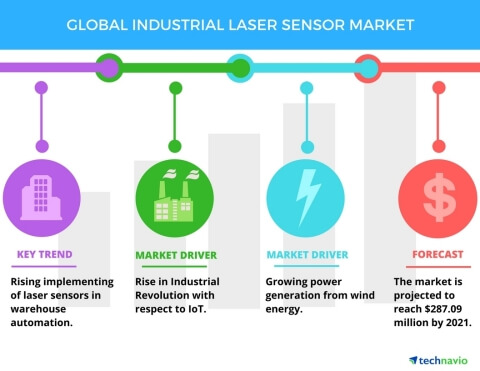

Technavio market research analysts forecast the global industrial laser sensor market to grow at a CAGR of more than 10% during the forecast period, according to their latest report.

The market study covers the present scenario and growth prospects of the global industrial laser sensor market for 2017 to 2021. The report also lists discrete industry and process industry as the two major end-user segments, of which the discrete industry accounted for more than 65% of the market share in 2016.

With a rise in wind-power generation, Technavio expects the demand for industrial laser sensors to increase during the forecast period.

Technavio analysts highlight the following three market drivers that are contributing to the growth of the global industrial laser sensor market:

- Rise in Industrial Revolution with respect to IoT

- Increasing use of CMOS displacement sensors

- Growing power generation from wind energy

Smart tech

The Industry 4.0 is a revolution in industries that are primarily focused on the automation of factories and implementation of IoT in industries.

“The emergence of smart factories has resulted in the development of sensing technologies, which are used in all industrial automation applications,” says Raghav Bharadwaj Shivaswamy, a Lead Analyst at Technavio for Automation Research.

Industry 4.0 enables advances in industries by converging industrial systems with the competence of advanced computing, analytics, and low-cost sensing, and new levels of connectivity enabled by the Internet. A few of the technologies supporting this revolution are cloud services, Big Data analytics, and pervasive sensing technologies.

“The incorporation of sensing technology in industries ensures accuracy and consistency,” addsBharadwaj Shivaswamy. “Key developments in industrial laser sensors owing to the evolution of the Industry 4.0 include two-way communication in factory control systems by adding IO-Link interface capability to sensors.”

CMOS displacement sensors

Complementary metal-oxide-semiconductor (CMOS) optical displacement sensors are less expensive laser displacement sensors, which are superior to traditional displacement sensors such as eddy current and capacitive sensors. These laser displacement sensors are well-suited to make difficult thickness measurements.

Laser displacement sensors can measure just about any target material equally well. They have high operating ranges with standoff distances ranging from a few inches to several feet. On the other hand, capacitive and eddy current have operating ranges of tenths of inches. The large standoff range not only enhances the usability of laser displacement sensors, but also allows changes in the thickness of lasers without any need to reset the sensors.

CMOS laser displacement sensors are compact. In addition, they incorporate bulky controllers and control electronics within the sensing head.

Growing wind

Depleting conventional resources and growing greenhouse gas (GHG) emissions are encouraging countries worldwide to shift their focus toward renewable sources to produce power. Wind power is the most efficient source of power generation among all the renewable energy sources. It is also one of the most abundant sources of alternative energy.

“Rising awareness about the benefits of wind energy is fueling the demand for automation,” says Bharadwaj Shivaswamy. “Wind energy can increase rotational speed and energy output, ensuring a high rate of return for investors from wind projects. Industrial laser sensors are used in wind power generation to measure the speed, direction, and angle of movement of the flanges. This is because the deflection in angles affects the operational efficiency of producing energy.”

Countries such as Denmark, Spain, Germany, and the UK produce over 10% of their power by using wind energy. With a rise in wind energy generation, Technavio expects the demand for industrial laser sensors to increase during the forecast period.

Filed Under: News