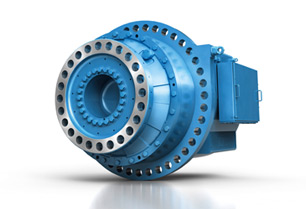

Winergy’s HybridDrive combines a two-stage-planetary gearbox and a permanent-magnet-generator into an integrated drive train.

After successful prototype testing of the HybridDrive on system level at Winergy in September 2012 and successful certification of the components in compliance with GL 2010 through the TüV Rheinland in April 2013, the first 3 MW HybridDrive has been installed in W2E’s “Wind-to-Energy” wind turbine in Kankel near Rostock, Germany. The grid connection is complete, and the turbine was commissioned in October.

After delivery of the first 3 MW HybridDrive and assembly of the nacelle in summer 2013, the W2E-120/3fc wind turbine with a hub height of 100 m and a rotor diameter of 120 m has been successfully installed.

Winergy’s HybridDrive combines a two-stage-planetary gearbox and a permanent-magnet-generator into an integrated drive train. This results in a length reduction of 35 to 50% for the complete drive train. The gearbox and generator each have an efficiency of 98% for a system efficiency of more than 96.5%. The prototype and serial tests during previous months are confirming this value of energy conversion efficiency of the HybridDrive. The 3 MW version of the HybridDrive has a nominal torque of 2,550 kNm with a weight of 34 tons, including oil supply. Thus, the HybridDrive is considerably lighter in comparison to other drive train concepts in the 3 MW class.

Winergy Systems

http://www.winergy-group.com/cms/website.php?id=/de/produkte/getriebe/hybriddrive.htm

Filed Under: Gearboxes, Generators, News