Automated drones are making offshore wind-turbine inspections significantly safer and more efficient than onsite manual checks.

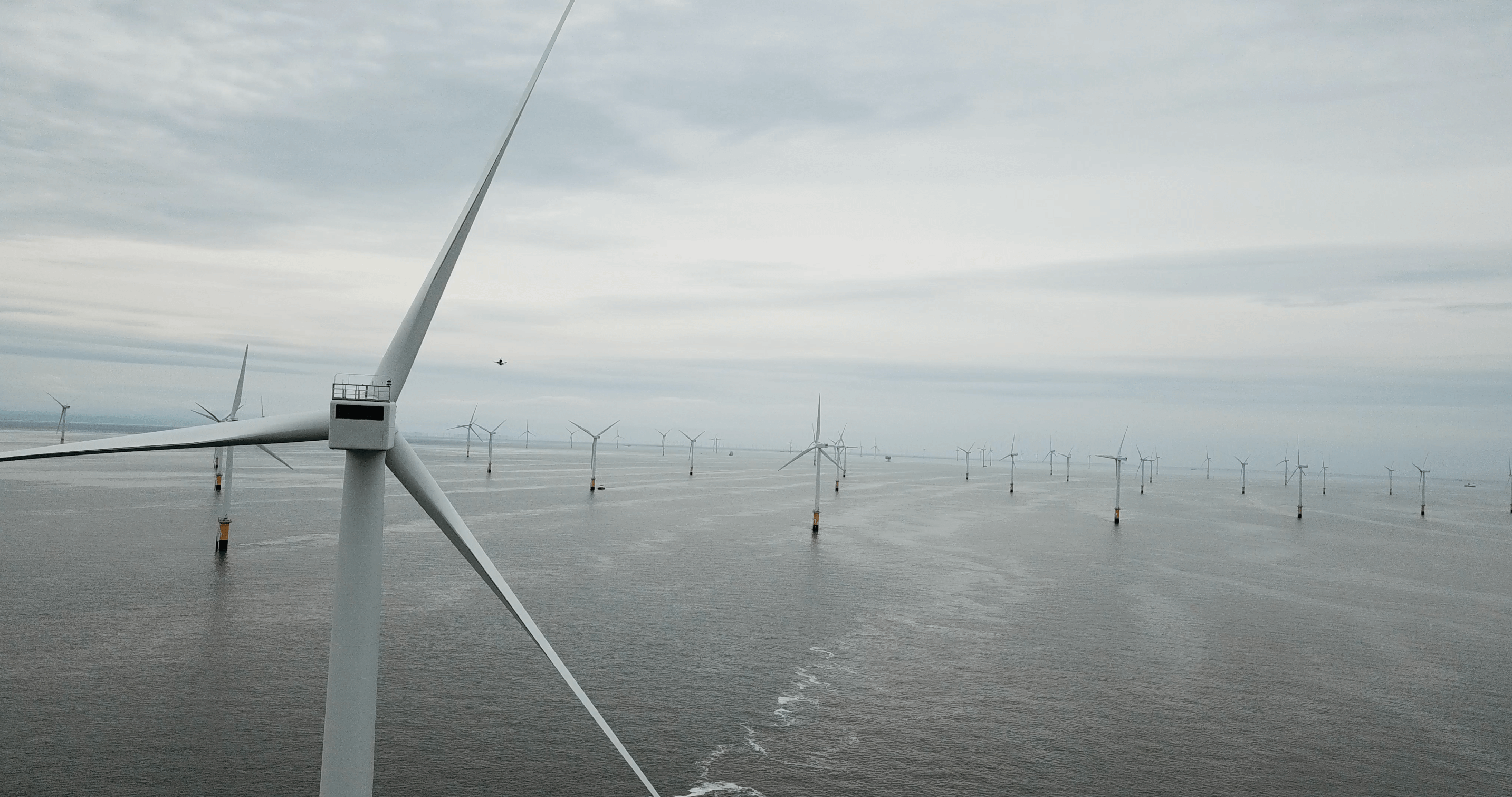

There are now 18,814 MW of installed offshore wind capacity in 17 markets around the world. Offshore wind farms are susceptible to many maintenance issues from the extreme conditions at sea, such as high wind and elemental exposure. Blade health is key to continuous turbine operation and reduced downtime.

