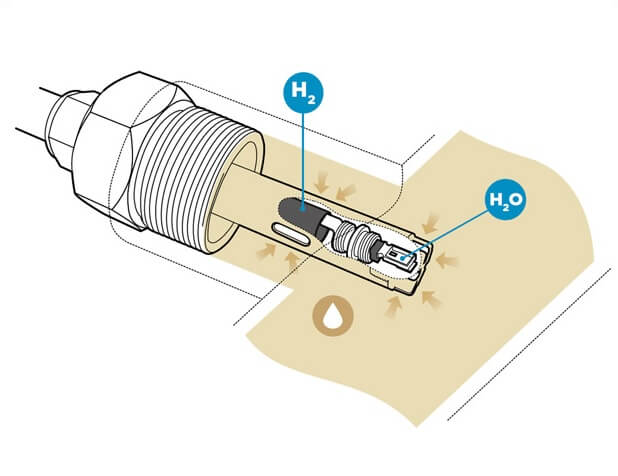

Vaisala, a developer of environmental and industrial measurement, has highlighted how online monitoring can complement more traditional sampling methodologies. Vaisala’s MHT410, for instance, quickly delivers accurate hydrogen and moisture data directly from

transformer oil. Used in conjunction with traditional methods, the device allows for greater proactivity in transformer maintenance and reduces the potential for inconsistencies in data analysis. In turn, this helps mitigate the threat of transformer breakdown and lowers the total cost of transformer ownership.

Online sampling cuts down on the logistics and travel involved by continuously measuring and monitoring transformer oil and providing real-time data on the concentration of gasses in the oil. By comparing results with transformer temperature or loading data, for example, engineers can determine whether there is any concerning correlation that warrants further action.

The MHT410 acts as an early warning system for hydrogen and moisture build-up, with its on-the-spot results reducing the need for more frequent manual sampling, and boosting the reliability of transformer health diagnoses.

“Traditional sampling methodologies have relied on scheduled, typically annual, laboratory analyses to evaluate a transformer’s health,” said Steven Jiroutek, Business Development Manager at Vaisala. “By combining these with more recent developments in online monitoring, however, utilities have much more information at their fingertips – allowing them to more efficiently monitor the state of their transformer fleet, and make better-informed decisions that will ultimately extend transformer lifetimes.”

Teollisuuden Voima Oyj (TVO), Finland’s largest nuclear power producer, has installed Vaisala’s MHT410 at one of its two nuclear power plants, to provide continuous assessment of hydrogen levels in the plant’s stand-by transformer.

Janne Jurkola, Systems Engineer at TVO commented: “Failures with large and long-standing financial consequences can be mitigated by online monitoring, as it gives information when to take proactive maintenance steps.”

“The range of features of the MHT410 made it ideal for our purposes. On top of this, it was simple to install and means we can efficiently deploy a full-scale diagnosis if required,” he added.

Manual sampling typically involves first draining several liters of oil to ensure the sample will be representative, before transporting it to a laboratory for analysis. This method allows for a number of possible sources of error, including the sample being contaminated with moisture, having some of its constituent gasses escape into the air, or it being unrepresentative of the transformer’s oil. In addition, it can be a messy and foul-smelling process that requires significant investments of time and expertise.

While traditional industry methods of oil sampling provide a momentary ‘snapshot’ of the oil’s composition at a particular moment in time, online monitoring allows for the examination of longer-term trends. In turn, these trends can reveal and help prevent the development of critical faults and transformer breakdown.

Steven Jiroutek will be speaking at Spring Industry Conference of the Centre for Energy Advancement through Technological Innovation (CEATI), being held in Indians Wells, California, on March 7 to 8, 2017.

Filed Under: Transformers