Think that it’s possible to multi-task while working with a live circuit? Or that there’s nothing to fear about low voltage? Think again is the answer from experts at Fluke, a manufacturer of industrial test, measurement, and diagnostic equipment

Read Fluke’s full top 10 list of electrical safety mistakes here.

The company wants workers to be safe and recently released the top 10 electrical safety mistakes.

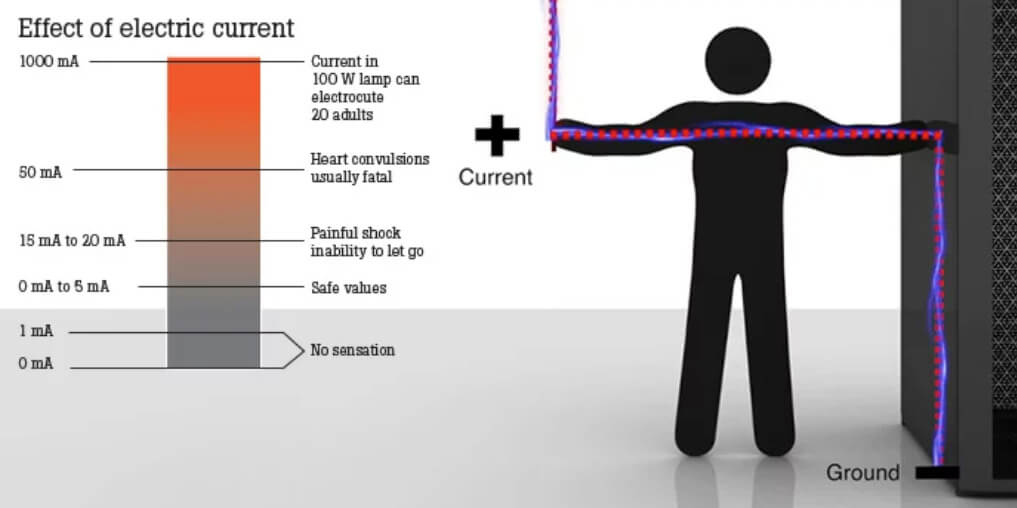

1. Underestimating the dangers of lower voltage levels

“It’s only 120 volts (or 208 or 480).” The only difference between low and high voltage is how fast it can kill you. High voltage kills instantly; low voltage may take a while longer. A 120 volt shock, for example, can lead to death up to 48 hours after the initial exposure. Take appropriate safety precautions.

2. Not wearing PPE during troubleshooting

Many people understandably don’t like wearing rubber insulating gloves or arc flash personal protection equipment (PPE), especially during troubleshooting. PPE can be hot, uncomfortable, restrictive, and slows the work process. But the reality is, component failure can happen at anytime. Whether from carbon build-up or eroded contact material, perfectly good breakers can fail suddenly during troubleshooting. Wearing PPE while simply opening a cabinet or making a quick measurement can mean the difference between injury and safety.

3. Using outdated or defective test equipment

Whether the leads are frayed or the readings seem strange, it could be time to replace dated test tools. Signs it’s time to let the old equipment go include:

- Unreadable faceplate

- Can’t get the same measurement from one time to the next

- Loose, cracked leads

- Not safety rated for your work environment

4. Not performing required maintenance of power system equipment

Too often companies look at maintenance costs as an overhead expense and don’t regularly inspect electrical distribution equipment. Although it might be difficult to quantify the savings attributed to preventive maintenance, real costs associated with broken down equipment include:

- Unscheduled down time.

- Loss of production.

- Overtime.

- Employee health and safety

5. Neglecting to properly inspect test instruments and leads

Before beginning the absence of voltage test, inspect the test instrument to ensure it is working properly. Inspection should include the following questions:

- Are they any obvious defects?

- Does the switch turn smoothly?

- Does the instrument have the correct CAT rating for the particular environment and equipment?

- Does the display function properly?

6.Using the wrong test tools for the job

- Make sure your test tool holds the correct CAT rating for each job you do, even if it means switching meters throughout the day.

- Don’t go for the cheapest tool on the rack. If that cheap test tool doesn’t actually have the safety features it advertised, you could end up a victim of a safety accident. Look for independent laboratory testing markings like CSA or UL.

Read the full list here.

Filed Under: News, Safety

Hey, you have shared very nice information.

You are absolutely right, Utilize a touch of wire or metal to get around the breaker all together. That may appear as though a convenient solution in case you’re gotten without an additional wire, yet that wire could be every one of that winds up among you and a spike traveled your direction.