To mitigate blade damage and predict failures before they occur, many wind owners are choosing robotic drone inspections. Speed, repeatability, and reliability may factor into the decision to use drones. In-person, manual inspections are subject to human error and can take up to a full day for a single tower and months for a full fleet.

Safety is also a critical feature, particularly at offshore wind sites. Using a drone for blade inspections is far safer than a wind tech climbing uptower in high winds and for long periods offshore. Drones can save operators additional crew-transport fees and O&M techs unnecessary and risky trips by sea.

However, selecting the ideal drone service company is challenging as more companies enter the market. Inexperienced operators are a hazard at any wind site, but the risks intensify at offshore sites where conditions are typically much harsher. Here are five tips to help with choosing an offshore drone inspection company.

Regulations surrounding commercial drone operations are in their infancy. Each country has different and changing regulations with varying standards, constraints, and approval processes. Ensure that your drone operator is compliant with local law and verify documentation accordingly.

1. Ask for automation

Operating drones offshore is a complex task. The environment is inherently unstable because of strong winds at sea, and there is a larger margin for errors in flight. As an operator navigates around the turbine blades, the wind speed and direction can change rapidly and unexpectedly because of how the turbine structure interacts with the wind.

Steadying a drone near a turbine tower and blades is challenging in turbulent offshore environments. Manual flight and inspection should, therefore, be avoided at offshore wind sites. Instead, autonomous inspection drones can maintain precise location, control, and image capture while navigating around turbine towers.

A well-executed automated flight relieves stress and prevents operator fatigue, which is common when looking uptower for long periods of time. Blades and tower present large visual obstructions that can make it challenging to get an accurate sense of how far a drone is away from the blades. Automation is safer because the drone’s sensors are far more sensitive and accurate than an operator working from the ground.

In addition, automated drone inspections typically let customers identify problem areas faster, and optimize repair schedules and costs earlier and more accurately.

