Vickers screw-in cartridge valves provide advantages over traditional hydraulic valves. For example, screw-in cartridge valves are compact, reliable, and economical. In addition, combining multiple cartridge valves in a common manifold offers mobile and industrial users cost advantages unavailable in traditional valves.

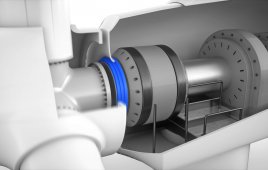

To provide smooth and consistent power outputs, wind-turbine manufacturers use hydraulics to set the “pitch” of the rotor blade. The Eaton Vickers KB range of proportional flow control valves from Eaton’s Hydraulics Operations, Eden Prairie, Minn., has been the frequently selected valve to control blade pitch. It is globally installed in over 20,000 turbines. KB proportional valves, along with power control electronics, allow accurate, high dynamic control of the blade pitch.

An amplifier is housed in a durable metal enclosure, sealed against environmental contaminates. The valves are reliable, rugged, and provide easy access for test equipment. The company says a few valve features include:

• An integrated amplifier for “plug and play” installation

• IP 65 & 67 environmental protection rating (best-in-class) for reliability to handle harsh environments

• Resistance to vibration and shock

• CanOpen bus communication option for easy diagnostics

• A complete size range, and

• Three performance levels: standard, high, and servo screw-in cartridge valves

Filed Under: Hydraulics