As locations with higher wind speeds become saturated, the wind power industry has begun developing areas with lower, yet useful, wind. Turbine manufacturer Suzlon supports this idea and suggests its latest generation S9X 2.1-MW machine to meet the demand. The S9X, an evolution of the S88, operates on a wider wind-speed spectrum, while still improving on the performance of its S88 fleet. Available as an S95 or S97, both machines include larger rotor swept area, a doubly fed induction generator, and a variety of improved reliability and safety features.

Strong

While the S9X’s hallmark is its variable speed technology, the company’s design was developed with strong features and components based on lessons learned from more than 8,000 wind turbines Suzlon has installed globally. The S9X’s design starts with the current S88, which boasts 2,300-MW of installed capacity among 17 U.S. states in the U.S. It averages over 97% availability, making it Suzlon’s most robust turbine until now. Like with all their machines, Suzlon’s experienced team of technicians, engineers, and SCADA experts keep an eye on the turbines with 24/7 monitoring, which features the company’s Weather Sentry tool. This warns of inclement weather, gives pre-notice for specialized parts and tools, and allows better O&M scheduling.

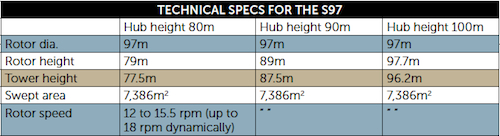

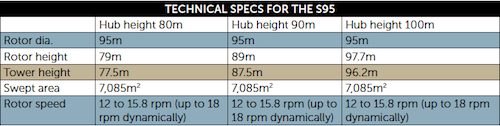

The S9X platform includes a range of options to improve return on investment. The turbine can be customized for temperatures down to -40°C and AC frequencies of 50 and 60 Hz. A variety of tower heights−15% lighter−are also available due to customer demand, including 80, 90, and 100-m hub heights to allow higher power generation in low to medium wind speeds.

Smart

A choice of two models helps harness wind in a variety of climates with large rotors of 95 or 97-m diameter. The S95 is well-suited for Class IIA sites with medium wind speeds, while the S97 is better for Class IIIA, low wind-speed areas. The S95 blade has optimized lift-to-drag performance, and features a double-shear web design to allow for a longer, thinner blade that maintains needed stiffness over its entire length. S9X blade material enables low weight and high structural reliability with their cores incorporating balsa wood and exacting use of high-strength fiberglass. The blade’s trailing-edge thickness was restricted to minimize bluntness noise, while tip geometry can reduce sound even further.

Suzlon also owns a blade testing facility that boasts GL certified static testing and its own dynamic testing that exceeds industry standards. Both blades have been tested to exceed the industry baseline by simulating total life cycle (1 million cycles) in the most extreme on-site conditions.

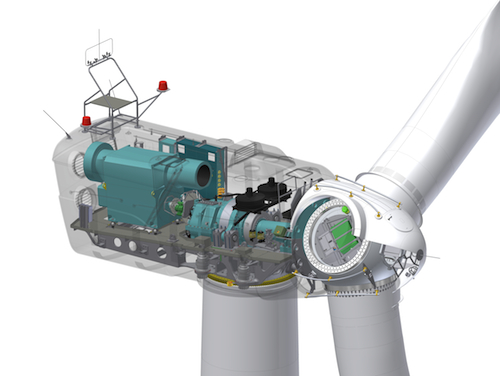

Power delivery is said to be improved with a Doubly Fed Induction Generator (DFIG), which is fully compliant around the world for today’s grid codes, as well as those being contemplated in all 50 and 60-Hz markets. The S9X uses fewer moving parts than the S88 flexi-slip system and hosts an induction generator.

In addition to better grid compliance, Suzlon says the S9X’s pitch and yaw systems add to the overall stability with component standardization. This allows reducing the number and costs of stored units, making delivery times faster and minimizing down time. An additional fourth yaw drive with better yawing control improves balancing and load sharing, making the turbine more stable. Corrosion protection has also been improved for increased lifespan, which goes a long way in harsh climates.

Upgraded pitch-drive software (Pitch Master II) improves control and operations to precisely drive the blade to optimum position. Suzlon says its software has been in field tests since 2010 and has sustained 100% availability. Furthermore, the battery box features low-temperature conditioning and easy to service battery trays (5 battery trays containing 6 batteries each).

Upgraded pitch-drive software (Pitch Master II) improves control and operations to precisely drive the blade to optimum position. Suzlon says its software has been in field tests since 2010 and has sustained 100% availability. Furthermore, the battery box features low-temperature conditioning and easy to service battery trays (5 battery trays containing 6 batteries each).

Cable guiding in the S9X focuses on serviceability by securing cables to the nacelle, thereby avoiding bends and controlling movement. This cable routing eliminates sharp bends with defined placement of cables to help address mechanical friction or potential loss of insulation.

Safe

The S9X includes enhanced safety features that aim to make maintenance easier and more cost-effective. First off, it has IEC Class I lightning protection, which is in accordance with IEC Class I standards to ensure the highest protection. Strategic nacelle access doors and an extended beam crane aid in lowering components to the ground for easier maintenance, material handling, and the option of emergency rescue should the need arise. An internal long-bended crane rail system makes for convenient handling of parts inside the nacelle. Safety rails and strategic eye placement on the nacelle allow enhanced tie-off and maneuverability through a fall-arrest-rated railing and anti-skid surfaces

The company says OSHA positively reviewed the nacelle’s rotor-lock system, which features both a hydraulic lock and mechanical lock using two different forms of energy for a fail-safe mechanism. A manual locking provision provides secure “lock out, tag out” interface. The hub structure adds additional safety with a hinged door and safe locking system at 90°.

The company says OSHA positively reviewed the nacelle’s rotor-lock system, which features both a hydraulic lock and mechanical lock using two different forms of energy for a fail-safe mechanism. A manual locking provision provides secure “lock out, tag out” interface. The hub structure adds additional safety with a hinged door and safe locking system at 90°.

In the tower, a climb-assist system reduces stress-related injuries and assures safe maneuverability of technicians. Suzlon has also published a comprehensive safety guidebook to cover S9X safe operation and control.

The company expects Germanischer Lloyd will certify all S9X machines in standard temperature, while regional and country-specific certifications will also be available.

WPE

Filed Under: Construction, Towers