Both DTX XFFL Range Tubular LED Fittings and XLF Range LED Floodlights are manufactured with low–copper, marine-grade aluminum castings, and are finished with offshore-grade paint.

DTS, a leading Thomas & Betts global brand for hazardous lighting and cabinets, now offers emergency lighting, linear tubular lighting and floodlights with the efficiency and durability of light-emitting diode (LED) technology. DTS is well recognized in the burgeoning IEC hazardous location market, and all three fixtures offer ATEX or IECex Zone 1 certifications.

“The availability of LED technology in DTS’ industry-leading Series XFFL tubular lighting and Series XLF floodlights brings longer service life, greater energy efficiency, and vibration and shock resistance to lighting for hazardous locations,” said Christophe Janin, director, hazardous location products, at Thomas & Betts Europe. “The tubular luminaire and the floodlight are the two most popular items in DTS’ catalog, and by offering them with LED technology, its benefits are available for applications in oil and gas processing, as well as food and beverage, pharmaceutical, and chemical processing.”

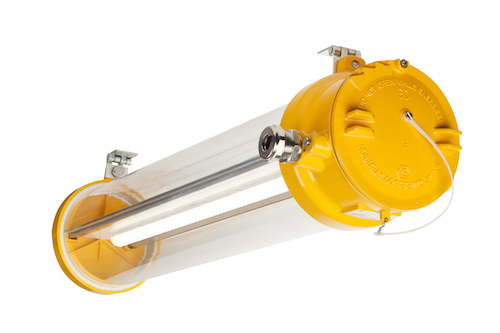

The DTS XFFL Range Tubular LED Fitting offers an operating life of more than 100,000 hours, output of 5,000 lumens with 100% yield, and components mounted on a sliding gear tray to facilitate installation and maintenance, and may be retrofitted into existing fixtures mounted with T8 lamps. The DTS XFFL LED tubular luminaire includes a cable gland and brackets, and is available in polycarbonate or glass.

The DTS XLF Range LED Floodlight offers an operating life of more than 50,000 hours, narrow-beam output of 9,000 lumens and wide-beam output of 7,000 lumens, and instant-start illumination and instant re-strike. It will operate in cold environments without needing to warm up. The DTS XLF LED floodlight includes a cable gland and an integral junction box.

Thomas & Betts’ DTS

www.tnb-hazardous.com

Filed Under: News, Obstruction lighting, Turbines