The power output of a wind farm of vertical-axis designs can be increased about tenfold simply by placing the turbines so they react with each other, say researchers at the California Institute of Technology led by John Dabiri, Caltech professor of aeronautics and bioengineering. In the summer of 2010, they conducted a field study at an experimental two-acre wind farm in northern Los Angeles County. VAWTs are ideal for this experiment, Dabiri says, because they can be positioned close to one another letting them capture nearly all of the energy of the wind and even wind energy above the farm. Having each turbine turn in the opposite direction of its neighbors increases their efficiency, the researchers found, possibly because the opposing spins decrease the drag on each turbine, allowing it to spin faster (Dabiri got the idea for using this type of constructive interference from his studies of schooling fish). A paper describing the results of field tests appears in the July issue of the Journal of Renewable and Sustainable Energy.

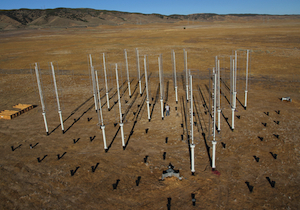

Dabiri’s recent experimental farm uses 24, 10-m tall, 1.2-m wide vertical-axis wind turbines. No results are available yet. The 2010 field tests used only six turbines.

Conventional wind farms use horizontal-axis turbines. But despite their improvements, says Dabiri, they are rather inefficient. Individual turbines in them are spaced far apart so the wake generated by one turbine does not interfere with those downwind. The result: “Much of the wind energy that enters a wind farm is never tapped,” says Dabiri.

Turbine designs have trended to larger units on taller towers to capture more of the available wind at heights where it is stronger and steadier. But this brings other challenges, such as higher costs and more complex engineering problems.

The solution, says Dabiri, is to focus on the design of the wind farm, to maximize its energy-collecting efficiency at heights closer to the ground. Winds may blow less energetically at 30 ft. rather than 100 ft., “But the global wind power available at 30 ft is greater than the world’s electricity usage, several times over,” he says. That suggests smaller, less expensive vertical axis turbines arranged in the right way can capture sufficient energy in a less environmentally intrusive manner.

During the summer 2010 field tests, Dabiri and colleagues measured rotational speed and power generated by each of six turbines when placed in a number of different configurations. Tests showed one arrangement in which spacing the turbines four rotor diameters apart nearly eliminated aerodynamic interference between neighboring units. The six VAWTs generated from 21 to 47 W/m2 of land. A comparably sized conventional farm generates just 2 to 3 W/m2.

In comparison, removing the aerodynamic interference between horizontal axis wind turbines required a spacing of about 20 diameters, more than a mile between the largest wind turbines now in use.

Counter-rotating vortecies generated by a swimming fish inspired Dabiri to consider a close arrangement of vertical axis wind turbines.

“The next steps are to scale up the field demonstration and improve on off-the-shelf wind turbines used for the pilot study,” says Dabiri. During the past summer, Dabiri and colleagues studied a larger array of 18 VAWTs to follow up last year’s field study.

WPE

Filed Under: Construction, Towers