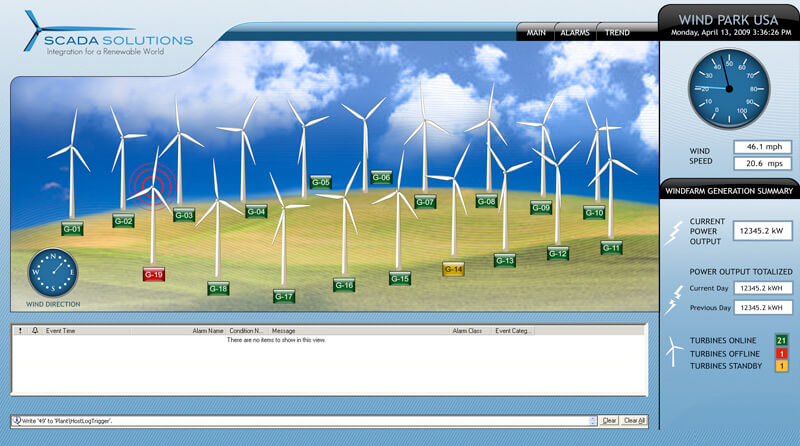

SCADA Solutions’ flagship product, WindCapture is a Supervisory Control and Data Acquisition (SCADA) software package used for monitoring, controlling and data collection and reporting for wind turbine generators. It was tailored to the demands of manufacturers, operators, developers and maintenance managers of wind energy projects and facilities.

The Challenge California is seeing strong growth in the use of wind energy, building on its success in this area during the past 30 years. For many aging wind farms and their utility owners, however, older wind turbines do not have remote monitoring and control systems that simplify curtailment when utilities must scale back power generation during periods of low demand.

“Ironically, too much electricity flowing into a state’s electrical grid can be just as disruptive as too little, hence the need for occasional curtailment,” says Craig VanWagner, engineer for SCADA Solutions, a provider of SCADA communications, automation, and integration services for wind farms through its WindCapture online monitoring and control system. New California guidelines require these older wind farms to be able to curtail whenever energy regulatory companies say so.

The problem

When the California Independent System Operator (CAISO) tells a wind farm operator it needs to curtail power production, the company has as little as five minutes to respond. Before WindCapture, the utility would have to staff the wind farm around the clock with technicians to physically turn on or off individual turbines within the required time frame or face considerable financial penalties. When the wind picked up and the grid was ready, the technicians would bring the turbines back online.

The solution

With Opto 22’s SNAP PAC industrial controllers supervising individual I/O controllers on each turbine, a wireless mesh radio network for communications, and Opto 22’s groov operator interface for mobile devices, SCADA Solutions was able to quickly develop an affordable solution to remotely monitor and automatically manage wind farm electrical power generation output down to the individual turbine.

The Opto 22-based WindCapture system lets SCADA Solutions quickly scale-back power generation during periods of low demand.

“Opto 22’s platform has proven very versatile,” VanWagner explains. “We can take the analog and digital data from the field and bring it into control software that monitors and manages the whole wind farm. Opto 22’s software application suite gives us a variety of interfaces and protocols and the ability to push OPC data to the cloud, while groov lets customers access live turbine data and control those turbines from a smartphone or other mobile device. It also makes it really easy to get in front of new customers when you show them, on their own personal phone, how they can monitor and control their wind turbines from anywhere.” SCADA Solutions has installed the Opto 22-based WindCapture system at two wind farms and is working on a third.

Benefits

VanWagner expects utility owners to see significant additional revenue from enabling wind farm control systems that automatically optimize generation for maximum revenue. He also expects substantial savings from reducing technician travel and labor costs—not to mention the benefits of the system’s preventive maintenance capability. “If at any time a turbine starts to degrade from a preestablished baseline, WindCapture can send an alert to the customer before there’s a failure,” VanWagner notes. Together, SCADA Solutions and Opto 22’s SNAP and groov solutions are helping to keep the lights on in California in a sustainable way.

Opto 22 develops and manufactures hardware and software for applications involving industrial automation and control, energy management, remote monitoring, and data acquisition. Designed and made in the U.S.A., Opto 22 products have an established reputation worldwide for ease-of-use, innovation, quality, and reliability. Opto 22 products, including the groov mobile operator interface, use standard, commercially available networking and computer technologies, and are used by automation end users, OEMs, and information technology and operations personnel in over 10,000 installations worldwide.

Filed Under: News