The U.S. offshore wind industry has finally launched with the first few foundations for the Block Island wind farm south of Rhode Island. While many eyes watch the construction there, a dedicated team is quietly making progress with an offshore wind farm a lot closer to the Midwest: The Icebreaker wind farm off the coast of Cleveland in Lake Erie. At a recent seminar sponsored by Lincoln Electric, Lake Erie Energy Development Co. (LeedCo) VP of Operations David Karpinski provided an update on the project and introduced the audience to a clever foundation that could serve as the first of hundreds in the Great Lakes. LeedCo is a not-for-profit organization created to break the ice, so to speak, and get the wind industry going in the region.

LeedCo’s job is to marshal the plans, permits, ports, and manufacturing capability of lakefront cities in Lorain, Cuyahoga, Lake, and Ashtabula counties. Authorities in Erie Pa recently joined the effort. “For stakeholders, the local air quality is an important issue because of several coal plants along that lake,” says Karpinski. But talk about potential. All the U.S. offshore areas could produce a staggering 4,000 GW.

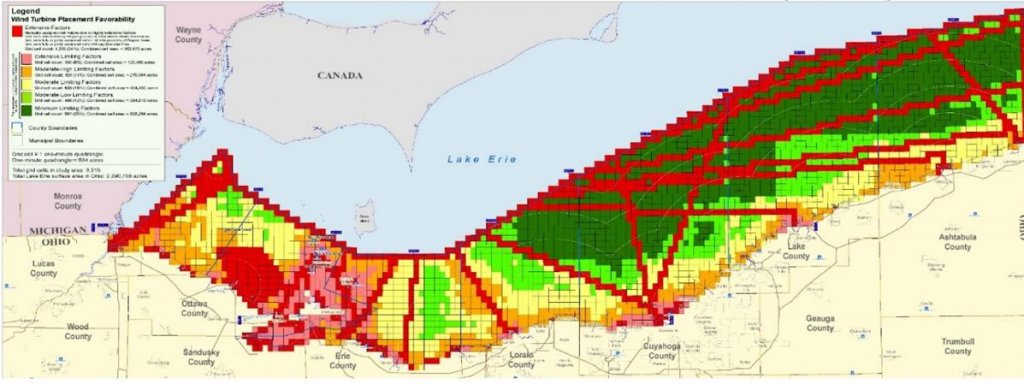

A few years ago the state of Ohio mapped each square mile of the lake for its development potential. Red areas are major obstacles, mostly shipping lanes and sensitive areas, wildlife zones, and fisheries. Green areas have no restrictions and many of those are at eastern end of the lake. The northern half of the lake is Canadian water.

The south Lake Erie shoreline is part of the PJM grid, one that Karpinski calls possibly the most progressive operator in the country. PJM released a study about 18 months agoyears ago to survey the renewable energy in its region. Study authors also said it was to “…perform a comprehensive impact assessment of increased penetrations of wind and solar generation resources on the operation of the PJM grid. The principal objectives include:

- Determine, for the PJM balancing area, the operational, planning, and energy market effects of large-scale integration of wind and solar power as well as mitigation/facilitation measures available to PJM

- Make recommendations for the implementation of such mitigation/facilitation measures.”

Although the authors found little good land-based development in Ohio, when considering distributed generation, Lake Erie looks pretty good. The population density and load centers along the lake are also good. So the pilot project, Icebreaker, makes good sense.

Like most initial U.S. offshore wind farms, Icebreaker will start off relatively small, just six, 3-MW Siemens direct-drive turbines for about 18 MW in 18-m deep water.

The site selected in Lake Erie is about seven miles off the port of Cleveland with a connection into the Cleveland Public Power substation. The interconnection was finalized in June 2015. And speaking of financing: “A renewable energy project must have all the offtakes or power committed for the life of the loan, so you need to have all energy committed for 15 years,” says Karpinski. Not many industries have to do that. One LEEDCo

financial advisor observed that no office building must have all its space rented for 15 years before construction begins. “But renewable energy has different rules, probably because of the higher risks involved,” suggests Karpinski.

Things seem slow going because no one in the U.S. has done this before. In addition, the small size of the project drives costs up. One estimate is that power from the project will be about three times the market price. How will that issue be handled?

“We have voluntary offtakers, enough people in the region that believe in the vision of a new industry that will create jobs and are willing to take a piece of the power. This participation works because the project is small. Cleveland Public Power is buying some power, the county is taking some, the Northeast Ohio Public Energy Council is taking some, and so are a lot of local stakeholders. People are willing to buy this power to make the project happen, and that makes it work here,” says Karpinski.

