Editor’s note: Accio Energy recently released this commentary on their research.

Imagine if the wind turbine of the future is not a wind turbine at all, says Accio Energy.

A company spokesperson also asks: What if there is a better way to convert wind energy into electricity than three 150 foot blades going up to 180 mph while spinning around a 140 ton housing 250 feet in the air?

Accio Energy’s EHD says it has a wind energy system that generates electricity using wind and charged water mist. The wind separates positive and negative charges as it moves the charged water mist. The separation of charges creates high-voltage, direct current electricity. The generator itself has no moving parts and consists of wind-permeable flat panels composed primarily of easily mass-produced tubes. The panels can combine into arrays, easily scaling from kilowatts to gigawatts. Accio says its generator is modular, transportable, and cost effective.

The wind separates positive and negative charges as it moves the charged water mist. The separation of charges creates high-voltage, direct current electricity.

All power generation methods compete with each other on cost. A key advantage of Accio Energy’s approach is the potential to make offshore wind power cost-competitive without subsidies against natural gas, even at today’s historically low prices. Accio says wind energy can achieve the projected cost reductions because of two main advantages it has over conventional wind turbines:

- Lower manufacturing cost

- Higher capacity factor

Accio Energy says its wind systems will be cheaper to manufacture because of their modular, panelized design, with a similar energy density, size and form factor as solar panels. Accio systems, composed of common materials, can be manufactured using automotive manufacturing technologies and cost structure. A single company wind panel that is the height and length of a standard shipping container could produce 2.5 to 3 kW of rated power as part of a utility-scale array.

The company’s team includes manufacturing experts and former automotive OEM manufacturing executives. They estimate that a single manufacturing facility the size of an automotive assembly plant should be able to produce at least 4,000 such panels each day, resulting in 10 to 12 MW of wind generation capacity. This is equivalent to delivering four 3-MW wind turbines every day of the year from a single plant.

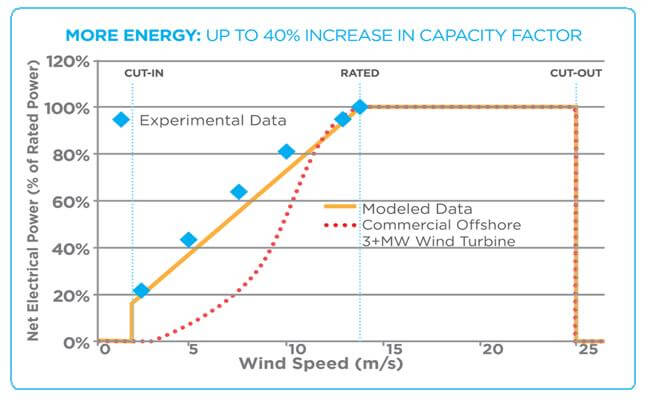

The company says its wind energy systems have up to a 40% higher capacity factor than wind turbines.

The company also says its wind energy systems have up to a 40% higher capacity factor than wind turbines. In traditional wind power, wind energy moves a mechanical structure with heavy rotating loads and a high fixed mass inertia. In Accio systems, wind energy couples to water droplets that move charge against an emergent electric field to produce electrical power. Accio wind systems have a variable inertia, because the number of droplets and the charge on the droplets can be quickly adjusted. As a result, Accio says its wind system can operate at peak efficiency at all wind speeds resulting in a power curve as shown, with a 40% increase in capacity factor, and the associated 40% increase in energy generation.

Filed Under: News, Turbines