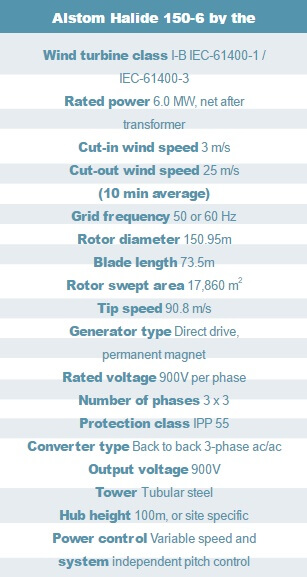

With the first U.S. offshore wind farm, Deepwater Wind, about half way through construction, what could be more appropriate than to select Alstom’s (now part of GE) Haliade 150-6 MW turbine as the Turbine of the Month? The turbine design is one of the largest in the world. (Enercon sports a 7.58-MW onshore turbine while Vestas has bragging rights to the world’s only 8-MW unit.) Designers of the U.S. wind-farm will commission five of the 6-MW turbines to provide 30 MWs total and possibly keep the diesel generators on nearby Block Island offline for long periods.

The first Haliade 150-6 MW successfully obtained the IEC power-performance measurement (power curve) after three months of testing in France. The turbine was designed following Class I-B specifications, making it suitable for sites with a reference wind speed of 50 m/s (10-minute average) and a 50-year extreme gust speed of 70 m/s (3-second average).

A few features

The turbine boasts a range of noteworthy engineering developments. For instance, like many other offshore units, this one will use a direct drive – no gearbox. GE says the generator is more compact and lighter than earlier direct-drive systems.

A feature called Alstom Pure Torque protects the generator and improves its performance by safely diverting unwanted stresses from the wind though the main frame to the turbine’s tower. It does so with a clever rotor-support concept protecting the drivetrain and other components from deflections. A patented coupling with rubber elements and an embedded hydraulic system absorb undesired loads that would otherwise affect the generator.

Other innovations keep power outputs at optimum levels. For instance, electric pitch and yaw systems control energy production. The system is said to reduce non-torque loads by 90% when compared to conventional designs. Electrical yaw and pitch controls rapidly adapt the rotor alignments to changing wind conditions to keep a nominal and constant power supply to the grid. The braking system is based mostly on pitch control. Each blade is equipped with an independent power supply to ensure safe rotor braking, even in extreme conditions.

Alstom says the Haliade 150-6MW will make maintenance as simple and as safe as possible. The hub is accessible from the nacelle, which is equipped with a 1-ton capacity crane on a central frame. A maintenance trolley inside the frame eases transport of components. Outside the nacelle, a helicopter winching area allows for quick rescue in case of an on-turbine emergency.

Other design features ensure that the turbine provides high-power production in all circumstances. For instance, three independent generator and converter lines ensure uninterrupted operations. And, the turbine can reach a yawing capacity of 95% with only six of its seven yaw motors. Software-controlled derating strategies are said to guarantee operation in the event of faults in the power line or cooling systems.

No turbine is an island, so a feature called WindAccess monitors and collects wind-farm data from other wind turbines, meteorological masts, and substations letting the facility operate like a conventional power plant. A ring-topology network connects the turbines on a facility to maintain communications even with an isolated cable fault.

Lastly, the system’s web-based interface lets operators access their wind farms from any location at any time. And the system’s open communication protocols lets the operator easily combine the wind farm with all other renewable assets in its portfolio.

Filed Under: Featured, Offshore wind