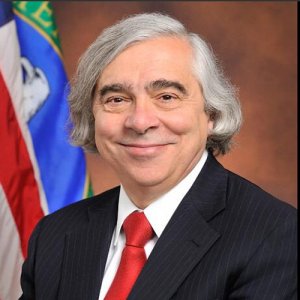

U.S. energy secretary, Dr Ernest Moniz, spoke at the Opening General Session at AWEA’s WINDPOWER 2015 event today in Orlando, Florida. Moniz stressed that wind power is an important and necessary part of the solution to climate change. Wind could provide five times what it provides today, he said, with a goal of one trillion kilowatt-hours per year in America.

To get there, new technologies are needed to boost the industry is areas where it is not yet cost-effective or as profitable as other energy sources. Moniz mentioned better siting methods, improved drivetrains, and longer blades. On the show floor, companies are certainly bringing some new and improved technologies to the wind market.

Weather measurement and assessment company, Vaisala, is aware that early siting and ongoing wind assessment has a direct impact on the long-term success of a wind energy project. The company recently launched their Nomad 3 Data Logger, a portable data management device designed to make wind measurements more economical and reliable. This data logger is also reliable in all weather conditions.

Bearing company Schaeffler is specifically addressing the common causes of main bearing failures in wind turbines. Their new asymmetric main shaft bearing offers improved axial stiffness for even higher axial load-carrying capacity. This is intended to ensure reduced vibrations within the wind turbine’s drivetrain, fewer repairs, and less downtime and overhaul costs. Other features of these new bearings include rollers coated with Schaeffler’s proprietary Triondur C coating to protect against micro-pitting damage.

While some developers are beginning to build taller turbines with longer blades when possible, blade repair solutions for existing turbines are also filling an important role in the industry. Solutions provider, Sika, is offering specialized repair kits for damaged laminate structures of rotor blades. Sikadur Blade Repair Kit is a high Tg composite resin system for wet lay-up processing that offers good impregnation and non-draining properties. It can even cure at room temperature.

The trend in services includes a focus on streamlining costs and unnecessary wind farm site visits. AVANTI is helping simplify safety certifications with a new program that manages wind turbine service inspections and provides a compliance program in one package. AVANTI One eliminates redundant service calls by providing safety inspection work with one call. Depending on the system package, up to 18 compliance inspections can be preformed based on one visit, saving time and money.

CG Power Systems also brings a form of safety to the market with their 2,700 kVA WindPAD inverter. It is designed to keep maintenance personnel outside the MV cabinet, eliminating the need for personal protection equipment. It’s gauges and valves are external to the MV cabinet. The WindPAD also has an LV molded-case circuit breaker with a safety barrier and remote operation, and a pressure-relief device. So far there is a less than 0.1% installed failure rate, making CG one of the most reliable suppliers in North America.

Even basic tools involved in the construction and maintenance of turbines are improving. Hydraulic company, Allite, specializes in tools for the industry and offers a sing-acting hydraulic wrench that doesn’t rely on an electric-power pump. With a size and weight equivalent to conventional double-acting wrenches, the new Vortex-1 also works just as fast and efficiently. It only requires one hose and offers a 360×360 swivel connection.

This is just a snapshot of some of the companies exhibiting at WINDPOWER 2015. For more information, visit www.windpowerexpo.org. The show runs until Thursday, May 21.

~Michelle Froese

Filed Under: News