Designing a wind farm requires satisfying many constraints. The ultimate goal is to maximize energy capture while minimizing wind loads on turbines, balance-of-plant costs, and maintaining all setback and avoidance criteria. This complicated task is most easily accomplished with assistance from specialized computer programs developed just for the wind industry. The most widely used program, WindPRO, developed by EMD in Denmark, has been used by the industry with continual improvements for over 20 years. In one computer model it combines all the information needed to efficiently design a wind farm.

It works like this: A designer inputs digital background maps (topographic maps, orthographic imagery, or other graphics) digital elevation data, wind data, surface roughness information, GIS data such as property lines and road-center lines, along with wind-turbine power curves to create a 3D computer model. Changing alterable data allows optimizing the wind farm. The software helpslets designers determine annual energy output, calculate noise emissions, shadow flicker, visual impacts, along with photo-simulations that show how the landscape will look with turbines up.

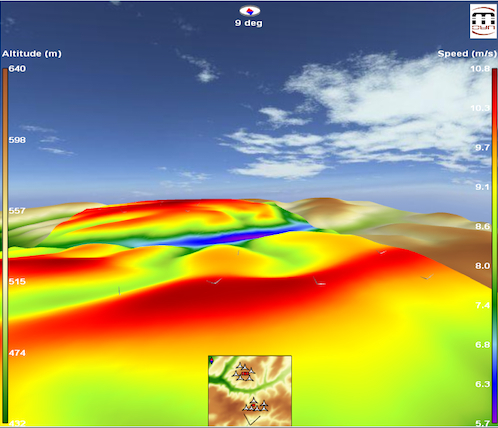

Your Landscape will look like this when the wind farm is complete. WindPro software generated this image.

The layout

Turbine arrangement is one of the most important aspects of a wind farm’s design. A small change in the layout can result in a significant difference in annual energy output, which in turn can translate into hundreds of thousands of dollars per year in revenue.

To maximize energy output, wind-farm designers try to take advantage of the natural speed-up effects that occur on hill tops, while at the same time, minimizing wake-induced turbulence that results in energy loss (array loss) and increased mechanical loads on the turbines. To minimize wake interactions, designers must maintain sufficient turbine spacing, especially in the predominant down-wind directions.

Wind-farm designers also must satisfy numerous setback and avoidance constraints, such as a safe distance from public roads and environmentally sensitive areas. A sufficient distance must also be maintained to minimize the effects of noise emissions and shadow flicker on nearby residences. WindPRO easily factors in avoidance areas and setbacks to approve turbine areas. Multiple iterations may be required to determine an optimal array that maximizes energy output while satisfying all siting criteria.

Predicting annual energy output

To predict a wind farm’s annual energy output, it is necessary to predict the wind speeds at each turbine throughout the wind farm, as well as array losses. This requires wind-flow modeling. It predicts hub-height wind speeds at various turbine locations based on measurements taken at a different location (not always within the wind farm) during the site assessment and usually at a lower height. Computer models take into account the influences of the surrounding surface roughness features, topography, and local obstacles on the measured speeds, and then incorporate those influences into the predicted hub-height speeds at each turbine location within the farm.

The most widely used linear flow model, the Wind Atlas Analysis and Assessment Program (WAsP) – developed by RISØ at the Danish Technical University – is typically used for wind-farm design where maximum slopes encountered are less than 40% (22°). The WAsP model assumes laminar flow with no flow separation, a phenomena that develops at slopes of about 30% (17°). For complex terrain with steeper slopes, a non-linear model may be necessary, such as Meteodyn, a Computational Fluid Dynamics (CFD) program that can capture higher-order effects.

The image is generated by computational fluid dynamics that examine a sample of terrain, indcating whee the wnd is highest. ehnce, it notes where wind turbines will be most productive.

Currently, WAsP calculations are handled seamlessly within WindPRO, whereas CFD models must run independently and results imported into WindPRO for further processing.

While WAsP and CFD codes are useful tools, both have problems when dealing with large arrays, complex terrain, and forested sites. When modeling such sites, the wind farm designer must make many assumptions that can result in a wide range of wind-speed predictions. A lot of recent research addresses these issues to improve model performance.

Even with all the tools available, it still takes experience, scientific knowledge and engineering judgment to properly design a wind farm and accurately predict an annual energy output. Today’s modern computer tools are helpful, but as with any computer modeling, it is the user’s responsibility to determine the quality and appropriateness of the inputs and the reasonableness and accuracy of the results.

Jay Haley

Partner, Mechanical Engineer

EAPC Wind Energy

Grand Forks, ND

www.eapc.net

WPE

Filed Under: Construction, Projects