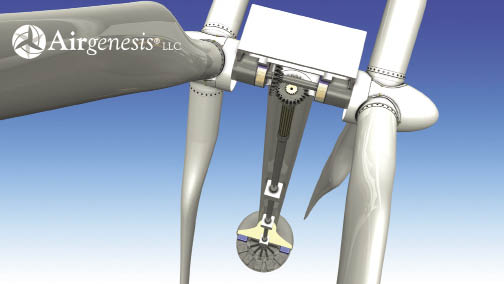

The Airgenesis uses two 100-m diameter rotors turning in the same direction and mounted on a 76-m tall tower with a 10.3-m diameter base. Planetary gear sets increase the rotor speed (15 to 20.6 rpm max) and a right-angle drive will send power down-tower by a steel shaft at 240 to 258 rpm max. Twelve generators at the base will come online as wind permits. The blue boxes are 500-kW generators and the others, 1 MW units.

About a year ago this magazine reported on the design completion for a twin-rotor turbine that its developer boasted was capable of generating 11 MW. The Airgenesis turbine (airgenesiswind.com) sports other innovations, such as using a shaft to transmit power down tower to several generators arranged in a circle at the tower base. Twelve generators, two 500 kW units and 10 rated for 1 MW each, will let the turbine begin generating power in usually unproductive 3 m/s winds. Airgenesis spokesman Clayton Troxell recently provided an update on the project.

“We’ve making good progress in that we’ve completed more testing on the digital prototype by aerospace engineering firm DARcorporation,” says Troxell. “From their simulations, we found that best clock angle for the blades is a 30° separation, not 60°. It turns out that 30° lets the wake from the front rotor more often miss the aft rotor, allowing a 92% yield.” The company originally thought that low rpms would be good for the aft rotor, but simulations showed that increasing the rotor speed to about 15 to 20.6 rpm achieves a higher electrical production and at the same time reduces the torque on the entire drive train, and in turn, reduces the size of the gearing.

Troxell says DARcorp. conducted about two weeks of tests on its supercomputer to confirm previous expectations and explore other possibilities. For instance, it found that output could be bumped to 16 MW if they used blades larger than the planned 48-m blade detailed by the NREL/NWTC Informational Portal.

“We are aiming for lower wind speeds because a variable speed 500-kW generator at the base begins producing power in lower winds. The power curves produced by Darcorp. show power production starting at 4 m/s because that’s when 15 rpm on the blades is possible. Also, the design should handle winds that would shut down conventional turbines. For the time being, we will say 11 MW is tops,” Troxell adds.

He also says the design is headed to prototyping. It will take a year to build the 11-MW prototype and Airgenesis expects it to fly in 2014. “All manufacturers are in line and the tower guys are ready to go,” he says. WPE

Filed Under: News, Turbines

Wonderful concept. I saw the twin rotor system with 3 blades each in Wave Turbine. Seems that will work with with Wind Turbine as well.

So just 90 turbines of these could provide 1,000 MW, the capacity of large power plant. My appreciation to those scientists / engineers.

As the pioneer of dual-rotor turbines

http://www/dualrotor.com

my opinion is that the rotors are too close together for the second rotor to add power, assuming the first rotor is efficient.

The advantage of a second rotor is NOT achieved by “clock-indexing” the second rotor to the first. This simply repeats the classic beginner mistake of trying to “rescue all that lost energy leaking between the blades”. If a rotor is properly designed, there is no energy “leaking through” the rotor, and if there were, it could be captured by adding more blades to the first rotor, instead of trying to “clock” the “leaks” to be “rescued” by a second rotor. Also, placing the generator(s) at the base of the tower is another classic beginner “solution in search of a problem” which has been suggested many, many, many times over the decades but never borne fruit. The way a dual-rotor wind turbine can capture more energy is to separate the rotors sufficiently that with an offset aim, the second rotor is placed into its own fresh wind flow, largely undisturbed by the first rotor. This increases swept area without increasing diameter. Two rotors is just a toe-in-the water: an almost unlimited number of rotors can be combined using this technique, with no firm upper power limitation to a multi-rotor machine that can have as few as a single moving part. A 10-foot-diameter dual-rotor turbine that has been tested for years and will not burn out at any windspeed is available today. It’s all patented around the world and a U.S. Trademark has been issued for the “SuperTurbine(R) multi-rotor concept. Somehow it did not appear in this article, nor do I imagine it is in the current article on “7 new types of small wind turbines” which I saw a headline for but could not find the article.(?) All in all I’d place this “press-release breakthrough” in the same category as “Whalebumps”: good luck with that… As far as breakthrough small turbines, the market leader just went bankrupt because all their models had insufficient overspeed protection and burned out or broke too often, burying the company endless in warranty returns. The latest SuperTwin(TM) model at http://www.dualrotor.com has not burned out in a generator in the latest year of testing, through several newsmaking windstorms, at our most punishing test sites.

Thanks

🙂

Doug Selsam

http://www.dualrotor.com