These home-grown solutions are acceptable for the pilot project, but would be questionable for a larger follow-on project. Target power cost in the industry is 10 ¢/kWh, much less than the current prices in Europe. Sweden’s Vattenfall just announced a project that will produce power for about 12.5 ¢/kWh and that is low for Europe. (For further reference, a recent electric bill from AEP shows a power cost of 8.19 ¢/kWh and a total cost of 14.51 ¢/kWh with transmission.)

The Finns put a wind project in their Bay of Bothnia several years ago. The ice it gets every year would qualify for the worst in 25 years for Lake Erie. What’s more, go far enough in the bay and water salinity approaches that of fresh water. It is almost like a freshwater lake making it similar to Lake Erie. LeedCo has been collaborating with the main structural engineers there on the ice considerations in Lake Erie

The cost drivers for offshore power costs are capital expenditures and operating expenditures. Opex is high and must be driven down. “Siemens has done a lot to drive Opex down, especially on the 3 MW direct-drive units selected for the project,” he adds. Even though larger offshore turbines are available, the small project size and limited offshore experience make the Siemens 3.0-MW units more manageable.

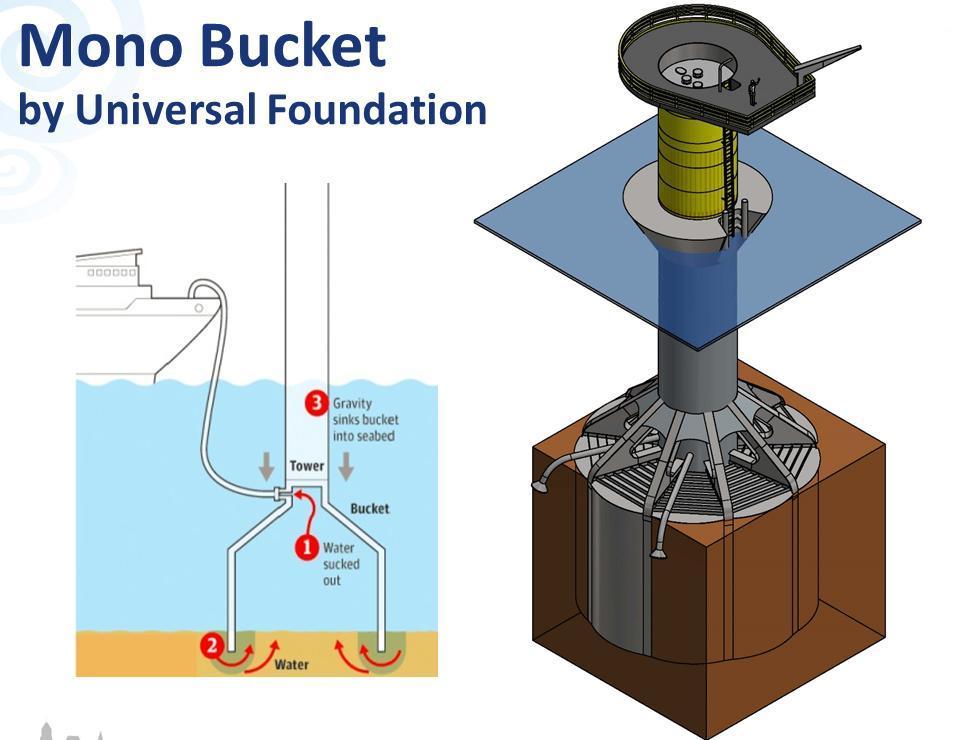

For the foundation, most European installations are on monopoles, which is good for relatively shallow water. But some question the ability of a monopole to scale up for larger turbines. Karpinski says Denmark’s Dong thinks it can scale it up for an 8-MW machine.

Jackets, such as those used at Block Island, and twisted jackets are considered for larger turbines in greater water depth. “We considered a monopole three years ago and found a challenge in Lake Erie soils. “The soil depth reaches down only 80 ft. and then bedrock. Eighty feet sounds like a lot, but it is not. Below the surface layer, at the mudline, the soil is soft for several meters. There is not enough lateral stability there for a monopile,” says Karpinski. It would be possible to drill into the bedrock but that is expensive.

Another concept takes a monopile and modifies it with what is call a friction wheel. But this solution has no track record and that makes it too risky.

