Offshore planners and operators can now take advantage of a new tool that supports the safe and efficient execution of operations on offshore energy assets. DHI launched Metocean Risk Ops, a workability assessment application that offers access to weather window and downtime analyses to support the operation and maintenance of offshore wind farms, installations and…

Pearce Renewables acquires Mortenson’s wind O&M division

Pearce Renewables, a renewable energy engineering, operations and maintenance provider, acquired Mortenson’s O&M division, Mortenson Energy Services. Within the last year, Pearce Renewables has assembled O&M companies serving utility-scale solar, wind, electric vehicle (EV) charging and battery energy storage system infrastructure. “The combination with Mortenson Energy Services creates a full suite of services to meet…

Ardexa updates remote renewable operations toolkit with upped security

Ardexa, a global IoT platform provider, has expanded its feature set with a highly secure and fast remote working toolkit for renewable energy operations. Traditional remote access tools can be complex to install and securely manage, particularly for large portfolios. Ardexa has a simplified toolkit to enable granular access management and full portfolio oversight, including…

DNV research project aims to automate verification of offshore wind turbine inspections

DNV has launched a collaborative research project to develop an automated data processing procedure for verification of detected wind turbine blade defects, with the aim of building trust and generating broader acceptance of automated data processing techniques across the industry and to inform future regulation. “With many inspections still being carried out manually, visual inspection…

Curtiss-Wright and dolphitech team up on predictive wind turbine maintenance service

Curtiss-Wright partnered with dolphitech to provide predictive turbine maintenance and blade inspection services to the domestic and international wind market. This collaboration pairs Curtiss-Wright’s StressWave and PdP Pattern Recognition software platforms with dolphitech’s next generation dolphicam2 ultrasonic inspection technology to provide users with a comprehensive view of their wind turbine blade health. “This partnership provides…

Duke Energy Renewables adds alternative lifting services to wind turbine O&M offerings

Duke Energy Renewables is offering a service option to wind energy producers around the United States. An alternative lifting service is now available through Duke Energy Renewable Services, an operator and maintenance provider for third-party wind and solar photovoltaic facilities in the U.S. Traditional wind turbine maintenance requires cranes, a construction zone and scheduling multiple…

Aerones pivots to ground-based robotic wind turbine inspections

Aerones, the wind turbine inspection and maintenance company, has launched a new robotics system for improved precision, stability, and effectiveness, abandoning its previous drone-based system in favor of patented ground-based winch and robotic arm technology. The ground-based system allows for the automation of routine inspection and maintenance functions, such as cleaning, coating and repair. The…

Chartwell Marine, Bar Technologies unveil new offshore wind vessels

Vessel designer Chartwell Marine has partnered with naval architects BAR Technologies to support delivery of the latest generation of offshore wind crew transfer vessels (CTVs). The partnership will forward the development of new vessel designs ranging from 30-meter CTVs through to 60-meter service accommodation and transfer vessels (SATVs), making use of BAR’s patented foil optimization…

COVID-19 is leading to decreased wind turbine O&M costs and more efficient practices

As wind farm owners and investors prioritize critical equipment maintenance, reduce subcontractor reliance and adopt virtual working practices for non-essential kit monitoring and analysis, operational and technology teams have fast-tracked a new working framework for wind turbine operations and maintenance that will drive future operational efficiencies, post COVID-19. This is according to a detailed survey…

Connected drones: The next technology advance for wind turbine inspections

By Donavon Graves, Director of Business Development and Strategic Planning, Skyward – a Verizon company Drone inspections play a vital role in preventive maintenance of vertical structures, ships, worksites and horizontal infrastructure like railroad tracks and power lines. Therefore, connected drones are the next phase of this technology. In the near future, the main mode…

Solutions for aging GE 1.5x wind turbines in need of intense maintenance

By Bruce Hammett, President and CEO; and Denny McKissic, National Account Manager, WECS Renewables Not keeping wind turbines positioned toward the wind is a critical revenue killer for operators, not to mention the maintenance costs associated with slight positioning problems. Maintaining directional control requires properly functioning wind direction sensing systems and robust long-life yawing systems.…

Black Swift Technologies unveils new automated industrial inspection drone

Black Swift Technologies (BST), a specialized engineering firm based in Boulder, Colorado, announced the availability of the Black Swift E2 UAS, an American-made, advanced unmanned aerial system (UAS) specifically designed for automated industrial and structural inspections. Its advanced navigation enables the Black Swift E2 to conduct highly accurate, up-close inspections of infrastructures like wind turbines,…

Roper Partner secures investment to increase wind turbine O&M services

Rope Partner, a leader in wind turbine blade repair, maintenance and performance-enhancing services, has been acquired by funds advised by Magnesium Capital LLP. In the last decade, the global wind market has rapidly expanded, with the majority of operating capacity installed since 2009. Providing the required O&M services for these existing turbines as they enter…

The winds of change: The future of predictive analytics in wind farm reliability

By Noah Myrent, global head of monitoring at ONYX InSight Renewable energy is on the rise, now more than ever. Thanks to advances in digitization and data analytics, wind turbines can be relied on as a robust source of energy. While in the past, wind turbines were largely unintelligent monoliths monitored periodically via on-site technician…

IHS expects U.S. wind O&M spending to increase 50% by 2030

United States wind O&M annual spending is expected to increase to more than $7.5 billion by 2030, a 50% increase above 2018 spending, according to a new report by IHS Markit. According to the IHS Markit 2019 Wind Power Plant Benchmarking in North America: Technological Advancements for Operations and Maintenance, the forecasted increase in O&M spending follows…

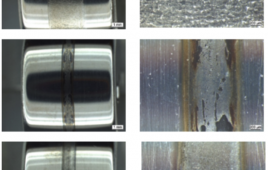

How galled fasteners may affect wind-turbine O&M

By Patrik Lundström Törnquist & Anders Söderman BUMAX Galling is a form of wear that is caused by metal surfaces in gliding contact with one other, such as the many bolts and fasteners holding rotor blades together in wind turbines. With potentially disastrous and costly effects resulting from galled fasteners seizing or even subject to…

Wind O&M and training company, Boston Energy, to set up Rhode Island operations

Boston Energy, a global wind-turbine maintenance company, will make Rhode Island the home of its U.S operations. Boston Energy, which will be based at the Cambridge Innovation Center in Providence, will create more than 50 jobs in the Ocean State. “Rhode Island is a leader in offshore wind,” said Governor Gina M. Raimondo (D-R.I.). “This…

Extending main-shaft bearing life in wind turbines

By David de Garavilla & Dr. Xiaobo Zhou SKF The renewable energy sector is being forced to reduce the levelized cost of electricity (LCoE). The wind energy industry is striving to match or exceed the LCoE of traditional energy sources. Due to the cost of the equipment combined with the lower relative operations and…

Castrol launches new Wind Academy to “up-skill” O&M techs

Castrol, a provider of lubricants to the wind energy industry, is launching the Castrol Wind Academy. The new Academy is a multi-channel training program designed to up-skill wind energy operations and maintenance (O&M) technician teams with the latest insights, technologies, processes, and examples of how best practices in O&M can improve operational efficiency, equipment life…

Three keys for choosing and analyzing gear oil in wind turbines

A wind turbine is only as reliable as the quality of its components, and this is particularly true of a turbine’s main gearbox. The job of the gearbox is to speed slow, high-torque rotation into a much faster rotation for the turbine’s generator. However, the harsh operating conditions turbines endure — including variations in wind…