Variation Asymptotical Beam Sectional Analysis (VABS) is an efficient high-fidelity cross-sectional analysis program and a unique tool capable of realistic modeling of initially curved and twisted anisotropic beams (blades on wind turbines and helicopters) with arbitrary sectional topology and materials. The software serves as a link between 3D solid and 1D beam models in that it is capable of reducing an original 3D structure to a beam model, and with the information obtained by 1D analysis, recovering the 3D field quantities, including displacements, and stress and strain over the cross-section of the beam.

The software has recently been extended to handle multiphysics problems including thermal-hygro, piezoelectric (coupling effects between electric and mechanical fields), piezomagnetic (coupling effects between magnetic and mechanical fields), pyro (coupling effects between thermal and electric-magnetic fields), and any combination between these physics fields in addition to the traditional mechanical analysis.

Multiphysics analysis mainly deals with the behavior of engineering structures composed of smart materials working under multiple physical fields: mechanical, thermal, electric, and magnetic. Smart materials are those that exhibit a coupling between multiple physical domains. Piezoelectrics are examples of smart materials in that they create a conversion interface between electrical and mechanical energy. Structures composed of these smart materials, which often function as actuators and sensors, are often called “smart structures”. Applications of smart structures include vibration suppression, shape control of composite plates, and aeroelastic stability augmentation. For example, embedded or surface-bonded smart actuators on a wind-turbine blade can induce an airfoil camber change that in turn varies the distribution of lift.

Although a direct analysis of composite beam structures is possible, it is computationally expensive even with advanced supercomputers. By using beam theory, the computational cost is typically several orders of magnitude less in comparison with full 3D analysis. However, one of the major barriers of smart-structure technology is the lack of reliable smart systems mathematical modeling and analysis. This barrier is caused by the difficulty of modeling coupling effects and the anisotropic and heterogeneous nature of composite materials.

Based on a powerful mathematical tool, the variatonal-asymptotic method (VAM) pioneered by Dr. Berdichevsky, a series of composite-beam models are constructed for efficient high-fidelity multiphysics beam analysis. Unlike many other beam modeling methods, the present work does not rely on any a priori kinematic assumptions which cannot handle complex geometry and significant heterogeneity over the cross-section of the beam. Moreover, it is difficult to make this kind of assumption for multiphysics analysis due to coupling effects. The newly developed beam models have been implemented into VABS, which will released with the new version VABS.

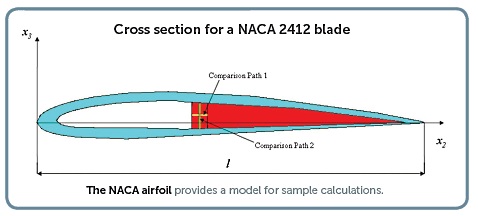

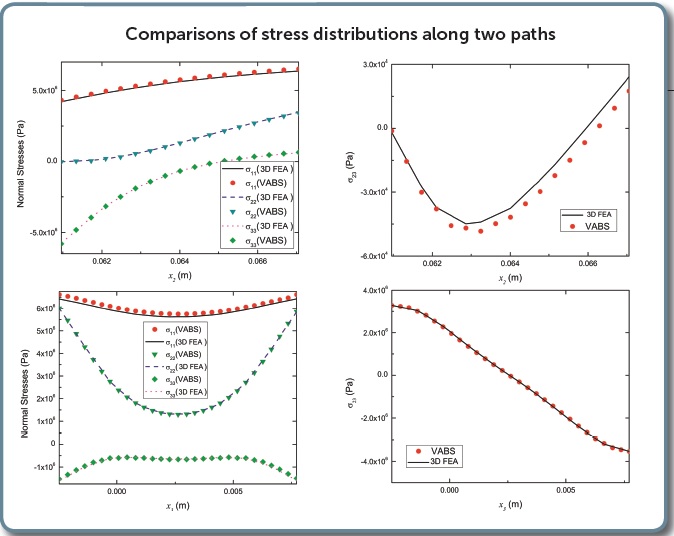

The following example shows that the current VABS has the ability to analyze a realistic blade structure at an affordable computational cost. A cantilevered beam with NACA2412 airfoil under thermal loading is used in this case. Results are compared with those obtained by a highly regarded 3D FEA code. From A comparison of stresses, it is observed that the predictions of VABS Multiphysics have excellent agreement with results from the 3D FEA code, along two comparison paths shown in the airfoil cross section. The computational efficiency of the two models is now shown.

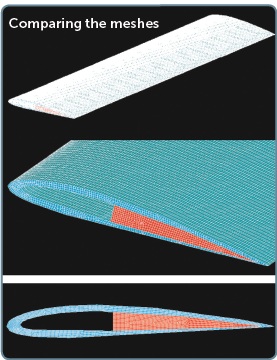

Comparing the meshes shows those used in the 3D FEA and VABS calculations. Both analysis were run on a computing server with AMD Opteron Processor 6174 2020 GHz(2 processors) and 128 GM RAM. The 3D FEA took 3 hours, 5 minutes, and 23 seconds to finish the calculation, while only 37 seconds for VABS analysis. The software comes from AnalySwift, analyswift.com. WPE

By: Qi Wang, Structural Analyst at NREL, www.NREL.gov

By: Qi Wang, Structural Analyst at NREL, www.NREL.gov

Filed Under: Software