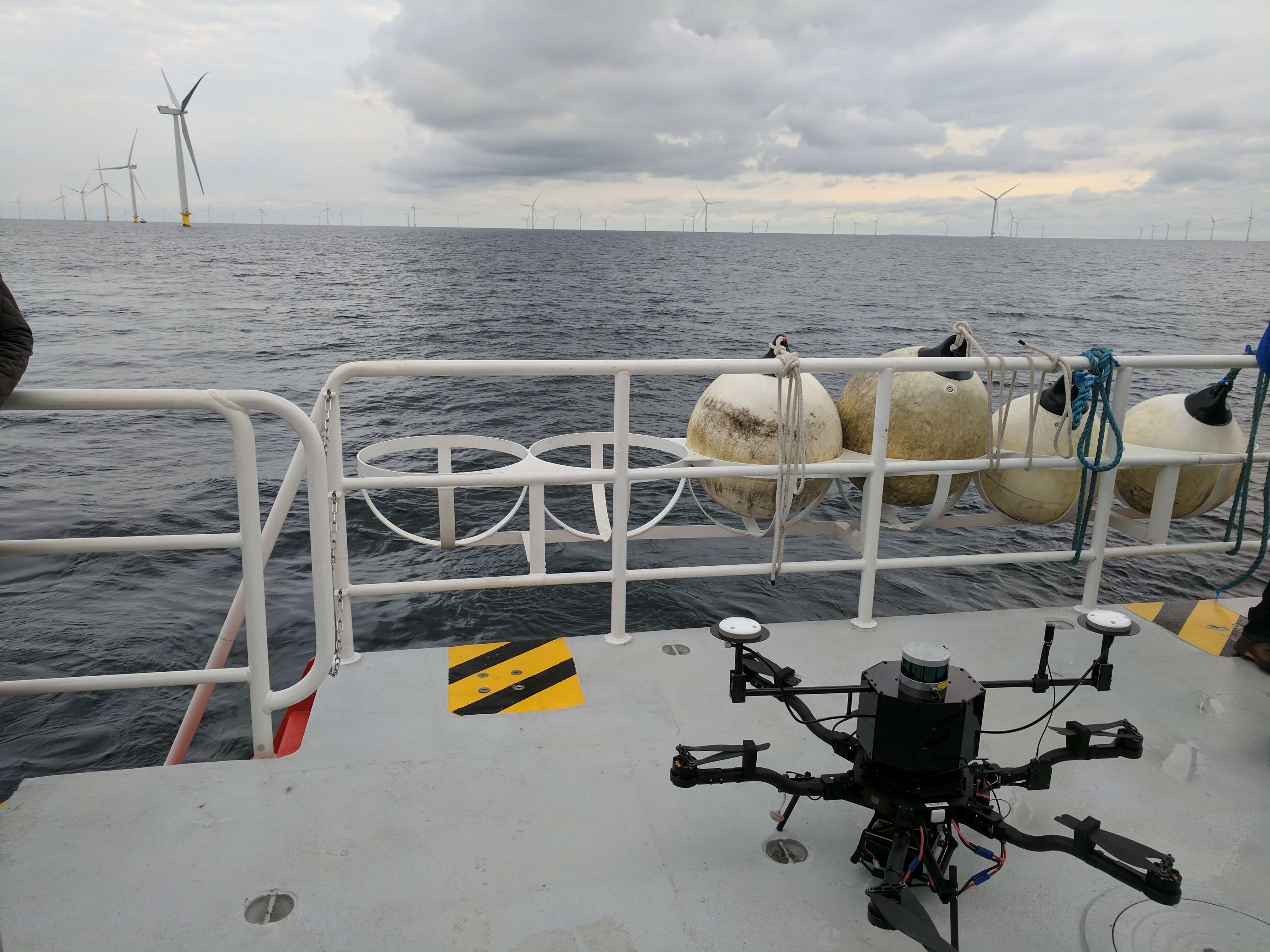

2. Choose the right vessel

Drone landings and takeoffs must be precise, and this is a challenge in less-than-optimal conditions. High winds, waves, fog, or precipitation can interfere with safety.

To lower such risks, ensure the offshore vessel used for a drone departure and landing offers spacious deck space and that it is cleared prior to flight. Use of an ill-suited vessel can result in costly equipment accidents.

A picture taken from a drone captures clear evidence of erosion on an offshore turbine blade.

3. Maximize inspection time

Optimizing field time is key to a successful and cost-effective wind-farm inspection. At offshore sites, this goal is critical because of the potential limitations of the environment. Variables such as distance from shore, number of daylight hours, and wave height play a major role in inspection success and should be accounted for prior to drone flight.

Choosing an automated service that completes inspections quickly and safely ensures the highest level of productivity and output — when the weather and offshore conditions are fair.

In ideal conditions and with coordinated site support, an experienced drone company should typically complete about 15 tower inspections on a daily basis.

4. Establish good communication

Good communication is the key to optimal working relationships. This is particularly true for projects where timing and safety are essential. A drone partner should be capable of coordinating schedules with the wind-farm and vessel operators.

A team meeting prior to turbine inspections is important to establish communication plans, discuss project outcomes and expectations, and review safety standards. At the end of a day’s work, the team should meet again to debrief to ensure the operation is working at maximum efficiency.

5. Reinforce safety

Although offshore drone inspections remove wind techs and engineers from the direct inspection process, these offshore operations are still complex and accidents can happen.

A SkySpecs’ drone automatically collects images and data during turbine blade inspections — and in less than 15 minutes.

Partner with experienced, well-trained, and certified operators. Ensure the drone operator is compliant with local law and verify documentation accordingly. Also, avoid drone “hobbyists,” who typically lack wind experience and extensive drone flying skills. They may pose a greater risk to wind-turbine site operations.

Pre-flight checks are extremely important, so make sure they are completed properly. These involve double-checking equipment is in proper working order and that hardware is functioning as required. The drone operator should have a concrete, documented process for pre-flight checks in place.

Offshore wind turbine inspections vary in comparison to onshore ones. There are far greater risks offshore that may result in asset damage, lost revenue, or serious accidents. The drone, operator, and their offshore track record should be proven and impeccable.

Filed Under: Drones, News, O&M, Offshore wind