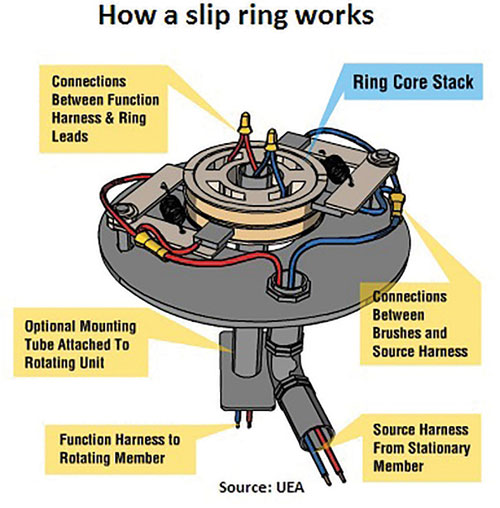

Slip rings provide a reliable transmission of power or signals from stationary cables in the nacelle to rotating equipment in the hub. A basic slip-ring assembly uses solid metal rings and graphite or precious-metal wire brushes, which contact the outside diameter of the rotating metal ring. As the ring turns, electrical current or signal conducts through the brush to the metal ring making the connection. Additional ring-brush assemblies are stacked along the rotating axis for more electrical circuits or channels.

Slip rings provide a reliable transmission of power or signals from stationary cables in the nacelle to rotating equipment in the hub. A basic slip-ring assembly uses solid metal rings and graphite or precious-metal wire brushes, which contact the outside diameter of the rotating metal ring. As the ring turns, electrical current or signal conducts through the brush to the metal ring making the connection. Additional ring-brush assemblies are stacked along the rotating axis for more electrical circuits or channels.

Several trends here are toward more reliable designs in new turbines and in replacement units. In the aftermarket, custom designs meet client specs, slip rings are available for non-supported machines, and combination devices for transmitting power, signals, and fluids. “New solutions are needed to replace older technology slip rings in turbines with long-life, high-reliability designs that can operate for years without maintenance,” says Moog’s Senior Business Development Manager Steve Black.

For pitch functions, the ideal slip rings would be installed and forgotten. Many designs in use today require periodic maintenance to clean away wear debris, flush out oil and dirt, and relubricate. In pitch slip rings, design trends are on at least two fronts. “First, as turbine designs increase in power output and size, the demand on the pitch slip ring is for higher power transfer,” says Black. “Second, data handling and signal demands are increasing to provide additional condition monitoring in the hub. It is critical that the contact technologies be durable enough to handle power peaks at the extremes of operation.” More complete pitch control is another trend. These would include hub controls, pitch-drive motors, power back-up, blade monitoring, and slip-ring channels to transfer the power and control signals through the rotary interface.

A quest for higher reliability has encouraged some companies to devise non-contacting slip rings. At least two companies are at work here developing inductively coupled power transfer devices. One manufacturer says its slip rings work at high efficiencies by using wireless power transfer that can harmonize itself in the field. The company says this makes the systems resistant to changes in environmental conditions and load variations. Power transmits as a single load while a built-in, data-communications system switches power, for example, to meet different device requirements of wireless receivers.

Collaboration is another trend. One ISO is partnering with a slip-ring manufacturer to design, manufacture, and distribute slip rings. Manufacturer UEA says it provides its slip rings as completed, ready-to-mount assemblies with optional pre-wired harnesses. The goal is to reduce up-tower time so the company makes a wide selection of circuitry available, with many combinations of amperage and voltage, ac or dc. The compact design is made possible by stacking brushes on alternating sides. The slip rings come in bore sizes from 0.500 to 14.00 in. UEA President Mark Hanawalt says his company’s custom-designed wind turbine slip rings match customers specs and can be delivered in a matter of weeks.

UEA recently designed an improved slip ring for Clipper wind turbines. It’s more reliable, says Hanawalt, with improved sealing, removing the exposed external wiring, and enhancing the communication circuits. For instance, a new ball bearing design significantly improves bearing life over the original design, which required more delicate handling.

Trending offshore — Manufacturer Deublin says its off-shore wind turbine union includes a slip ring and encoder. Units for off-shore and on can deliver up to 250A, transmit Ethernet and Profibus signals, resist shock and vibration, and provide a protection class IP 54-IP66. Add a rotary union and device accommodates hydraulics, electrical power, EtherCAT, and rotary position information. “Offshore turbines will require more reliable components due to their remote locations. Cost and time of reaching the offshore turbine is significant compared to most of the onshore turbines” says Jerry Lichter, Senior Product Engineer at Deublin.

Lastly, custom designs and combination units — Building blocks allows solving design challenges such as RF shielding, mixed signal handling, high-frequency-impedance matching, reduced temperature generation, and miniaturization, says Deublin. The company adds that its plug-and-play slip ring and union combination reduces installation and maintenance time because electrical and hydraulic connections are plugged or unplugged as part of the installation or removal process rather than having to disconnect those cable connections and hose fittings separately. Other options include absolute or incremental encoders, optical rotary joints for fiber optical connection, even an internal heater for use in cold weather.

Filed Under: Featured, Turbines

he company adds that its plug-and-play slip ring and union combination reduces installation and maintenance time because electrical and hydraulic connections are plugged or unplugged as part of the installation or removal process rather than having to disconnect those cable connections and hose fittings separately. Other options include absolute or incremental encoders, optical rotary joints for fiber optical connection, even an internal heater for use in cold weather.

ARS SLIP RING http://www.arslipring.com

it is very good ars slip rings