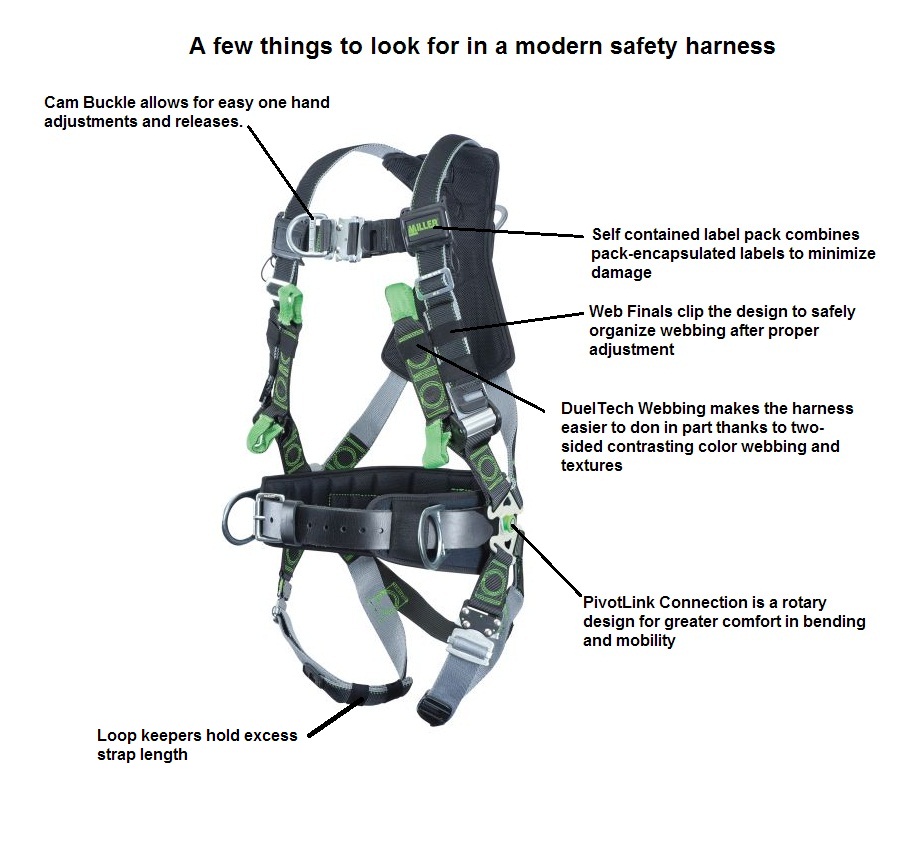

Article by Edward Bickrest, Miller by Sperian, www.millerfallprotection.com

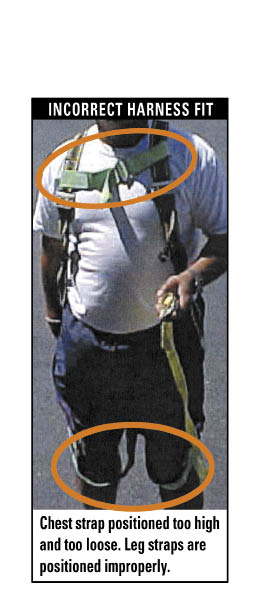

Workers on windpower job sites receive product training on properly adjusting their fall protection equipment, yet, life-threatening situations arise when users forget or ignore instructions. For example, a photograph below illustrates correct and incorrect methods of donning and adjusting a full-body harness.

A snug fit means a safe fit

While some workers mistakenly prefer loose fitting, full-body harnesses for comfort, harness designs require a snug fit to prevent serious injury in the event of a fall. Placement and connection of the chest strap, leg straps, back strap and D-ring critically affect harness fit and safety. A safety seat belt in a car will not restrain a person properly in an accident if it’s too loose, and neither will a full-body harness.

Chest straps are a critical component and must withstand fall forces without tearing or breaking during a fall. If a chest strap is not fastened properly, it can slide up around a worker’s neck after a fall.

“We’ve all seen dramatic newspaper photos of workers suspended in harnesses,” said Michael Seman, Senior Product Manager for Miller Fall Protection and Honeywell Safety Products. “If the harness isn’t snug, the chest strap can reposition itself near the user’s neck. Full-body harnesses are designed to prevent injury, but they must be worn snugly to work properly.”

Seman added that metal hardware on chest straps is the preferred choice for greater safety, consistently meeting 4,000 lbs. of ‘pull force’ when tested. Metal connecting buckles should connect in the mid-chest area to keep shoulder straps taut in the event of a head first fall. It also prevents the chest strap from sliding up in the event of a fall. Velcro has been offered recently by some manufacturers as an alternative to metal hardware. This less-than-capable alternative has the potential to collect dirt, which can affect its ‘holding power’ and result in serious injury in the event of a fall.

Leg straps are available with a variety of metal connections including quick connect buckles, tongue buckles, or mating buckles. They must be fastened snugly around the leg to work properly if a fall occurs.

Leg straps are available with a variety of metal connections including quick connect buckles, tongue buckles, or mating buckles. They must be fastened snugly around the leg to work properly if a fall occurs.

A back strap prevents roll-out in the event of a fall, and the back D-ring should be located in the middle of the back between the shoulder blades to be most efficient. In the event of a fall, this location assures you are upright while awaiting rescue.

In addition to properly adjusting a harness for a snug fit, specific job site applications require appropriate harness selections. For example, workers want to select polyester webbing for use in harsh environments where chemicals are a concern.

Another option, utility harnesses, minimize metal hardware above the waist to reduce conductivity. These harnesses are independently thermal-arc tested to ensure superior performance. Arc rated harnesses are also available that will not burn or weaken if subjected to an electrical arc.

If you are in doubt about your needs for a specific application, consult professionals so that your project can proceed safely, productively and profitably.

Remember, the harness is just one element of the personal fall arrest system. When planning your total system, carefully select components that have been proven to work together.

In some instances, components produced by different manufacturers may not be interchangeable, and some items may not meet basic safety standards.

A checklist for safety

Before purchasing fall protection products, follow this checklist of non-negotiable items, and insist on written proof from the manufacturers for the following:

ISO 9001 quality assurance – ISO 9001 certification proves a facility meets strict international standards and represents consistency in the manufacturing process.

Quality-conscious manufacturers strive to produce reliable products, and certification to ISO quality is a measure of a reliable supplier. This standard assures ongoing training, audit programs, and inspection on a regular basis.

Equipment must meet ANSI standards – Product labeling is not enough. Not all ANSI-labeled harnesses meet ANSIZ359.1 and ANSI A10.14. While OSHA regulations are the law and are enforced by a federal agency, ANSI standards are self-enforced by individual manufacturers – there is no enforcement body, and no inspectors. Hence, the buyer cannot take stated performance per ANSI guidelines for granted. If products are tested and pass the standards, a manufacturer will not hesitate in supplying the test results or documentation.

Evidence of a Statistical Process Control program – Your harness selection criteria also should include a scrutiny of product quality. Fall protection products are only as good as the quality of the raw materials and components. Expect the best, and don’t hesitate to ask for proof.

Appropriate harness sizing influences compliance – Some manufacturers accommodate all employee shapes and sizes with more than 30 styles and designs developed to meet the needs of today’s workers. One type of harness will not meet the array of applications found on today’s job sights.

Instructions – Thoroughly train employees in the correct use of equipment in order to ensure safety. The harness you choose should include clear, easy-to-read instructions in more than one language with English, French, and Spanish versions as the most common. All instructions should include explicit guidelines for usage, maintenance and inspection. WPE

Filed Under: Safety