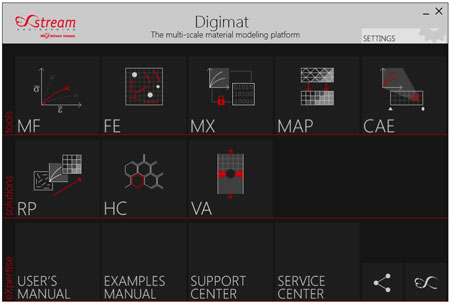

e-Xstream engineering, developer of Digimat, a multi-scale material and structure modeling platform, recently announced the release of Digimat 6.0.

This latest release brings a series of new features and improvements in composite materials for Short Fiber Reinforced Plastics (SFRP) to Discontinuous Fiber Composites (DFC) and Continuous Fiber Reinforced Composites (CFRP).

The key highlight of Digimat 6.0 is the introduction of JEC Innovation Award winner Digimat-VA, a unique software solution dedicated to accurate and efficient virtual characterization of CFRP, that dramatically cuts the cost and time associated with material characterization and qualification. For example, generating a B-basis value without extensive experimental work is now just a few clicks away. True coupon strength distribution is finally accessible. Full layup design space can be explored at the fraction of the usual cost. Root cause analysis of early failure can now be understood thanks to the variability modeling integrated in Digimat-VA. New material systems can be explored virtually. Any engineer, whether in the aerospace or the wind industry, concerned with characterizing a new composite material, exploring the design space or better understanding mechanical properties will find Digimat-VA to be a productive, efficient and accurate solution to save time and money.

Additional highlights include:

Continuous Fiber Reinforced Plastics

Digimat 6.0 offers engineers working on CFRP new curing models (curing state and shrinkage) as well as new progressive failure models and significant speedup during coupled analysis of unidirectional (UD) and woven materials.

Short Fiber Reinforced Plastics

The short fiber reinforced plastic (SFRP) world also benefits from the latest Digimat improvements and features. e-Xstream engineering maintains its dedicated focus on the advanced modeling of SFRP and provides new interfaces to FEA codes in Digimat-RP, namely Pam-Crash and MSC Nastran SOL101 and SOL103. Automatic mapping procedures have been made more robust with an improved mesh superposition algorithm. Calibration of tension/compression failure indicators such as Tsai-Wu 3D Transversely Isotropic is now available in Digimat-MX, helping material engineers to build a Digimat failure model. Finally, material properties evaluation in Digimat-FE is made easy with automated procedures to run all necessary simulations and compute material engineering constants.

e-Xstream engineering

www.e-xstream.com/

Filed Under: News, Software