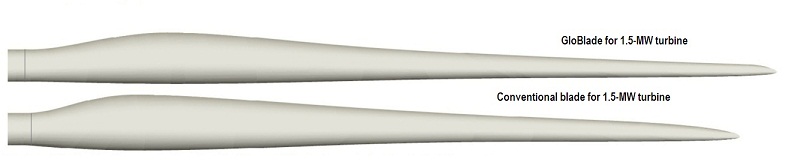

LM Wind Power’s LM 42.1 GloBlade 1 will extend the life cycle of the 1.5-MW segment by offering a design that provides annual energy production and requires no mechanical upgrading of the current platform. The blade is a way of meeting expectations for high performing rotors. By using its know-how in aerodynamics and structural design, the company developed a more cost effective blade for the 1.5-MW segment, ensuring the end user up to 5% more power generation from an existing platform.

“The market trend has been to move up in the MW range, however this presents many technical challenges and the need for customers to develop and invest in new equipment. The current 1.5-MW industry standard blades are 34, 37.5, and 40.3-m long with only the latter sold in any real volume now. This underlines the end user requirement to generate more power from an existing platform, and there are many manufacturers who offer these products. This lets OEMs sell a tested designs that offers higher electricity revenues,” says Ian Telford, VP Sales & Marketing.

Manufacturability was a key design requirement. This means that the GloBlade can be produced in most LM factories. “We expect the new blade will gradually replace the existing 37.3 and 40.3m blades. A next step is to extend the concept to create several platforms also fitting larger wind turbine types. The blade will be in full-scale production in China and North America in 2010 and in other regions in 2011 depending on demand,” says Telford. The company says that based on its projections, more than 50% of its blade sales in 2012 will be from products it does not currently sell.

The first GloBlade will be spinning on turbines in the second quarter of 2010. In China and America, about two out of three turbines installed are within this segment.

Filed Under: Blades, News