The market for wind power is growing fast around the world. Two driving factors include higher prices for fossil fuels and concerns for their environmental impact. Also advancing is the efficiency of wind powered generators it’s steadily improving. One way electrical engineers are improving turbine efficiency is with higher voltages. A simple equation,

P = VI

shows the relation between voltage and power, where:

P = power, watts

V = voltage

I = current, amps

Increasing the voltage allows decreasing the current for the same power output.

Capacitors are increasingly used in a turbine’s circuitry to reducepower losses in its alternator and converter.

Wind-power generators once used capacitors with a working voltage of about 650 Vdc, but today’s “sweet spot” ranges from 800 to 1,350 Vdc and higher with direct power conversions. The upper voltage depends on the alternator’s output ac voltage. Higher voltages allow lower rms current for the same power. In this area, dry metallized film and non-gas impregnated-film capacitors offer significant technical advantages over previously used electrolytic capacitors.

The FFLC large capacitor from AVX occupies about 40 liters while it holds a 1,900 Vdc charge at 27mF.

For example, power film capacitors, such as those from AVX, can provide a boost to wind power stations with high capacitance values, units with up to 48,000 μF (micro farads) are available. Lower voltage and lower current capabilities in electrolytic designs mean having to use several in series or parallel for the same function.

Several advantages

A big plus for film capacitors is their ability to overcome internal defects. The latest dielectric films used for dc-filter capacitors are coated with a thin metallic layer, often aluminum, zinc, or an alloy.

Should a defect occur, the metal there evaporates and isolates the defect, effectively self-healing the capacitor. Because wind power systems are normally located in remote locations, this feature can significantly reduce maintenance costs and ensure higher efficiency for the installed system. Although a quick search reveals several “segmented metallized film technologies” on the market, not all are controlled or self healing.

The main advantages of this technology include:

• Proven field reliability with zero catastrophic failures even under severe usage

• Designs maintain the highest electrical and mechanical specifications

• Long-life expectancy

A technology comparison

It’s useful here to look a bit closer at the two competing designs for capacitors. For example, the thickness of alumina used in electrolytic capacitors is key to reaching higher voltages. However, there is a trade-off: The higher the voltage, the lower the available capacitance. In addition, at higher voltage (500V and up) electrolyte conductivity drops to 5 kΩ/cm compared to about 150 kΩ/cm for lower voltage versions. This also limits rms current values to about 20 mA/μF. For film capacitors, the values are about 1 A/μF.

Dc-link capacitors with a self healing capability for wind turbines are well suited to new energy applications. The main power film series from AVX includes FFVE, FFVI, FFLI, FFLC and Trafim. These provide a wide range of form factors, capacitance, and voltage options that cover most applications, with custom designs for specific requirements.

Another requirement for dc-link capacitors is to handle ripple current. For a capacitor, it is a voltage variation described by:

I = C dV/dt

where

I = current

C = capicatance, farads

dV/dt = change in voltage over a change in time

The voltage gradient in today’s dry-film capacitors can reach more than 500 V/μm for discharge applications and 250 V/μm for dc filtering applications.

These film capacitors are designed to CEI 1071 standards, which means they can handle multiple voltage surges of up to twice their rated voltage without significantly decreasing product life. Designing to the standard also means an engineer need only account for nominal voltage requirements when specifying a system.

Using film capacitors would also mean the engineer need only consider the minimum capacitance value required for a system. As a result, designs which use film technology frequently save space. This is important when you consider that this application places capacitors inside a converter.

Aluminum electrolytics, on the other hand, would require using banks of several capacitors, not because a higher capacitance value is required, but simply to handle the current.

Reaching today’s higher voltage requires connecting multiple electrolytic capacitors in series. This would further require balancing the voltage by connecting resistors in parallel with each capacitor because the IR (insulation resistance) of each individual device varies. This results in an overall increase in direct leakage current, which is equivalent to lowering the overall system IR.

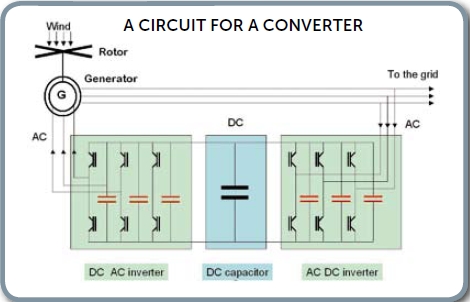

The circuit diagram is for a converter for a wind turbine application. The converter uses several capacitors. The dc-filter film capacitor is in the center.

Surge voltage is another consideration. Aluminum electrolytic capacitors can withstand surge voltages of only about 1.2 times the nominal voltage. In contrast, higher voltage film capacitors (over 1,350 V) are filled with a nontoxic organic oil and can operate up to 100 kV. These capacitors, along with dry-film versions are considered environmentally friendly because they do not use acids and therefore pose no risk to the system. Both dry and oil filled capacitors can also be stored without concern because they have no “dry out” or wear-out mechanisms as do electrolytic versions.

Reverse or over-voltages more than 1.5 times the rated voltage can cause a chemical reaction. If it lasts long enough, the capacitor may suffer catastrophic failure, to the extent of developing a short circuit or a pressure release where the internal electrolyte may evaporate. To overcome this, a system designer would connect a diode in parallel to reduce the potential problem.

So although it is technically possible for aluminum electrolytic capacitors connected in series to attain the necessary higher voltages required by today’s wind energy applications, the circuit design can be problematic, require additional components, or additional protection to ensure successful operation.

Life expectancy

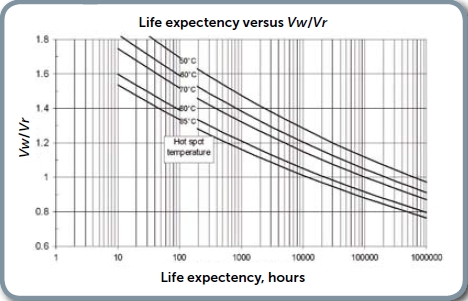

Ultimately, the big advantage of film capacitors over aluminum electrolytic designs is life expectancy. Internal data shows that AVX controlled, selfhealing, dc-filtering designs capacitors exhibit a maximum capacitance drop of just 2% after 100,000 hours operation. Considering that a complete device failure is unlikely, it should not be necessary to change the capacitors during the life of a wind turbine. This is a big maintenance saver.

Filed Under: Safety