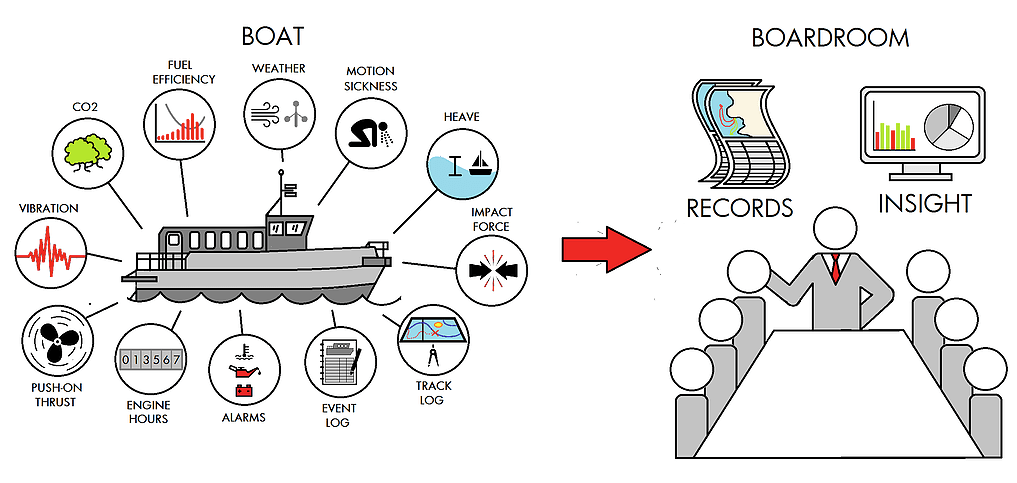

By adopting advanced monitoring systems such as BareFLEET, Reygar says that CTV operators are able to better understand the performance of their vessels in different weather conditions and under different crews. The system monitors fuel consumption, engine health, weather and navigational data, and more, making it ideal for use in offshore wind work.

The drive for openness has occurred for some time, particularly in response to rising demands from offshore wind project owners for CTV operational and performance data, says Reygar. This data, which includes motion, engine performance, weather conditions, and fuel consumption, has a strong influence on procurement decisions as owners look to increase “time on turbine” for their technicians, as well as the overall safety and cost-efficiency of their projects.

Filed Under: News, Offshore wind, Safety, Software