SKF is launching the first of a new generation of shaft alignment tools. The new TKSA 11 is said to be the only instrument of its type featuring inductive proximity sensors, and an innovative, easy to use app for smartphones or tablets. This makes the TKSA 11 an ideal entry-level tool for maintenance or production engineers to carry out shaft alignment quickly, simply, and accurately for motor, fan, pump and compressor applications amongst many others.

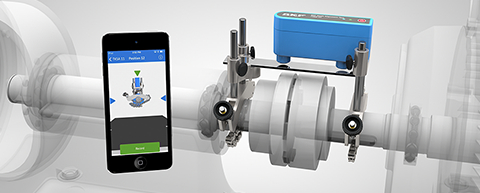

The measuring unit connects to an iOS smartphone or tablet via Bluetooth, with the app exploiting the computing and display performance of the mobile device to provide an intuitive alignment process using live view and animations.

It is estimated that misaligned shafts can cause up to 50% of all machine failures, affecting the reliability of bearings, seals couplings and belts. Additionally, incorrect alignment adversely affects energy consumption.

Shaft alignment has traditionally been carried out using laser tools, dial gauges or simply by line of sight and a straight edge. Laser tools can be expensive, whilst dial indicators are accurate but difficult to use and line of sight methods are inaccurate. Conversely, the SKF TKSA 11 enables quick, accurate and reliable shaft alignment that suits most budgets and is ideal for small to medium sized applications.

The TKSA 11 incorporates two inductive proximity sensors within a compact and durable electronic measuring unit, which is attached to the moveable machine side, on shafts or coupling sleeves, with a reference bar being attached to the fixed machine side. With an easy to use app, the user is guided through the measurement and correction of shaft misalignment, while a live view of the measuring unit and horizontal machine position facilitates accurate alignment.

The new measurement technology allows using TKSA 11 in bright sunlight and enables constantly high measurement accuracy regardless of the distances between the mounting brackets. This makes it ideal for aligning narrow couplings or for use in confined spaces. Optional extension rods and extension chains are also available to use with large couplings and shafts, further extending the application range of the TKSA 11.

The measuring unit connects to an iOS smartphone or tablet via Bluetooth, with the app exploiting the computing and display performance of the mobile device to provide an intuitive alignment process using live view and animations. The easy-to-use interface, with clear on-screen instructions, helps users shorten alignments tasks and provides a final report, with the option of a signature and picture.

The use of proven inductive proximity sensors, combined with a mobile app, eliminates the need for a built-in display on the alignment system, letting SKF introduce the TSKA 11 at a cost about half that of competing devices. The low cost and simplicity, accuracy and repeatability of the new instrument, means that for the first time precision shaft alignment technology is available to a wider audience than has previously been possible. This lets companies benefit from improved uptime, lower maintenance costs, and greater productivity.

SKF

www.skfusa.com

Filed Under: News, O&M