GE Renewable Energy unveiled its brand-new 4.8–158 onshore wind turbine, GE’s largest high-efficiency turbine to date. Featuring the largest rotor in the segment and innovative blade design, the 4.8-158 offers a significant improvement in Annual Energy Production (AEP), reducing the cost of energy for customers with low to medium wind speed sites.

GE’s new 4.8–158 onshore wind turbine features an innovative blade design that helps reduce the cost of energy for customers with low to medium wind speed sites. Learn more here.

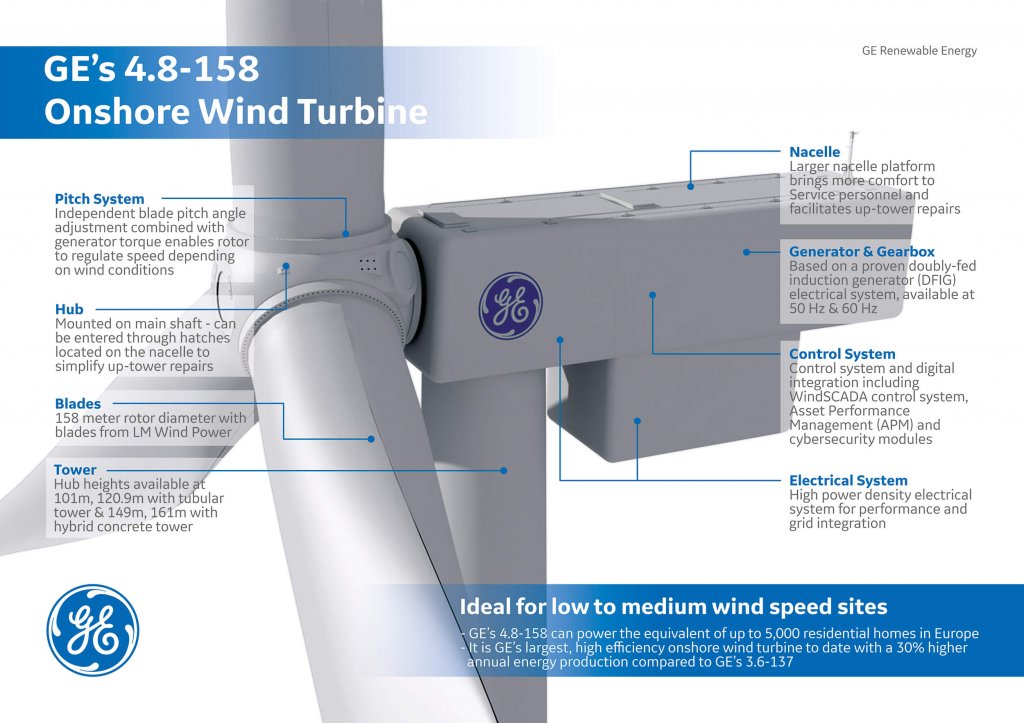

The new 4.8-MW wind turbine, GE’s first onshore entry in the 4-MW space, is equipped with a 158-meter rotor and a range of tip heights up to 240 meters. The combination of a larger rotor and tall towers enables the turbine to take advantage of higher wind speeds and produce more energy.

“The 4.8–158 design is an important next step in turbine technology and efficiency, and we’re excited to introduce this turbine at this moment in time,” said Pete McCabe, President & CEO of GE’s Onshore Wind Business. “It is well suited for low to medium wind speed regions worldwide — examples include Germany, Turkey and Australia — as well as for mechanisms like auctions, as countries around the world are putting an increased emphasis on lowering the cost of energy.”

GE’s latest turbine features high tech blades, improved loads and controls, and taller, more cost-effective towers. These new innovative features have been developed thanks to close partnerships with LM Wind Power, Blade Dynamics, and GE’s Global Research Center.

The 77-meter-long carbon blades leverage the strong track record and material innovations of LM Wind Power and are their longest onshore blades to date. These carbon blades will enable flexibility, allowing GE to offer its customers a high-efficiency product while continuing to drive down LCOE. The blades also feature one of the industry’s smallest Bolt Circle Diameters, keeping manufacturing and logistical costs to a minimum.

“This turbine is a great example of what we can achieve through the GE Store, combining technology and development with innovative design and expertise from the Global Research Center, LM Wind Power, and Blade Dynamics,” added McCabe. “We collected input from more than 30 customers around the world to ensure we are meeting their specific turbine needs with this product as they work to provide lower-cost renewable energy.”

The 4.8-158 leverages the best of GE’s 2-MW and 3-MW platforms, including the proven DFIG–doubly-fed induction generator—and a robust drivetrain architecture. The turbine meets a lower standard of noise emission levels, achieving a 104-dB level during normal operations. The newly-designed machine head reduces the needs for a larger crane while facilitating up-tower repairs and troubleshooting with its up-tower electrical system.

GE’s most powerful onshore turbine is built to leverage the intelligence gathered from across the company’s 30,000+ fleet of wind turbines. Data analyzed from this large installed base powers the 4.8-158 with GE’s next generation control system. By utilizing GE’s Predix core applications including Asset Performance Management (APM), Cybersecurity and Business Optimization (BO) solutions, our customers realize business outcomes, including lifecycle extension of the customers’ windfarms and improvement of farm economics.

Filed Under: Blades, Construction, Generators, News, Projects, Towers, Turbines