An aeration windmill manufacturer in the U.S. has found that installing Vesconite bearings on its windmills lets them operate smoothly and efficiently. The bearings are an essential component in aeration windmills, which aerate ponds in private and public spaces. Blade rotation is key to ensuring that a diaphragm moves up, compressed air is taken in, and the compressor builds pressure which is released into the air line leading to the water.

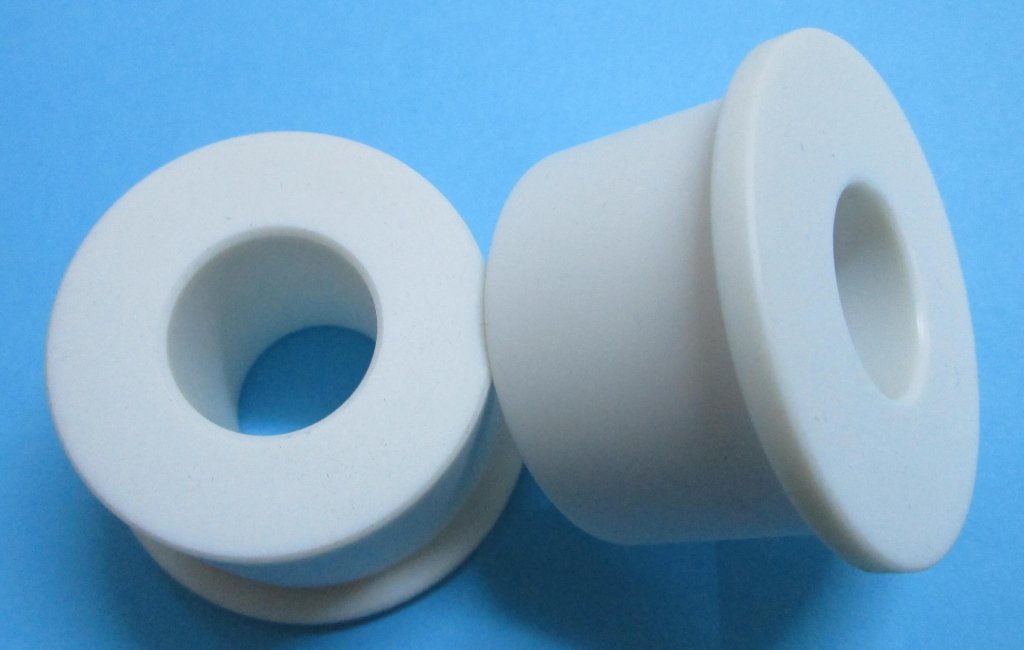

Vesconite says its bearings last up to 10 times the life of bronze bushes, and they don’t swell so they work where nylon is unsuitable.

The aerators are used to reduce algae and foul smells, control mosquitos and create a healthier environment for fish. Aeration windmills also reduce the monthly costs associated with electric aerators.

Vesconite Bearings’ Eddie Swanepoel says the 60-inch rotors spin in winds of 15 mph and weigh 35 lb. Aeration windmills and towers range from 20 to 30-ft tall. With the rotor and equipment so high up, conventional bearings are difficult to lubricate regularly, so having a bearing made of a self-lubricating polymer ensures the continued movement of the fan, he says.

As a result of the interest in its bearings for this application, Vesconite Bearings stocks the required bearings as standard stock items.

The manufacturer of the wind driven aerators is said to order about 100 bearings per year, and advertises their advantages. These “windmills” are also decorative for those interested in enhancing their gardens and ponds.

Filed Under: Bearings, News