The stainless steel clam-shell cover improves the sealing in comparison to the cylindrical sleeve design. This new design also allows removing the cover for inspection or maintenance while keeping oil and other harmful elements out of the slip ring.

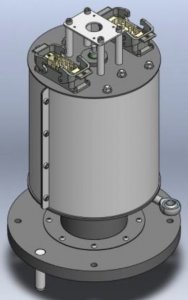

UEA has recently designed a new and improved slip ring for the aftermarket Clipper wind turbine. The new design has many improvements that make it more reliable, improve the sealing, remove the external wiring exposure, and enhance the communication circuits.

With unknown and varying vibrations from turbine to turbine, as well as the rugged handling which the slip rings are exposed to, the new ball bearing design significantly improves the life of the bearings over the original design.

The stainless steel clamshell cover improves the sealing in comparison to the cylindrical sleeve design. This new design also allows removing the cover for inspection or maintenance while keeping oil and other harmful elements out of the slip ring.

The original slip ring had external conduit with wiring to connection points on the upper harness. The new design eliminates the external harness conduits, integrates the new upper harness connection points into the top plate of the enclosure, and eliminates bulky exposed parts that were often damaged in handling during installation.

Due to the harsh and sometimes unknown environments within wind turbines, the communication circuits have been enhanced to improve their reliability. Silver graphite brushes now ride on coin-silver rings that are more resistant to corrosion. This results in more reliable communication.

UEA

www.uea-inc.com

Filed Under: News

It is a wonderful improve, also get more information from http://www.arslipring.com

http://www.moflon.com

moflon slip ring is high reliability slip ring.

http://www.moflon.com