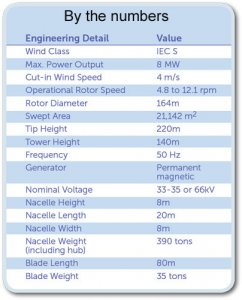

At 20m long, 8m wide, and 8m tall, the turbine’s nacelle, including the hub, weighs in at a whopping 390 tons.

Offshore wind farms are the next big thing in wind energy development and Vestas (www.vestas.com), one of the largest turbine manufacturers, is making a splash with the introduction of its newest turbine, the V164-8.0 MW.

At this writing, the 8.0 MW giant carries the world’s highest nameplate rating. Unlike other offshore turbines that are modeled after their onshore counterparts, the V164-8.0 MW is engineered with offshore conditions in mind, although its equipment and components are evolved from existing technology, including a medium-speed drivetrain.

The company says its design goals include reducing offshore energy costs and boosting profitability levels in offshore wind. In addition, the turbine’s 25-year structural design life requires as little maintenance as possible, says Vestas, and when servicing is needed, it is safe, quick, and cost effective. For instance, the 164-m rotor and 8.0-MW generator are intended to withstand the harsh conditions common in the North Sea (storm surges, high waves, and the rare tsunami), thereby increasing annual energy production.

The company says its design goals include reducing offshore energy costs and boosting profitability levels in offshore wind. In addition, the turbine’s 25-year structural design life requires as little maintenance as possible, says Vestas, and when servicing is needed, it is safe, quick, and cost effective. For instance, the 164-m rotor and 8.0-MW generator are intended to withstand the harsh conditions common in the North Sea (storm surges, high waves, and the rare tsunami), thereby increasing annual energy production.

Engineered with offshore conditions in mind, the V164-8.0 MW is intended to withstand storm surges and high waves, maximizing cost efficiency, reducing offshore energy costs, and boosting profitability levels.

Installed at the Danish National Test Centre for Large Wind Turbines in Østerild, the V164-8.0 MW has a 20-m long, 8-m wide, 8-m tall nacelle weighing 390 tons, including the hub. Eighty-meter long blades comprise the 164m rotor, increasing the swept area over previous models and maximizing energy yield from the wind, directly resulting in an increase in the amount of energy captured. In this case, the swept area is 21,124m2, the equivalent to more than five American football fields. Additionally, the turbine has a 140m tower and a tip height of 220m.

A turbine this large is good news for wind farm developers. Now they can run fewer turbines, for the same required output, and ideally, according to the company, reduce the costs for investment, operations and maintenance. Fewer turbines also means fewer foundations and less cabling. Options available for the V164-8.0 MW include a certified condition-monitoring system, aviation lights, aviation markings on the blades, a platform for techs delivered by helicopter, tower design optimized for all typical foundations, and power back up.

Construction of the foundation began in the third quarter of 2013, while manufacturing and assembly of the prototype was completed in the fourth quarter. On January 28, 2014, the V164-8.0 MW prototype successfully generated its first kWh of electricity, keeping on schedule with its timeline for development. Work on the serial production of the turbine is slated to begin in the first quarter of 2015. Testing continues on individual components, systems and integration for functional performance, reliability, and compliance. WPE

Filed Under: Featured, News, Turbines