Jon Leather

Wind Energy Technical Manager

Castrol Industrial

www.castrol.com

More than a few recent wind industry discussions have focused on the effect of high water content in wind-turbine gearbox oil. Some research suggests that high-water content could be problematic for rolling contacts (friction) and have a detrimental effect on bearing life.

The impact of water content in synthetic gearbox oil depends on whether the water content is near its saturation limit and if it fully dissolves in the lube. For O&M crews, it is important to consider the two types of commonly-used gearbox oils and how they differ.

Types of fluids

A few conventional synthetic hydrocarbon-based gear oils include those referred to as ashless, and sulfur or phosphorous additive package. In contrast, non-ashless or organo-metallic oil is also based on synthetic hydrocarbons, a special plastic deformation (PD), and a surface improvement additive package. When activated by high specific loads and corresponding temperatures, synthetic oil helps equalize roughness without creating abrasion leading to the surface improvement.

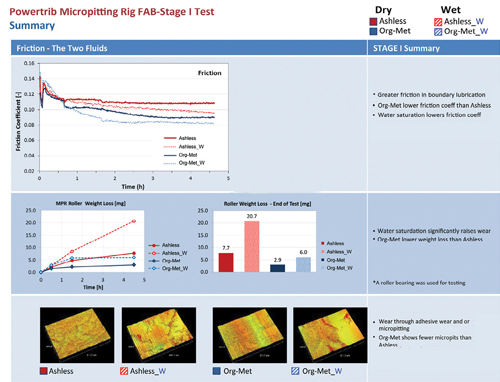

Powertrib’s testing shows the organo-metallic synthetic oil has a more favorable performance under higher water levels, than ashless conventional oil. The org-met oil maintained a lower friction coefficient. The tested roller bearing showed fewer micropits.

Organo-metallic gear oils are designed to protect and maximize the performance of wind-turbine gearboxes. This formulation offers high-load carrying capability and a low coefficient of friction with superior protection against micropitting. The oil can even reverse some gearbox damage. Extensive tests by a lubrication specialist explored the effects of water content in gear oil.

Powertrib (www.powertrib.com), an independent testing tribological research organization, conducted a series of tests to measure the effect of water in different lubricants and lubrication regimes, and report on the findings.

The poly-alpha-olefin-based, ISO 320-grade gear oils tested include:

- Conventional ashless lubricant with an additive – its typical saturation limit of water is at 60° C and around 250 ppm

- PD additive (organo-metallic) with a saturation limit of water typically at 60° C and around 1,000 ppm

Test results

FAG (Schaeffler) FE8 test simulations for wind-turbine gear oils were run using Powertrib’s triple-disc test rig. Water content for Powertrib’s testing consisted of dry, less than 50 ppm water, and wet, about 200 ppm water for the conventional lubricant and about 800 ppm water for PD oil. Tests were run at higher than normal water levels (saturated). This is considered a worst-case scenario.

In a micropitting rig test, three rings are loaded against a single barrel specimen so pitting or micropitting occurs in a relatively short period due to the load and frequency of contacts.

Test results are as follows:

- The wear increased in the boundary lubrication regime for both wet fluids. Organo-metallic formulations showed significantly less wear than the conventional ashless oil.

- Boundary lubrication typically is seen at slow speeds and high loads at start up, and shock loads where most wear occurs. Organo-metallic’s wet performed better than ashless dry in boundary wear.

- In the mixed film, elastohydrodynamic lubrication, and hydrodynamic regimes, both fluids were similar in wear protection, both dry and wet.

Overall, the organo-metallic performed well in all lubrication regimes with wet and dry fluids. Powertrib’s testing confirmed that the organo-metallic formulation actually protects against gear and bearing wear better than ashless formulations with higher water levels (800 ppm versus 200ppm) present. WPE

Filed Under: Featured, Lubricants, News