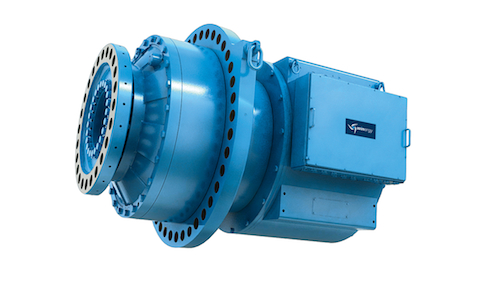

A recent wind-turbine drive combines a two-stage gearbox, coupling, and permanent-magnet generator into one compact package. One design goal for the HybridDrive from manufacturer Winergy (winergy-ag.com) is to reduce drivetrain size. A direct connection between gearbox and generator allows shortening the drivetrain by about 35% and nearly eleminating alignment tasks. The company says it demonstrates a peak efficiency of over 94%.

The direct connection between gearbox and generator allows a drivetrain 35% shorter than a similarly sized conventional unit.

Its compact dimensions present several advantages when designing a wind turbine. For instance, when the HybridDrive replaces existing machinery, it is possible to use the reclaimed space for the converter and transformer instead of mounting those in the tower. Relocating transformers to the nacelle reduces low-voltage cable losses, which further improves efficiency. Depending on design, tower costs can be reduced due to the lower nacelle weight. Transportation costs also drop because of the smaller nacelle.

Another plus is that the PM generator uses only 20% of the rare-earth materials used in similarly sized direct-drive units. Dependence on a particular and costly raw material, often neodymium, is considerably lower making long term costs easier to calculate.

The drivetrain is available with just one or a dual-bearing rotor shaft. Winergy adds that engineers can order the drive with either journal or conventional roller bearings for the planetary gears.

Despite its compact size, the drive is sufficiently modular to allow for disassembly and replacing parts when necessary. For instance, a service crane in the nacelle can lift individual drive modules. So if major service becomes necessary, there will be no need for a crane callout, which considerably reduces service costs. Furthermore, says Winergy, reliability and quality of the drive is optimized because a single supplier is responsible for the design and quality assurance of the drivetrain.

The first design of the drive has an output of 3 MW and is intended for use in offshore turbines. The developer says the concept is easily increased to the 6 to 7 MW range.

Filed Under: Components, Couplings, Gearboxes, Generators, Turbines