Modern wind turbines are an important piece of our energy mix. Unfortunately, gearbox life issues have impacted their financial payback. Axial cracks in bearing raceways have become the major cause of premature gearbox failures in the latest generation of wind turbines; shortening life to as little as 1-2 years once it is initiated. Axial crack failures in gearbox bearings are rare in other industries. Why it is so common in wind turbines is a mystery that is the subject of intense research. The root cause must be understood to successfully find the solution.

Modern wind turbines are an important piece of our energy mix. Unfortunately, gearbox life issues have impacted their financial payback. Axial cracks in bearing raceways have become the major cause of premature gearbox failures in the latest generation of wind turbines; shortening life to as little as 1-2 years once it is initiated. Axial crack failures in gearbox bearings are rare in other industries. Why it is so common in wind turbines is a mystery that is the subject of intense research. The root cause must be understood to successfully find the solution.

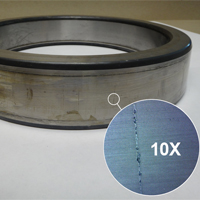

This presentation is divided into two parts. Part 1 is a review of the latest research on the phenomenon of axial cracking. It discusses how these axial cracks grow from smaller cracks that have a white color when they are sectioned and etched. These White Etch Cracks (WEC) originate from microscopic super-hard areas that also show up white when sectioned and etched, White Etch Area (WEA) damage. It appears that a threshold of rapid and severe plastic deformation must be exceeded to create these hard microscopic WEA areas. But what event in a wind turbine could cause such rapid and severe loading on the bearings? That is the subject of Part 2. It is based on recent research and field monitoring by the authors that was presented at the NREL GRC in February, 2013, along with additional research and field data generated since that presentation.

Watch this webinar to learn:

-The current status of research on the root causes of axial cracking and other bearing failures

-Field data that points to a significant root cause

-New solutions to address the root cause

Sponsored by:

Filed Under: O&M, Webinars

Hello,

I was unable to attend the webinar and access its presentation slides. Could you provide access to the presentation material and the videos ?

Many thanks.

VAsishta