ServoClass Couplings in both Single and Double Flex models are now available with hubs for k6 and j6 shafts. These couplings from Zero-Max provide high torsional stiffness and are designed to handle high speed reversing loads and precise positioning requirements in today’s demanding servomotor applications.

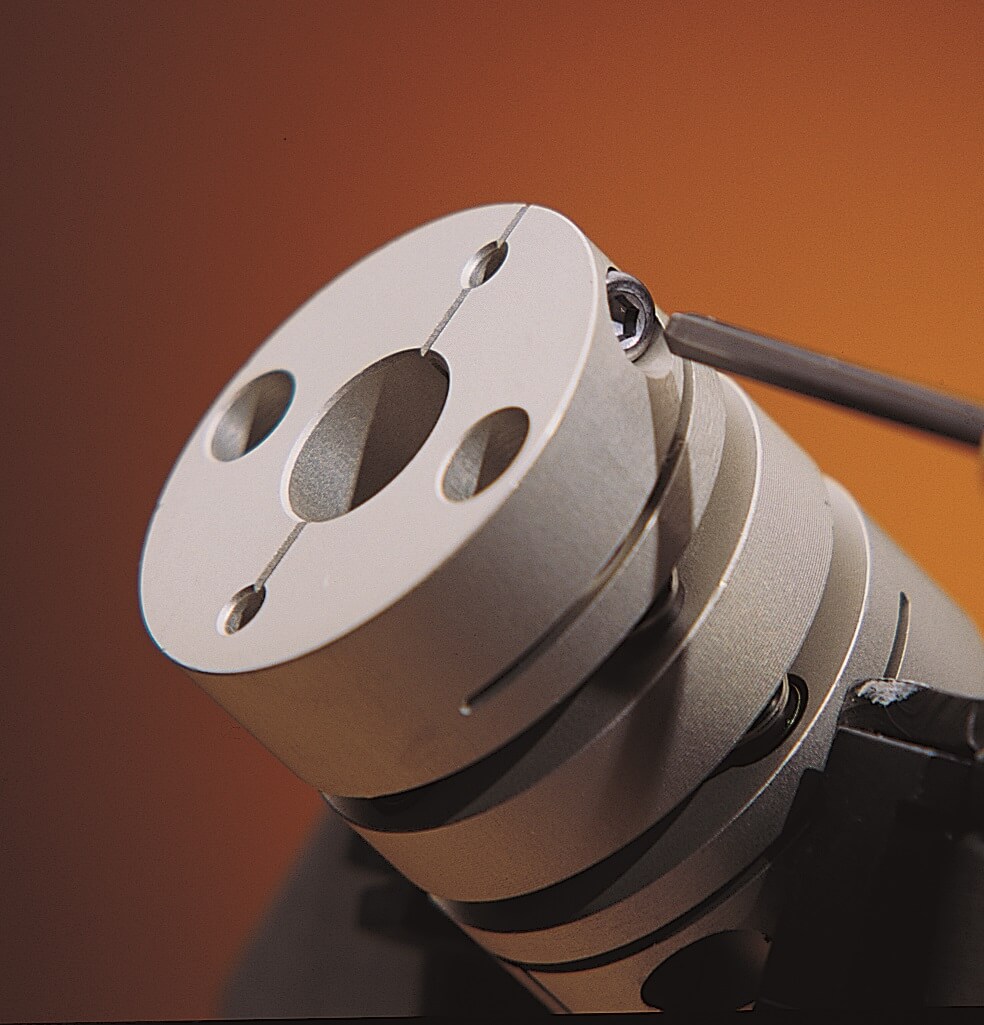

The Single and Double Flex ServoClass models handle bore diameters from 0.375 in. (10 mm) to 1.125 in. (30 mm). These couplings are lightweight with 304 stainless steel disc packs, high strength aluminum hubs and center members. All models and sizes feature clamp-style hubs with corrosion resistant socket head cap screws. All materials are RoHS compliant.

ServoClass Couplings provide zero-backlash, have an elegant, yet robust design, require no maintenance and are quick and easy to install.

With the ability to mount on k6 and j6 shafts, Zero-Max ServoClass couplings are a better choice over beam or bellow’s style couplings. They have a sleek, elegant and robust design that performs reliably in 24/7 servomotor applications. They reduce shock loads and prevent positioning errors. When the application cycle becomes faster, they outperform beam couplings, which are subject to torsional wind-up, and bellows couplings, which have a fragile design. Proof of their superiority is in their operating specifications available online.

There are nineteen sizes of standard off-the-shelf ServoClass Couplings. These couplings are ideal for clean room applications in automation, packaging, semiconductor assembly, laboratory automation, medical equipment, and for most products that use ball screws and servomotors.

For complete operating specifications, 3D CAD files, sizing software, and dimensional information, see at www.zero-max.com

Filed Under: Couplings, O&M