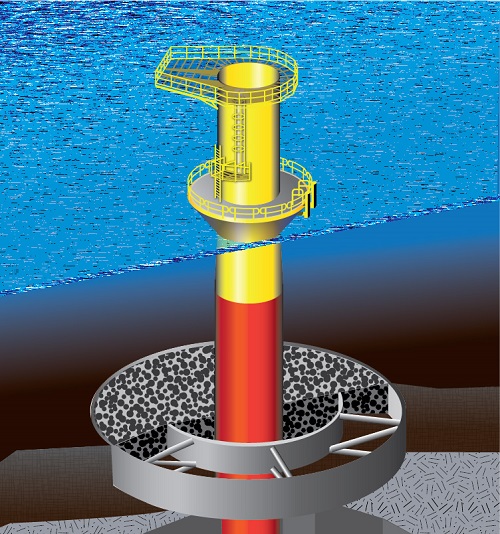

“Then we started to hear more about this monobucket. . It is based on a suction bucket technology that has been used for 20 years in oil and gas industries, mostly for anchor points. It works like this: The underside of the bucket is open and initially sits on the lake bed. It settles a little under its own weight to establish a seal, and then pumping the water out lets differential pressure drive it into the lakebed. Deeper water works in its favor,” says Karpinski.

It’s also critical to mount the turbines on a nearly vertical pile, so the bucket must be installed no more than 0.5° from vertical. “To keep it vertical during insertion, water jets are fixed to the bottom of the skirt in three zones. Should it begin to tip, the installers can activate water jets to displace soil and straighten it. What’s more, chambers on the inside of the bucket provide sections that can be pressurized separately for additional corrections,” he says.

An early foundation configuration, now abandon, modified a monopile with a friction wheel. This design had no track record and so was set aside in favor of the monobucket.

For additional confidence in its methods, Karpinski says the bucket design firm Universal Foundation (UF) conducted a series of installation trials. Over 28 days, a crew installed and removed a bucket 16 times at 16 different sites in the North Sea and was able to achieve 0.1° verticality in each case. UF says this accuracy negates the need for a separate transition piece with its problematic grouting – reducing steel, offshore operations, and exposure to delays, resulting in significant cost reductions.

Karpinski adds that his team was attracted to the one-piece structure because there is no need for excavation and no pile driving. Also, it weighs about 25% to 30% less than the monopole friction wheel, although the fabrication costs will be about the same. “What’s more, we can optimize the design, and with history, its cost can come down.”

At least three of the foundations are in service. UF has been working on the device for 15 years. One installed in Denmark 2002 holds a Vestas 2.3, and two others hold met masts in the North Sea.

After a manufacturing analysis, Karpinski’s team decided the bucket would be the better choice. The DOE liked it better than the friction wheel, too, because it has a track record.

The monobucket selected for Icebreaker will sport an 11-m long skirt and a 15-m diameter. Pumping out water from the inside will let water pressure push the bucket into the lake bed. Other mechanisms will keep the foundation almost perfectly vertical. The ice cone at the water line will break up ice flows.

Another part of the project is to Americanize the monobucket. It is a European design, specified to European standards by a Danish company. The design will be re-specified to U.S. materials and welding standards. This is where manufacturing consultant Patrick Fullencamp at GLWN will assist. Also at the conference, Fullencamp says his study would be to design for automation and to reduce the number of welds.

A local welding fabricator, AT&F in Cleveland, will be able to build the structure.

Ultimately, the bucket will have to be fabricated on the water, but there are shipyards around for that operation. “There are also dry-docks and barges along the lake. Turbine-tower manufacturer Ventower is another possible fabricator, and it is possible to get different components from different shipyards. The goal is a competitive design,” says Karpinski.

The bucket for the Lake Erie’s Icebreaker will look something like these, which are ready for a European installation. The design has been working in Europe for over a decade.

Ice is another design consideration. Ice does two things and its loading can be calculated. The cone mitigates the effect of ice by forcing it down and breaking it. One load that is less well known but predictable are called keels. They form when sheet ice separates and collides forming larger chunks. “Our Finnish consultant has the calculations for that and says the ice load is about half the wind load, making it manageable. We have further commissioned an Army cold-weather research lab to conduct a study on the likely formation of ice fields. Wave loads are of less concern because they are less than those in the Atlantic and the North Sea, and there are no hurricanes in the Lake.”

Karpinski says the organization has held over 400 public meetings for support and to make its case to communities. For example, to avoid the problems that faced the now abandoned Cape Wind project, Karpinski held meetings with communities along the lake similar to those that surrounded Cape Cod. The most well to-do enclave, Bratehnal, expressed passed a resolution supporting the project.

The engineering should wrap up by March of 2016. The project is yet to finish a geotech analysis of each site and that might influence the final design of the bucket. If all goes to plan, the six Icebreaker turbines should be producing pollution-free power by November 2018.

Filed Under: Construction, Offshore wind, Towers

Was a modified oil well drilling considered?

Good start. Sounds well thought out. Would suggest bases be strong enough for 5 Mw for future upgrades.