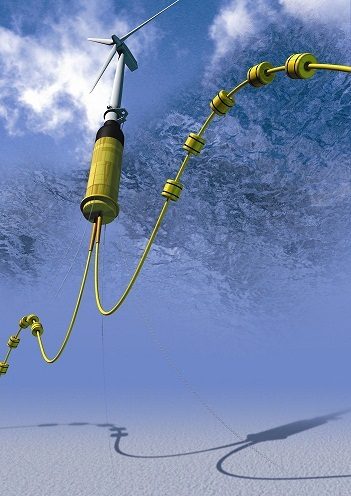

The cable is supported mid-water by Distributed Buoyancy Modules in what is known as a ‘Lazy Wave’ configuration. It features gentle large-radius curves that minimize stress on the cable while accommodating natural movement created by wind and waves.

The innovative offshore floating Hywind wind turbine, moored in the North Sea off the Norwegian coast, demonstrates how Trelleborg Offshore’s syntactic foam buoyes contributes to the future of offshore power generation. “People see the tower and turbine, but forget that the expertise in designing the subsea portion is also critical, because it keeps the whole turbine afloat,” says Gary Howland, the company’s Renewables Sales Manager. “The dynamic floating structure weighs 5,300 tons and measures 165-m tall. A full 65m floats above the sea surface. The 13 km power offtake and communications cabling attached to the structure further adds to its weight.

“This subsea technology is already proven. The Distributed Buoyancy Modules (DBMs) developed for deepwater support of umbilicals and risers in the oil and gas industry are ideal for this application becuause they help reduce project risk using proven technology.

“It’s like an iceberg; the mass floating below the surface ensures stability. Unless the weight is supported by properly designed buoyancy the whole structure would be much less able to resist the extremes of the offshore environment and the cable could suffer premature damage,” says Howland.

For Hywind, Trelleborg Offshore designed and supplied 45 polymer-coated syntactic foam DBMs which provide buoyancy support for a 3 ton, 100-m section of cable as it exits the turbine spar and descends to the sea bed at 220m below the surface. The buoyancy modules include an internal clamp for secure fastening and precise positioning on the cable.

“For best buoyancy under different sea conditions, engineers calculated the position of the buoyancy modules on the cable. The positions must be maintained, despite stresses during launch and in operation. The clamp is crucial. Its design, material selection, and manufacturing technique are critical ensuring the finished clamp maintains the buoyancy module position, during cable contraction and expansion, over the 20 year lifetime of the project.

“Trelleborg Offshore has substantial expertise operating in deep water and subsea environments, and a track record acknowledged by many offshore engineering companies. The company also has experience with DBMs and says more than 35,000 modules are in service.

“We have seen many of the technical challenges before, in the offshore oil & gas arena, so our engineers can quickly and easily adapt proven solutions for use in offshore wind-power generation. This will greatly reduce project risk and let industry develop quicker and at less cost.”

Filed Under: News, Towers

Very interesting article.

Any idea of the anticipated cost of building something like this? Just from looking at it it looks very expensive, which in my mind begs the question “Why bother?”. The name of the game is Cost of Energy, and the promise of “free energy” from wind, at an elevated initial cost might not make any sense, even if you can iron out all the inherent technical challenges.

How does the initial cost and the future maintenance costs of this system compare with land based?

The problem with this design is the weight is concentrated with a small footprint rather than spread out (i.e. buoyancy is depending on volume. Any grade school kid knows that.) That’s exactly why this design will encounter so many problems for say 5MW+ due to its weight. The floater will be so big and uses so much more metal. As the diameter of the bulb increases, it will be subject to more movements from under sea current effects.

Offshore and deep water is certainly a special problem. This first construction is a prototype and an experiment. It will keep its designers in class for a couple years.