns.

In addition to the Macpherson study, Noria combined years of data from many industries and applications to understand the impact of improving oil cleanliness on the life span of various components. Using the data from the Noria chart of Life Cycle Multipliers for Roller Bearings,an improvement of just one ISO code in oil cleanliness can extend the bearing’s “relative life” by 20%. Three code drops can provide a 70% life extension.

In addition to the Macpherson study, Noria combined years of data from many industries and applications to understand the impact of improving oil cleanliness on the life span of various components. Using the data from the Noria chart of Life Cycle Multipliers for Roller Bearings,an improvement of just one ISO code in oil cleanliness can extend the bearing’s “relative life” by 20%. Three code drops can provide a 70% life extension.

“Relative life” means the life extension is relative to the component’s remaining life at the point in time that the change in oil cleanliness occurs. Clean oil from day one maximizes the life of the gearbox components and provides the greatest cost savings over the life of the turbine.

Act now to improve gearbox reliability

Improving oil cleanliness in turbine gearboxes can be accomplished in different ways. One way is to change to a 5 micron main filter. This will help but requires more expensive filters that will need to be changed more often, to prevent them from going into bypass mode. A second way is to plumb in a “kidney loop” pump and filter system on the gearbox oil sump. This is also an effective means to cleaner oil but requires a significant cost upfront to purchase and install. It also adds an ongoing cost for a second filter as well as continued maintenance.

Download Case Study A newly introduced method to achieve cleaner oil is to add supplemental magnetic filtration to the main filter. This method is highly effective in removing ferrous particles (most gearbox particles) but will not take out other debris.

Filed Under: Filters, News, O&M