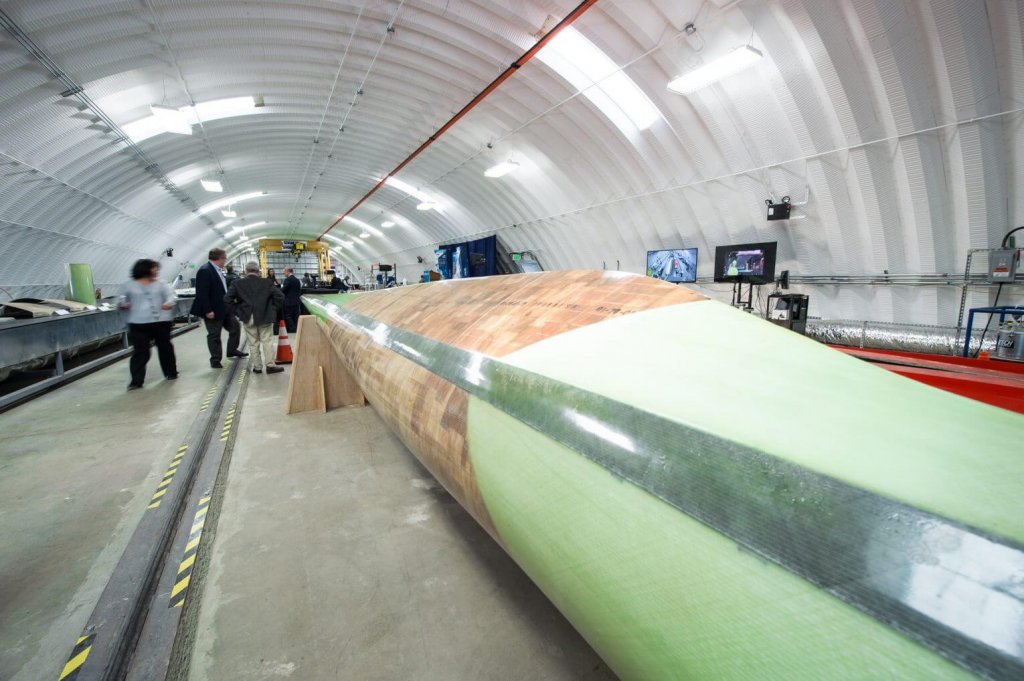

When IACMI’s Wind Technology Area Director, Derek Berry, unveiled a newly-created nine-meter wind blade at a ribbon-cutting event at National Renewable Energy Laboratory’s (NREL) Composites Manufacturing Education and Technology (CoMET) Facility at the National Wind Technology Center (NWTC) in January, over 150 people witnessed advances in composites that would change the way blades are manufactured.

The CoMET facility expedites manufacturing by letting researchers design, prototype, test and manufacturing composite wind turbine blades and other components in one place.

The innovative prototype wind blade was fabricated and assembled in the 10,000-square-foot CoMET facility. Commercialization of this blade could speed production times, reduce manufacture cost, and provide stronger, more energy-efficient blades for U.S. based wind turbines.

The CoMET facility expedites manufacturing by enabling researchers to design, prototype, test, and manufacturing composite wind turbine blades and other components in one place.

“These innovations can be deployed in the near term in existing blade manufacturing plants,” said Derek Berry, IACMI’s Wind Technology Area Director. “The ability to infuse at room temperature, demold more quickly, and avoid post cure, plus use of low-cost carbon fiber spar caps produced via high-speed protrusions, all contribute to reductions in the levelized cost of energy, the key measure of wind turbine efficiency.”

This remarkable facility is the result of a funding partnership involving NREL, IACMI-The Composites Institute and the Advanced Industries program administered by the State of Colorado’s Office of Economic Development and International Trade (OEDIT).

“This project is a perfect example of IACMI’s strength bringing together partners representing the entire industry supply chain to demonstrate the latest technologies to address cost and performance of composites,” said Bryan Dods, IACMI-The Composites Institute CEO. “Wind energy OEMs are showing great interest in the current research and development work and we anticipate continued collaboration to mature these technologies.”

After the revealing of the new blade, 300 attendees representing a record-breaking 31 different states attended the semi-annual IACMI’s Members Meeting in Denver. Colorado Governor John Hickenlooper welcomed attendees and presentations were provided by Siemens Energy, Local Motors, Dupont Polymers, IACMI HQ, The U.S. Department of Energy, State of Colorado Office of Economic Development and International Trade and many others.

The Institute for Advanced Composites Manufacturing Innovation, IACMI, is committed to delivering a public-private partnership to increase domestic production capacity, grow manufacturing, and create jobs across the US composite industry.

Filed Under: Blades, News